Concentrate for preparing infant skin care product and application thereof

A technology of skin care and concentrated solution, which is applied in the field of preparation of baby skin care products, can solve the problems of unsuitable production methods, high cost, and long time required, and achieve excellent smoothness, refreshment and moisturizing feeling, and is convenient The effect of flexible and convenient production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

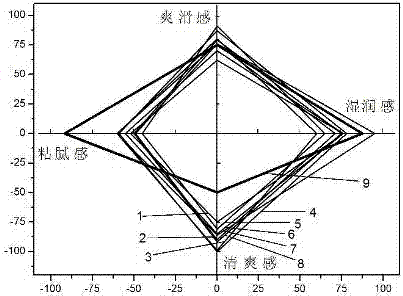

Image

Examples

Embodiment 1

[0056] 1# to 8# concentrates (see Table 1 for the formula) are prepared as follows: ① Mix components A), B) and D) and heat to 80°C, keep it warm for half an hour, and use it as an oil phase; ② Mix components C) Heat it to 80°C separately, keep it warm for half an hour, and use it as the water phase; ③ After the emulsification tank is heated to 80°C, add 2 / 3 of the water phase to the emulsification tank, then pump all the oil phase in, and then pump the remaining water phase Add, stir at high speed, homogenize for 5-10 minutes, emulsify completely, keep warm for half an hour; add E) component after cooling down to 40°C.

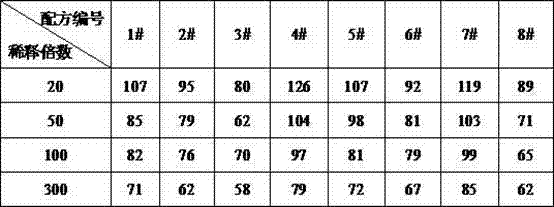

[0057] Table 1. Feeding amount of each formula

[0058]

Embodiment 2

[0060] With reference to standard QB / T2286-1997, observe the stability of 1# to 8# concentrated solution in the embodiment 1, the results are shown in Table 2, as seen the heat resistance of the concentrated solution of the present invention, cold resistance and centrifugal test all meet standard requirements, have Very good stability.

[0061] recipe number heat resistance cold resistance centrifuge test 1# no separation no separation no layering 2# no separation no separation no layering 3# no separation no separation no layering 4# no separation no separation no layering 5# no separation no separation no layering 6# no separation no separation no layering 7# no separation no separation no layering 8# no separation no separation no layering

Embodiment 3

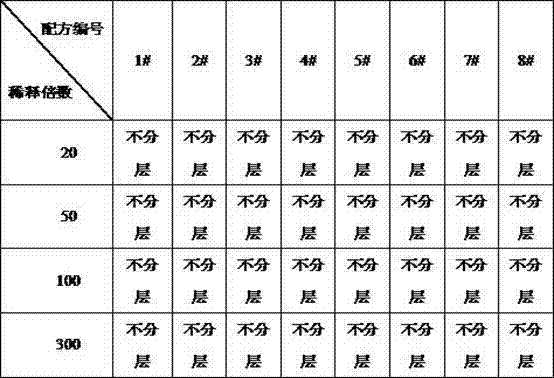

[0063] Diluent stability, after diluting 1# to 8# concentrated solution in embodiment 1 20~300 times, do centrifuge test with reference to standard QB / T2286-1997, the results are shown in Table 3, as seen the diluent of concentrated solution of the present invention has no separation. Layer phenomenon, with good stability.

[0064] Table 3. Stability of Diluents

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com