An improved device for the air thimble of a horizontal cake making machine

A gas cap and horizontal technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of dust entering the cylinder, unusable, stuck, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

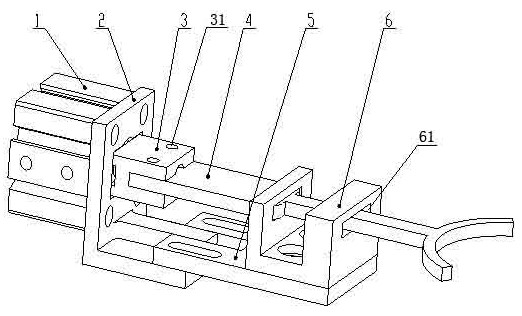

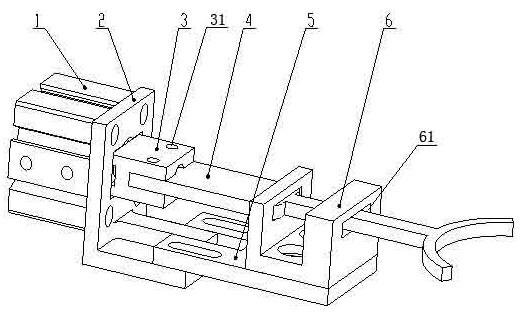

[0015] figure 1 The air thimble improvement device of a horizontal cake making machine is shown, comprising a cylinder 1 and a cylinder support 2, the cylinder support 2 is L-shaped, the cylinder 1 is arranged on the outside of the cylinder support 2, and the inner lower part of the cylinder support 2 is arranged There is a base 5, on which a guide bracket 6 is fixedly arranged, and the vertical end of the guide bracket 6 is provided with a guide hole 61, and the function of the guide hole 61 is to fix the direction of the guide rod 4, so as to prevent the guide rod from being caused by the operation of the cylinder 1. 4 fluctuates up and down, thus causing wear to the product, the cylinder 1 is fixedly connected to a guide rod 4 through the connector 3, and the other end of the guide rod 4 passes through the guide hole 61.

[0016] Further, the cylinder 1 is a double-action thin cylinder without a pressure relief port, which prevents dust from entering the cylinder 1 during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com