Solar cell with carbon germanium thin film as intrinsic layer and preparation method thereof

A solar cell and intrinsic layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of wide band gap and small absorption coefficient, and achieve the effects of easy operation, simple preparation process and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

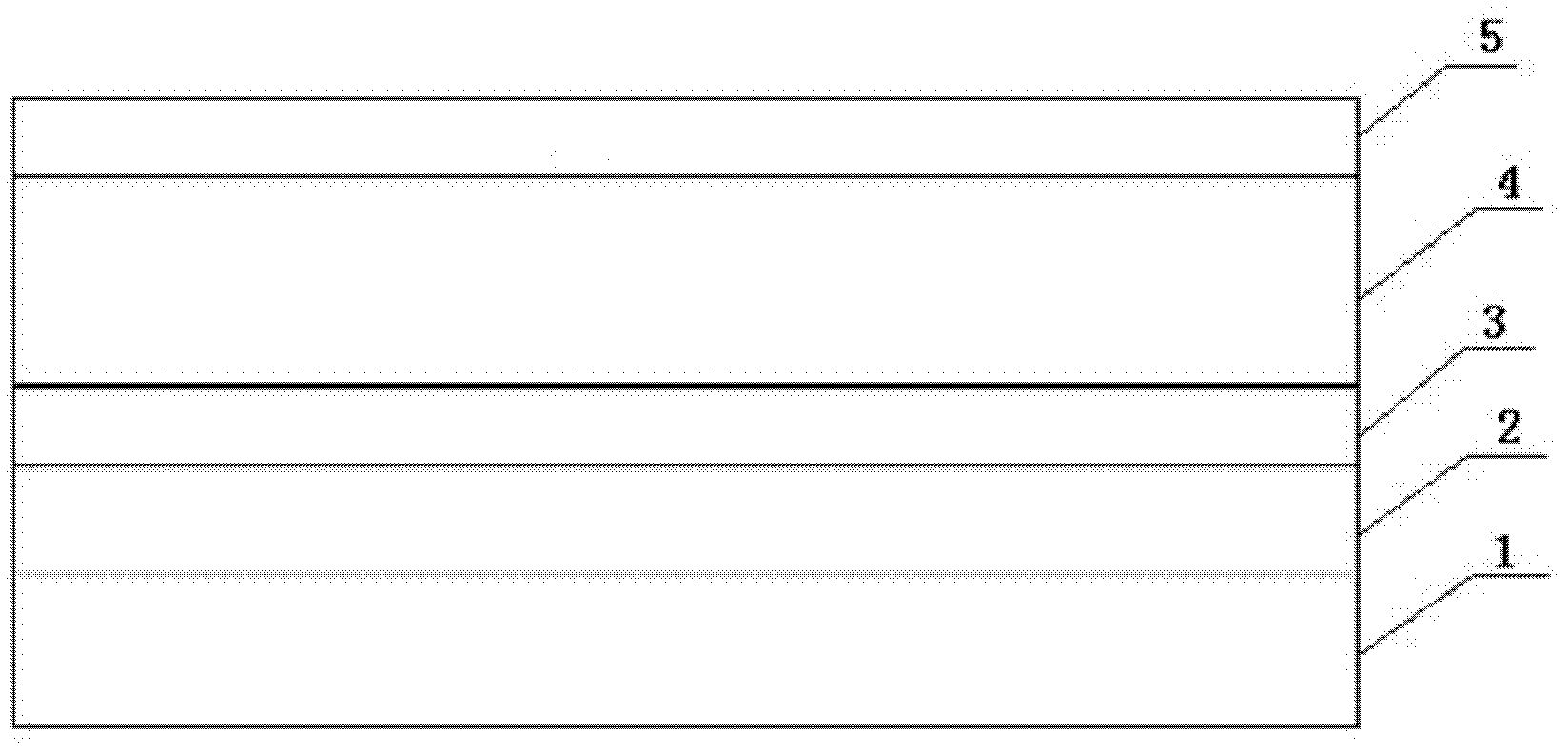

[0009] Specific implementation mode 1: Combination figure 1 This embodiment will be described. The intrinsic layer of this embodiment is a solar cell with a carbon germanium film, which includes a transparent substrate 1, a transparent conductive film 2, a P-type window layer 3, an intrinsic layer 4, and an N-type layer 5. The transparent conductive film 2 is provided on the transparent substrate. On the upper surface of the bottom 1, the P-type window layer 3 is provided on the upper surface of the transparent conductive film 2, the intrinsic layer 4 is provided on the upper surface of the P-type window layer 3, and the N-type layer 5 is provided on the upper surface of the intrinsic layer 4. On the upper surface; wherein the intrinsic layer 4 is a carbon germanium film.

[0010] figure 1 1 is a transparent substrate, 2 is a transparent conductive film, 3 is a P-type window layer, 4 is an intrinsic layer, and 5 is an N-type layer.

specific Embodiment approach 2

[0011] Specific embodiment 2: Specific embodiment 1 The method for preparing a solar cell whose intrinsic layer is a carbon germanium thin film is carried out according to the following steps: 1. The transparent substrate 1 is coated with a conductive transparent electric film 2; The transparent conductive film 2 on the substrate 1 is coated with a P-type window layer 3; 3. The transparent substrate 1 with the transparent conductive film 2 and the P-type window layer 3 is ultrasonically cleaned with acetone for 15-30 minutes, and then the quality The percentage concentration is 99.5% ethanol solution for 15-30 minutes, and finally with deionized water for 15-30 minutes; 4. The transparent substrate 1 with transparent conductive film 2 and P-type window layer 3 processed in step 3 In the vacuum degree is 1.0×10 -4 ~9.9×10 -4 Under the condition of Pa, heat to 25~700℃, then keep for 10~120 minutes and then pass in argon gas, and then under the condition of 3~5 Pa, the upper surfac...

specific Embodiment approach 3

[0013] Specific embodiment three: This embodiment is different from the specific embodiment two in that the ultrasonic cleaning in step three is 15 minutes. Others are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com