Solar constant pressure heating hot airflow engine generation system

A power generation system, solar technology, applied in solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., can solve the problems of dish solar thermal power generation without demonstration power stations and insufficient research, and achieve low cost and good stability , The effect of high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

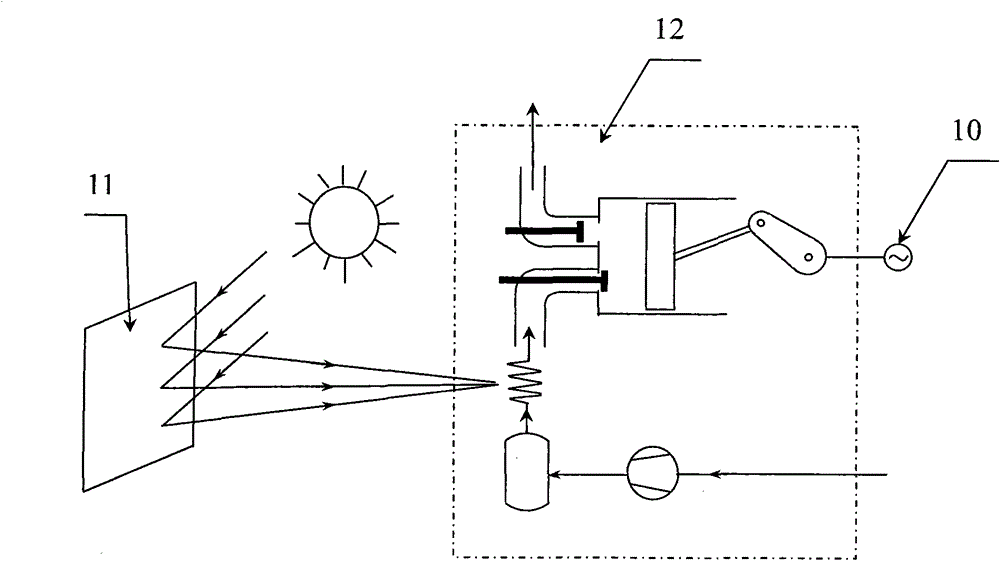

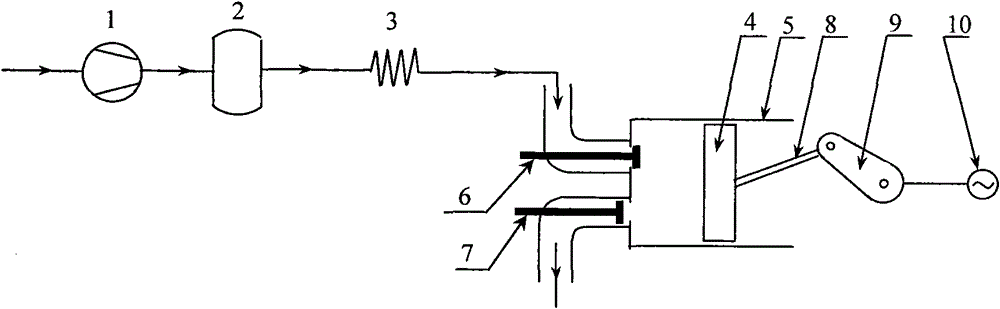

[0016] Refer to attached figure 2 , 3 , 4, the present invention comprises biaxial tracking solar energy focusing mirror system 11, solar energy constant pressure heating power conversion unit (hot air flow engine) 12, generator 10, solar energy constant pressure heating power conversion unit 12 is composed of air compressor 1, gas storage Tank 2, solar absorber 3, output shaft work cylinder assembly, output shaft work cylinder assembly includes cylinder 5, piston 4, connecting rod 8 and crank 9, air inlet and exhaust port, air inlet and outlet provided on cylinder 5 The intake valve 6 installed on the port, the exhaust valve 7 installed on the exhaust port, the solar absorber 3 is a heat exchanger, which can be a cavity type solar absorber, air compressor 1, gas storage tank 2, solar absorber 3 Connect the gas pipes in series with the air inlet, the output shaft power cylinder 5 is equipped with a piston 4, the piston 4 is connected to the crank 9 through the connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com