A kind of manufacturing process of enameled bare copper flat wire

A manufacturing process, technology of bare copper flat wire, applied in the field of manufacturing process of enamelled bare copper flat wire, can solve problems such as uneven paint film thickness, hidden dangers in insulation performance, insulation loss, etc., and achieve obvious surface quality and electrical performance Excellent, the effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

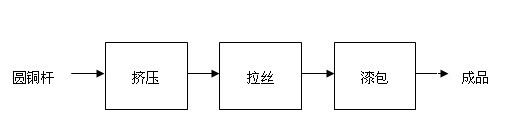

[0019] A kind of manufacturing process of enamelled bare copper flat wire of the present invention, see figure 1 , the process uses round copper rods to directly extrude bare copper flat wires, and by reducing the number of die drawing passes, enamelled bare copper flat wires that meet the requirements in terms of size, hardness, and compactness are obtained. The specific steps are as follows:

[0020] 1) Extrude the round copper rod directly to obtain a bare copper flat wire; the extrusion process is to raise the temperature of the round copper rod to about 800 degrees through frictional heat generation, and the round copper rod becomes semi-liquid, and then controls the shape through an alloy mold The size is ejected and cooled rapidly. The bare copper flat wire produced by the extrusion process has stable dimensions, smooth surface and no blemishes.

[0021] 2) The bare copper flat wire is drawn by one or two dies, so that the shape, hardness and compactness of the bare co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com