Resin molding transfer process forming method and mold for cable fairing

A technology for a cable fairing and a forming method, which is applied in the coating and other directions, can solve the problems of dry spots, air bubbles, poor glue, etc., and achieves the effects of low production cost, reliable processability, and good damage safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

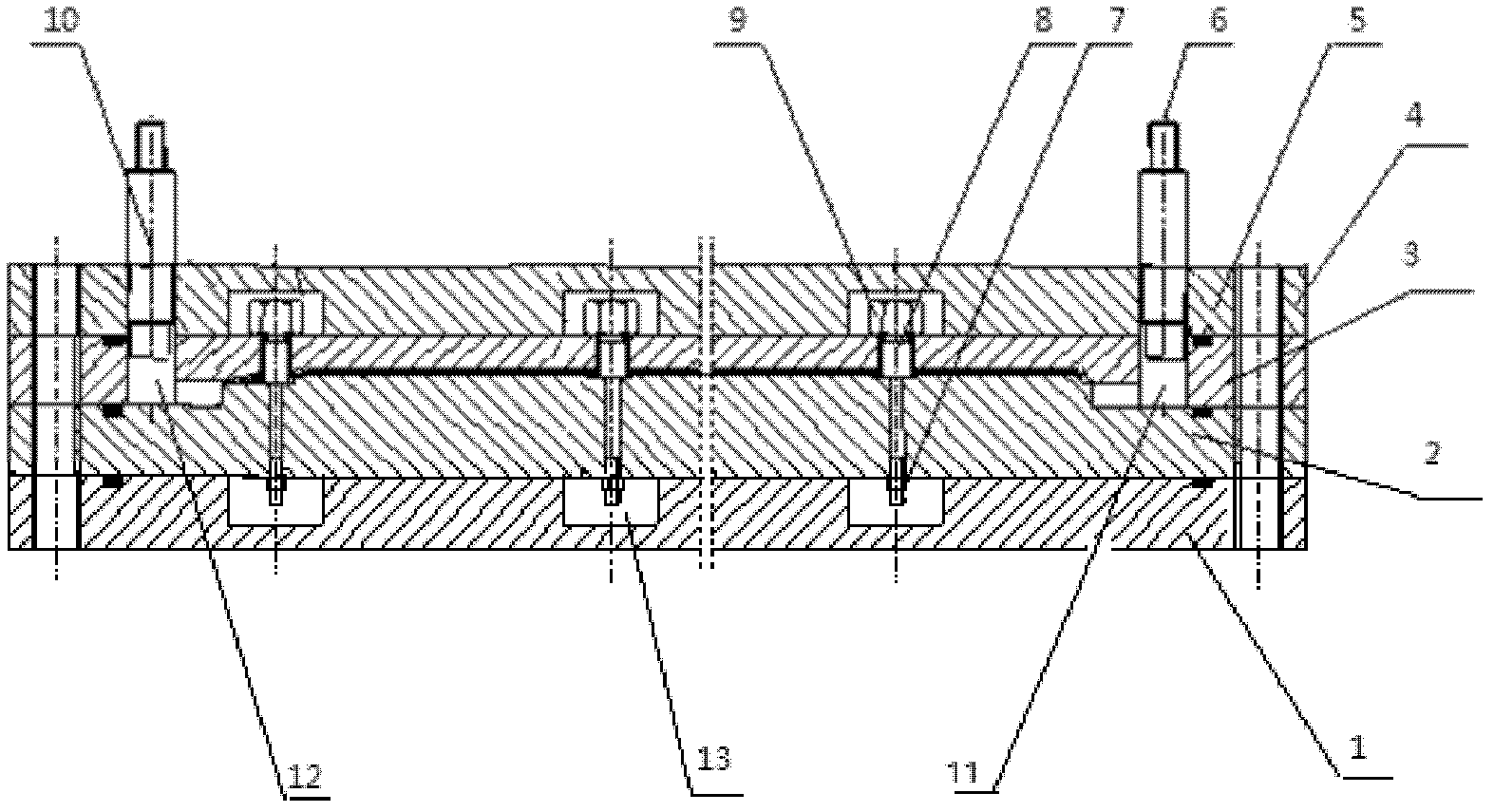

[0027] Such as image 3 As shown, the mold embodiment includes a lower platen 1, a punch 2, a die 3, an upper platen 4, a sealing ring 5, a glue injection joint 6, a small nut 7, a screw rod 8, a large nut 9, and a glue joint 10.

[0028] The lower end of the die 3 connected to the glue injection joint 6 is provided with a glue flow groove 13 at the holes of the upper platen 4 and the corresponding metal sheet parts on the lower platen 1, and the edge part of the bottom of the punch 2 and the edge of the bottom of the die 3 Rectangular sealing grooves are respectively provided on the contact surfaces of the part and the lower platen 1 and the punch 2, which can play a sealing role after the molds are closed. A glue injection port 11 and a glue outlet 12 are arranged on the upper platen 4, and the glue injection port 11 and the glue outlet 12 can also be used for vacuuming. The punch 2 and the die 3 are provided with connecting holes for installing the large nut 9, the screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com