Method for treating sulfuric acid wastewater in the production process of poly-p-phenylene terephthalamide fiber and its treatment device

A poly(p-phenylene terephthalamide) and production process technology are applied in the field of sulfuric acid wastewater treatment, can solve the problems of unrealistic use, high cost, concentration and recovery of difficult-to-contain sulfuric acid wastewater, etc., and achieve convenient operation and saving cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

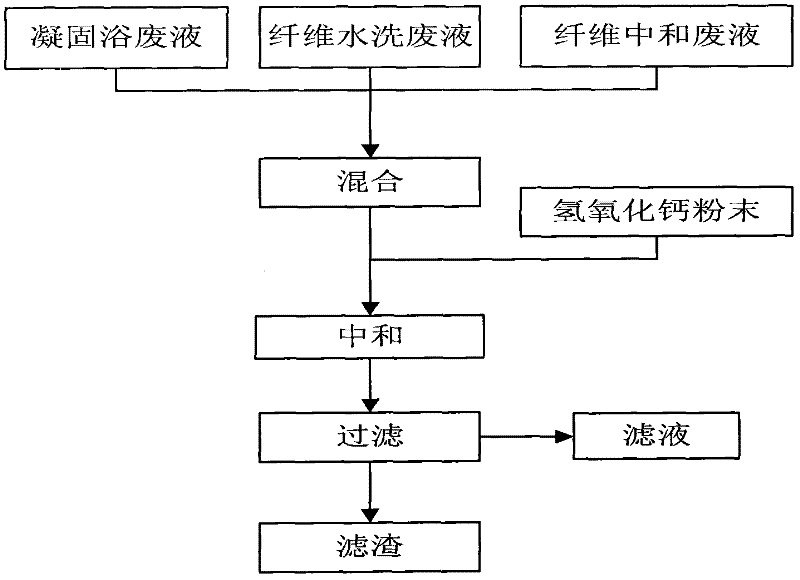

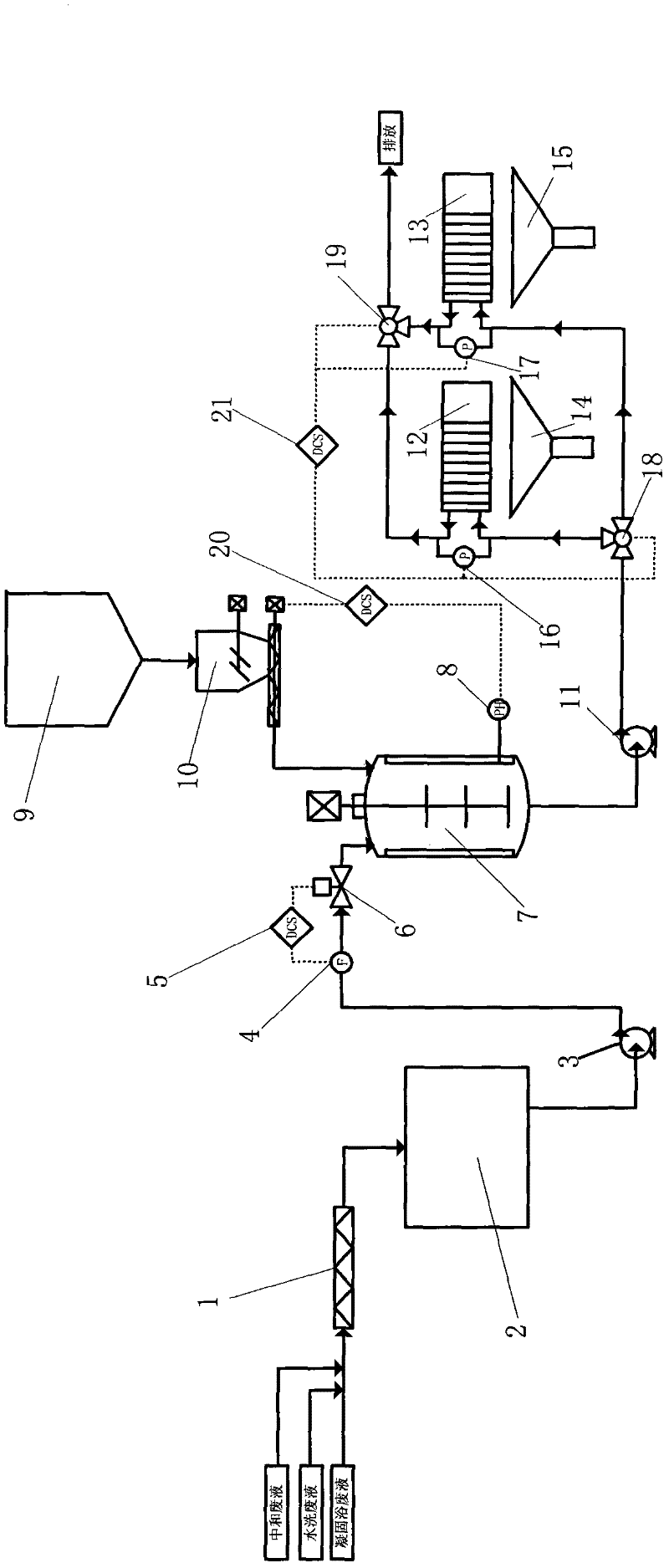

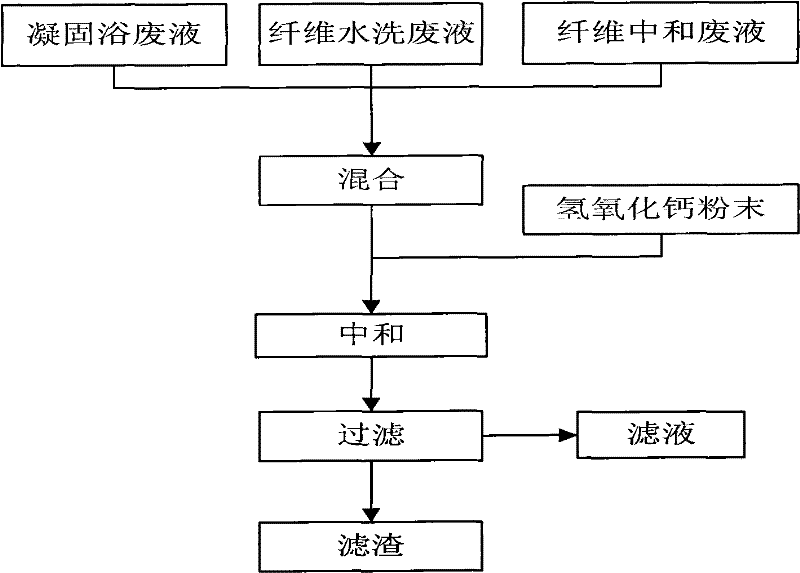

[0023] The flow rate of coagulation bath waste liquid is 4300kg / h, the flow rate of fiber washing waste liquid is 8100kg / h and the flow rate of fiber neutralization waste liquid is 6200kg / h. After mixing through the static mixer, it flows into 100m 3 Waste liquid storage tank, the waste liquid in the waste liquid storage tank is continuously sent to 20m by a centrifugal pump at a flow rate of 18600kg / h and calcium hydroxide powder of 450kg / h 3 In the neutralization reactor, stir and react for 1 hour, the pH value measured by the online pH meter is 7.5, and the neutralized waste liquid is pumped into the filter area of 400m by the neutralization waste liquid delivery pump at a flow rate of 19050kg / h 2 , In the plate and frame filter with a filtration accuracy of 40u, the filtrate is discharged as industrial wastewater, and the filter residue is discharged into the filter residue hopper.

Embodiment 2

[0025] The flow rate of coagulation bath waste liquid is 2150kg / h, the flow rate of fiber washing waste liquid is 4050kg / h and the flow rate of fiber neutralization waste liquid is 3100kg / h. After mixing through a static mixer, it flows into 100m 3 Waste liquid storage tank, the waste liquid in the waste liquid storage tank is continuously sent to 20m by a centrifugal pump at a flow rate of 9300kg / h and calcium hydroxide powder of 225kg / h 3 In the neutralization reactor, stir and react for 2 hours, the pH value measured by the online pH meter is 7.1, and the neutralized waste liquid is pumped into the filter area of 400m by the neutralization waste liquid delivery pump at a flow rate of 9525kg / h 2 , In the plate and frame filter with a filtration accuracy of 40u, the filtrate is discharged as industrial wastewater, and the filter residue is discharged into the filter residue hopper.

Embodiment 3

[0027] The flow rate of coagulation bath waste liquid is 860kg / h, the flow rate of fiber washing waste liquid is 1620kg / h and the flow rate of fiber neutralization waste liquid is 1240kg / h. After mixing through the static mixer, it flows into 100m 3 Waste liquid storage tank, the waste liquid in the waste liquid storage tank is continuously sent to 20m by a centrifugal pump at a flow rate of 3720kg / h and calcium hydroxide powder of 90kg / h 3 In the neutralization reactor, stir and react for 5 hours, the pH value measured by the online pH meter is 8, and the neutralized waste liquid is pumped into the filter area of 400m by the neutralization waste liquid delivery pump at a flow rate of 3810kg / h 2 , In the plate and frame filter with a filtration accuracy of 40u, the filtrate is discharged as industrial wastewater, and the filter residue is discharged into the filter residue hopper.

[0028] A collection of names of the components that make up the device:

[0029] 1. Static m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com