Battery liquid injection device and liquid injection method

A liquid injection device and battery technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of low liquid injection efficiency, slow operation speed, limitations, etc., and achieve high liquid injection efficiency, improve efficiency, and continuous. The effect of a high degree of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

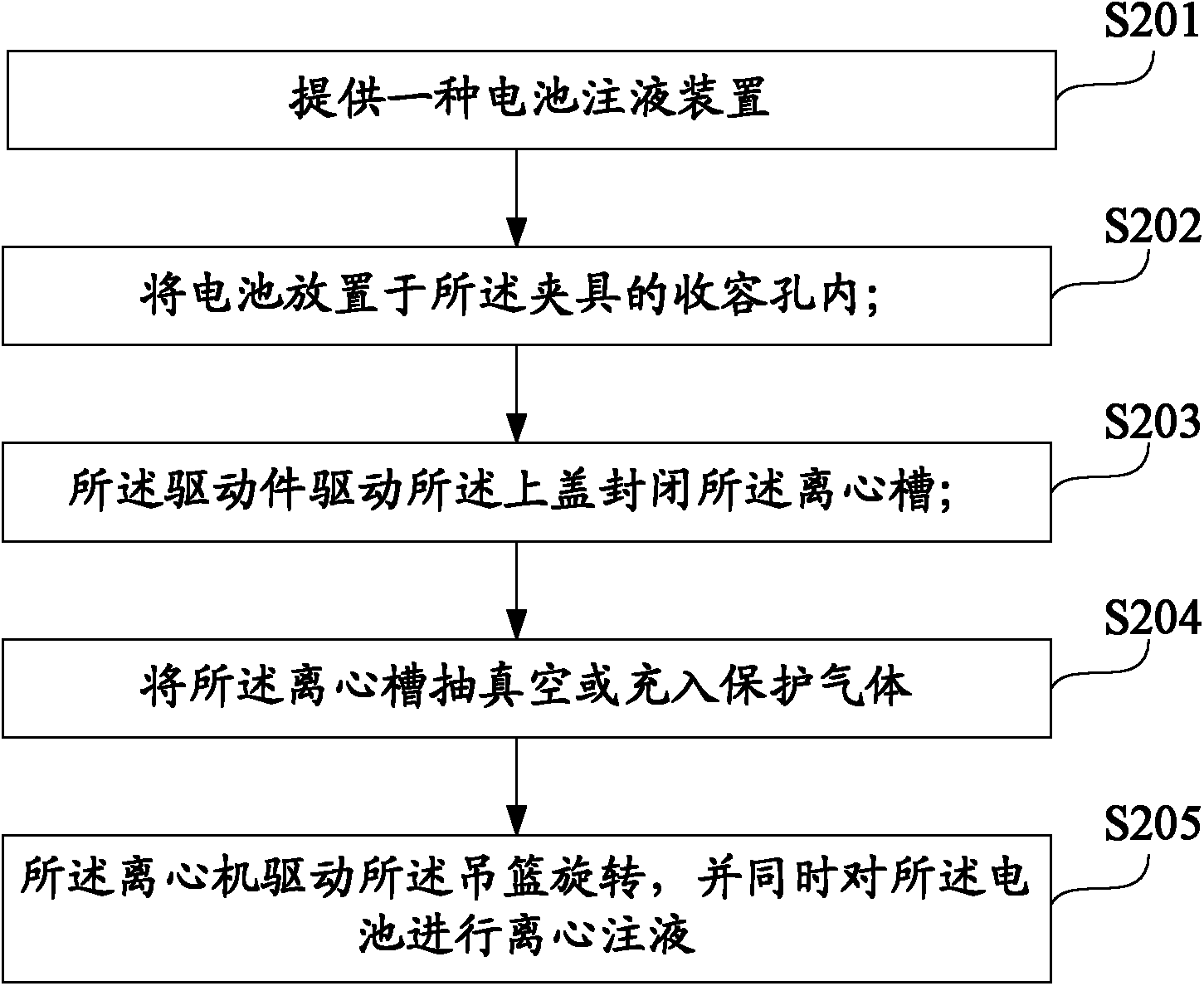

[0026] The specific embodiments of the present invention will be described below mainly in conjunction with the accompanying drawings.

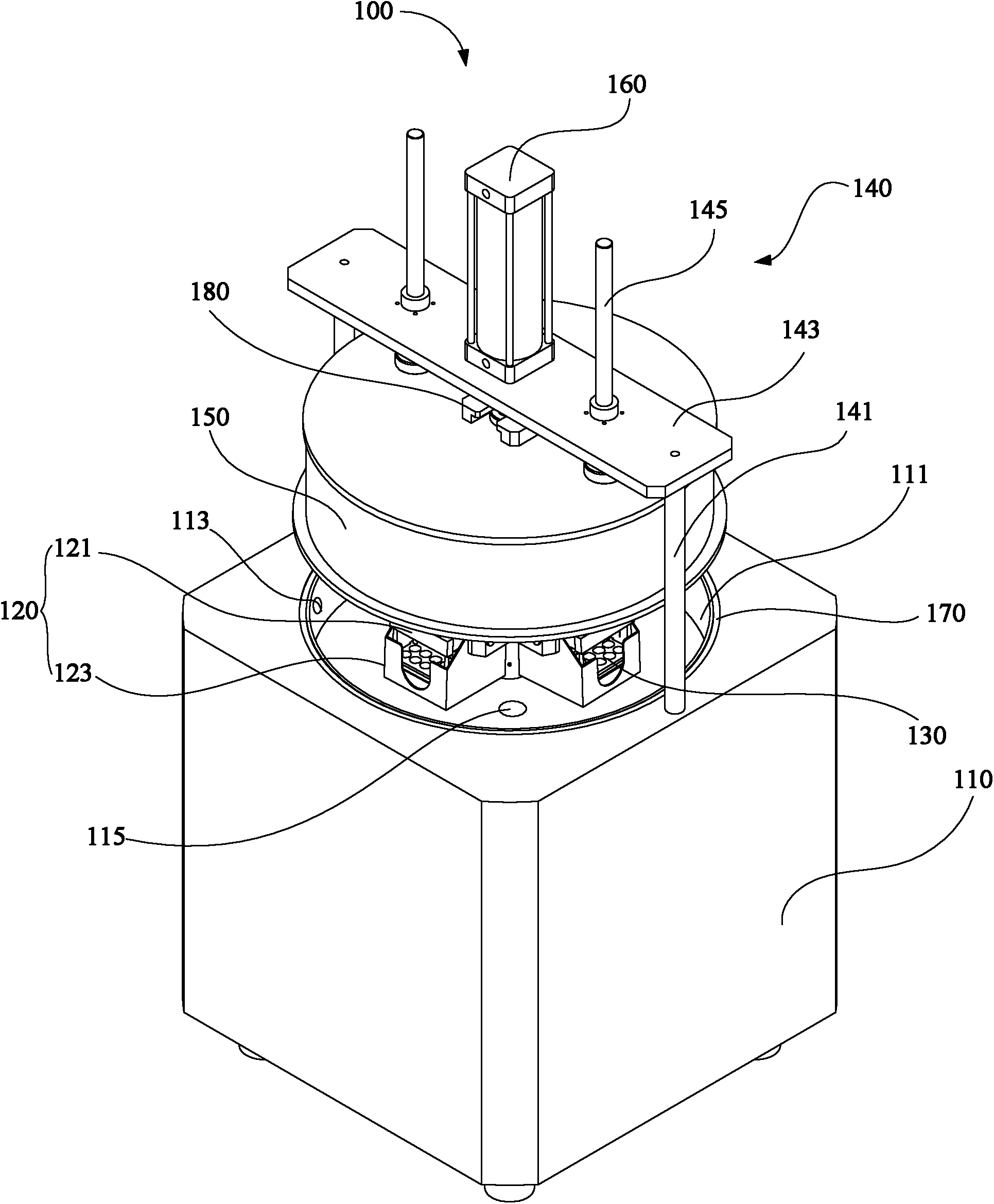

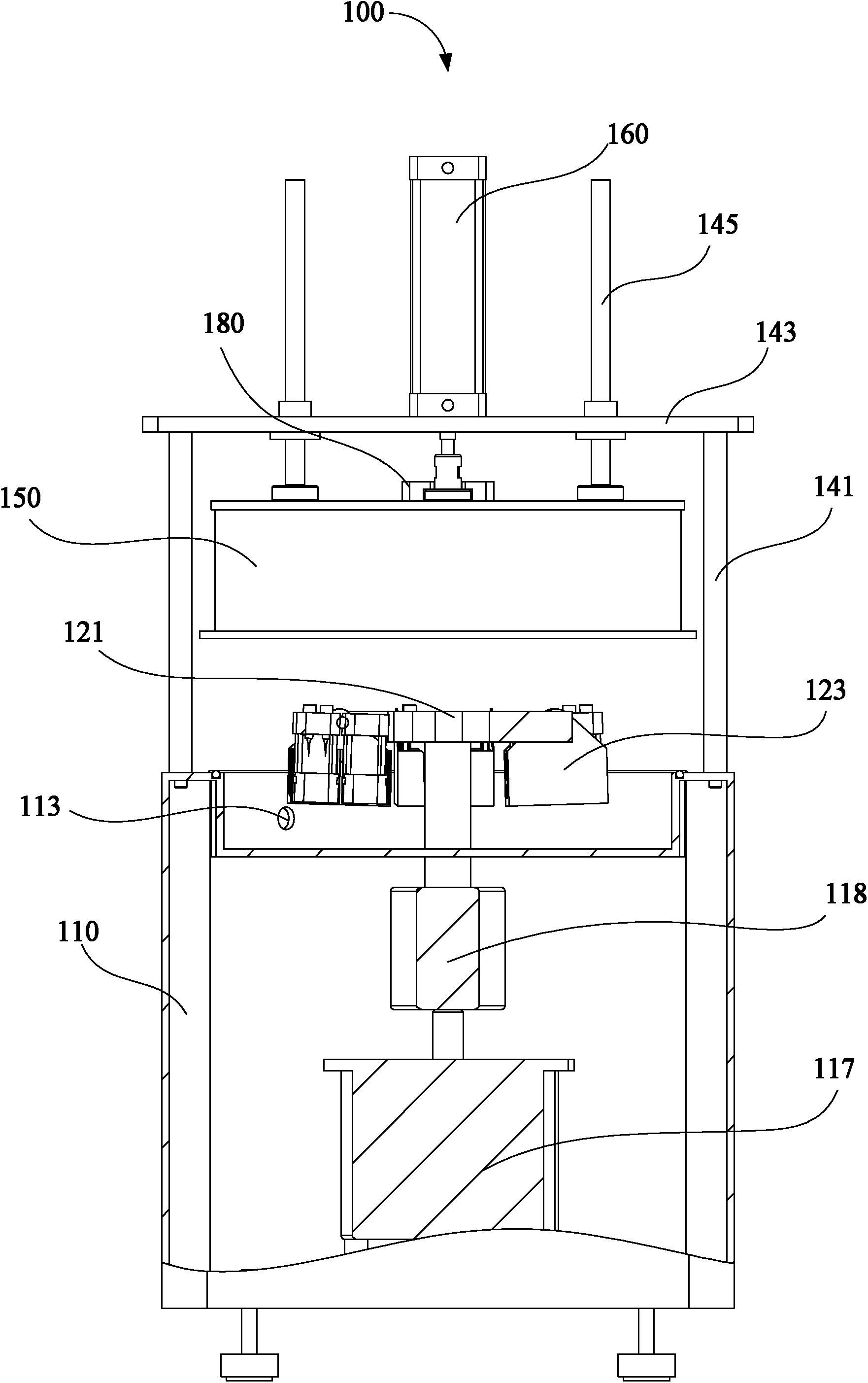

[0027] see figure 1 and figure 2 , The battery liquid injection device 100 of this embodiment is used to inject the electrolyte into the battery, which includes a centrifuge 110 , a hanging basket 120 , a clamp 130 , a support base 140 , an upper cover 150 and a driving member 160 .

[0028] The centrifuge 110 has a centrifuge tank 111 . The centrifuge tank 111 is approximately cylindrical.

[0029] The hanging basket 120 is accommodated in the centrifugal tank 111 of the centrifuge 110 , and the centrifuge 110 can drive the hanging basket 120 to rotate. Specifically, in this embodiment, the hanging basket 120 includes a fixing bracket 121 and a plurality of storage boxes 123 fixed on the periphery of the fixing bracket 121 , and the clamp 130 can be placed in the storage boxes 123 .

[0030] It can be understood that the hanging basket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com