A kind of ball mill less ball milling method

A ball mill and mill technology, applied in grain processing and other directions, can solve the problem of improving grinding efficiency, such as the inconspicuous steel balls of ball mills, and achieve the effects of saving power consumption, improving efficiency and reducing power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

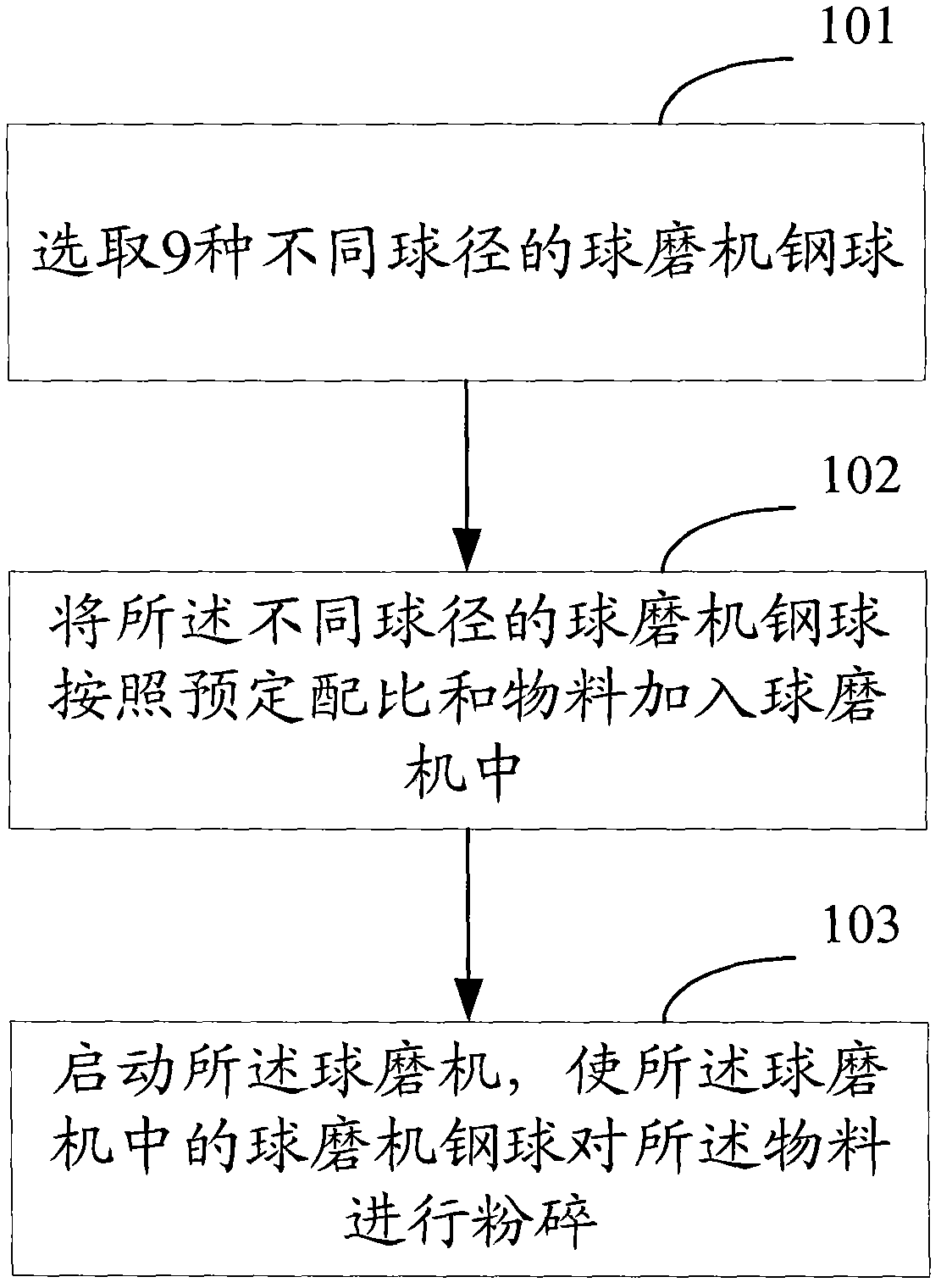

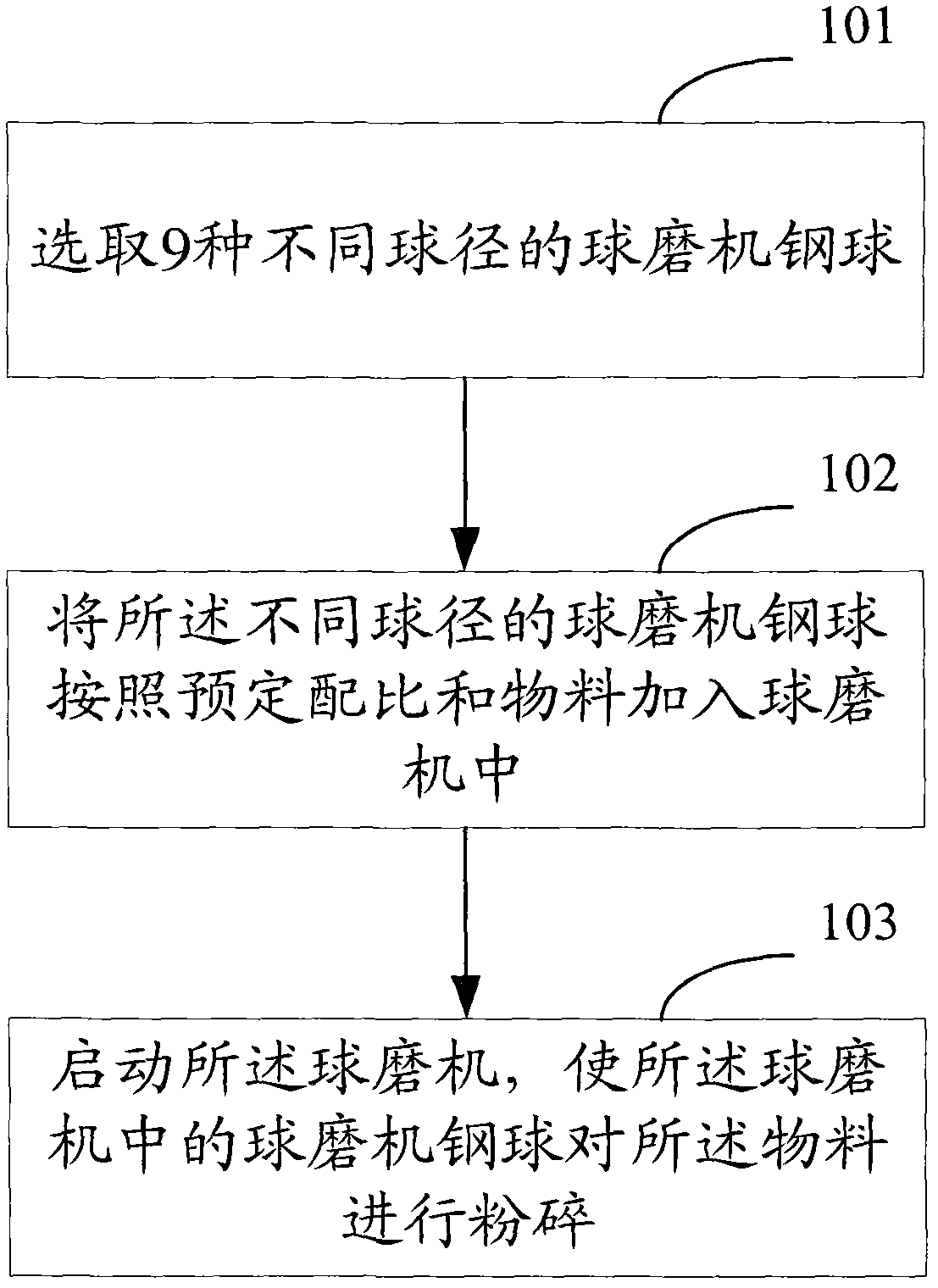

[0031] The present invention proposes a ball mill less-ball grinding method, which is applied in a ball mill that uses ball mill steel balls to pulverize materials. The method is as follows: figure 1 As shown, including the following steps:

[0032] Step 101: Select 9 kinds of ball mill steel balls with different ball diameters, namely 20 mm, 25 mm, 30 mm, 40 mm, 50 mm, 60 mm, 70 mm, 80 mm, and 90 mm.

[0033] The above-mentioned ball mill steel balls are specially treated chromium-manganese tungsten grinding balls. Compared with ordinary ball mill steel balls, their hardness and wear resistance are greatly improved, creating conditions for the use of small balls (ball diameters less than 30 mm) in the ball mill As the number or surface area of the small balls increases or increases significantly, the action point or area of the grinding increases or increases, and the grinding efficiency is also greatly improved.

[0034] Step 102, adding the ball mill steel balls with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com