Micro-fluidic chip for viscosity testing, and preparation method

A technology of a microfluidic chip and a manufacturing method, which are applied in the process of producing decorative surface effects, the manufacture/assembly of piezoelectric/electrostrictive devices, and measurement devices, etc., can solve the problems affecting material deformation, limited deformation, There are no problems, such as strong operability and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

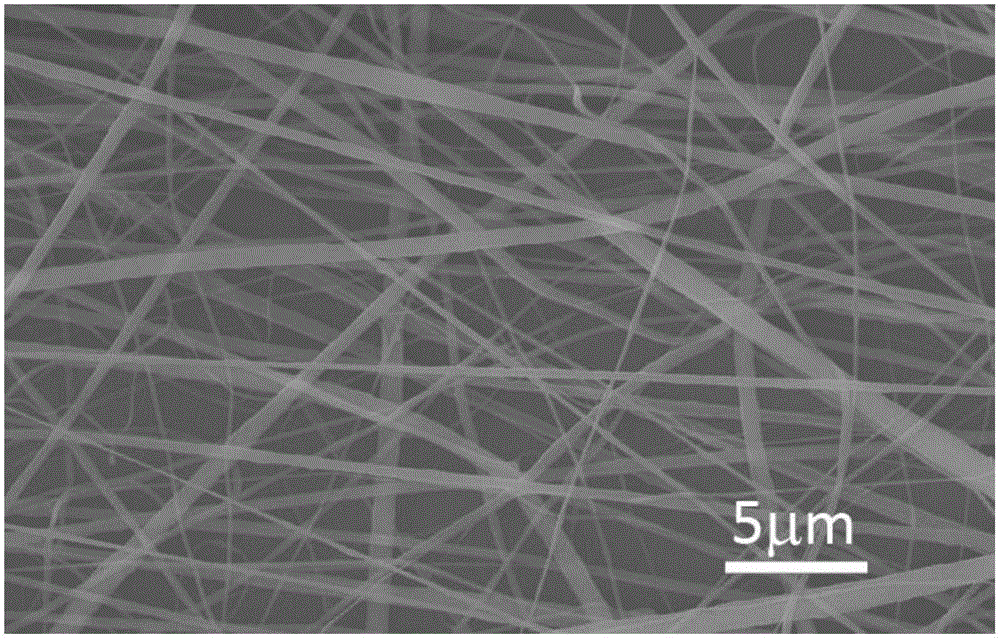

[0080] 1.1 Preparation of PVDF nanofibers by electrospinning

[0081] 1.1.1 Configuration of PVDF precursor solution: mix dimethylformamide (DMF) and acetone at a ratio of 30%:70% by volume and stir evenly; Add PVDF powder to the mixture of DMF and acetone, and seal and stir at 60°C for 60 min until the whole solution is clear and transparent.

[0082] 1.1.2 Electrospinning: Inhale the PVDF precursor solution prepared in step 1.1.1 into the syringe, install the syringe on the micro-injection pump, connect the needle of the syringe to the positive pole of the DC voltage source, and attach it to the receiving plate. Two pieces of aluminum foil are connected to the negative electrode of the DC voltage source; the direction of the needle is perpendicular to the surface of the receiving plate, the distance between the needle and the receiving plate is 15cm, the voltage of the DC voltage source is 15kV, the propulsion speed of the micro-injection pump is 50ul / min, and the ambient hu...

Embodiment 2

[0105] 2.1 Preparation of PVDF nanofibers by electrospinning

[0106] 2.1.1 Configuration of PVDF precursor solution: Mix dimethylformamide (DMF) and acetone at a ratio of 30%:70% by volume and stir evenly; Add PVDF powder to the mixture of DMF and acetone, and seal and stir at 60°C for 60 min until the whole solution is clear and transparent.

[0107] 2.1.2 Electrospinning: Inhale the PVDF precursor solution prepared in step 2.1.1 into the syringe, install the syringe on the micro-injection pump, connect the needle of the syringe to the positive pole of the DC voltage source, and attach it to the receiving plate. Two pieces of aluminum foil are connected to the negative electrode of the DC voltage source; the direction of the needle is perpendicular to the surface of the receiving plate, the distance between the needle and the receiving plate is 15cm, the voltage of the DC voltage source is 15kV, the propulsion speed of the micro-injection pump is 50ul / min, and the ambient hu...

Embodiment 3

[0130] 3.1 Preparation of PVDF nanofibers by electrospinning

[0131] 3.1.1 Configuration of PVDF precursor solution: mix dimethylformamide (DMF) and acetone at a ratio of 30%:70% by volume and stir evenly; Add PVDF powder to the mixture of DMF and acetone, and seal and stir at 60°C for 60 min until the whole solution is clear and transparent.

[0132] 3.1.2 Electrospinning: Inhale the PVDF precursor solution prepared in step 3.1.1 into the syringe, install the syringe on the micro-injection pump, connect the needle of the syringe to the positive pole of the DC voltage source, and attach it to the receiving plate. Two pieces of aluminum foil are connected to the negative electrode of the DC voltage source; the direction of the needle is perpendicular to the surface of the receiving plate, the distance between the needle and the receiving plate is 15cm, the voltage of the DC voltage source is 15kV, the propulsion speed of the micro-injection pump is 50ul / min, and the ambient hu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com