Multi-state gas-liquid optical fiber sensor for simultaneous detection of pressure, temperature and component concentration

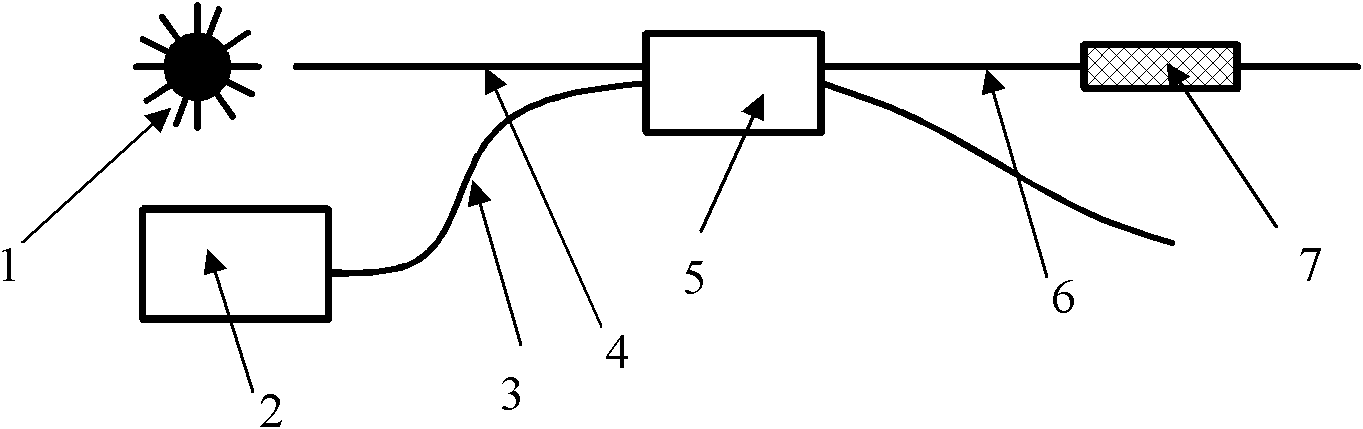

An optical fiber sensor and optical fiber technology, applied in thermometers, thermometers with physical/chemical changes, fluid pressure measurement using optical methods, etc., to achieve the effects of good fidelity, strong correlation, and convenient space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

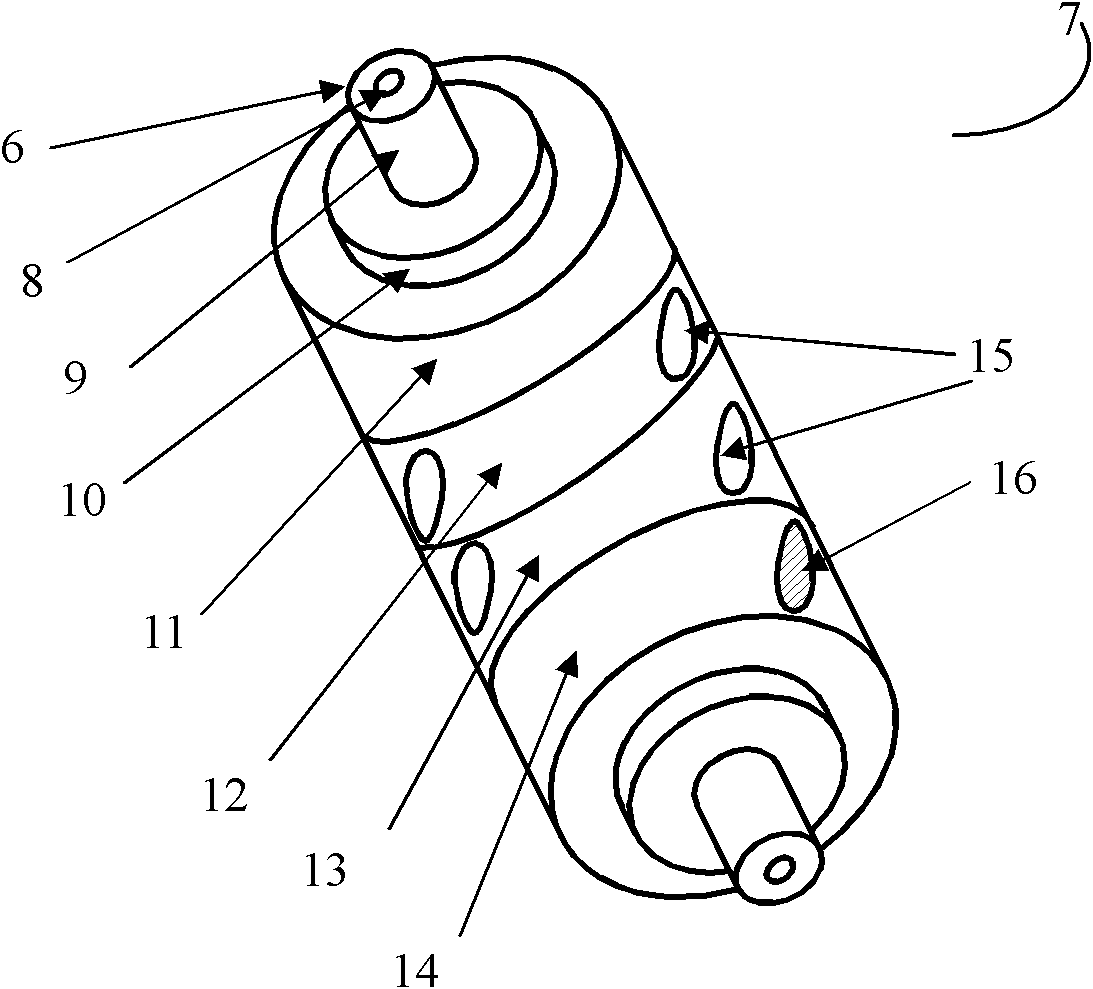

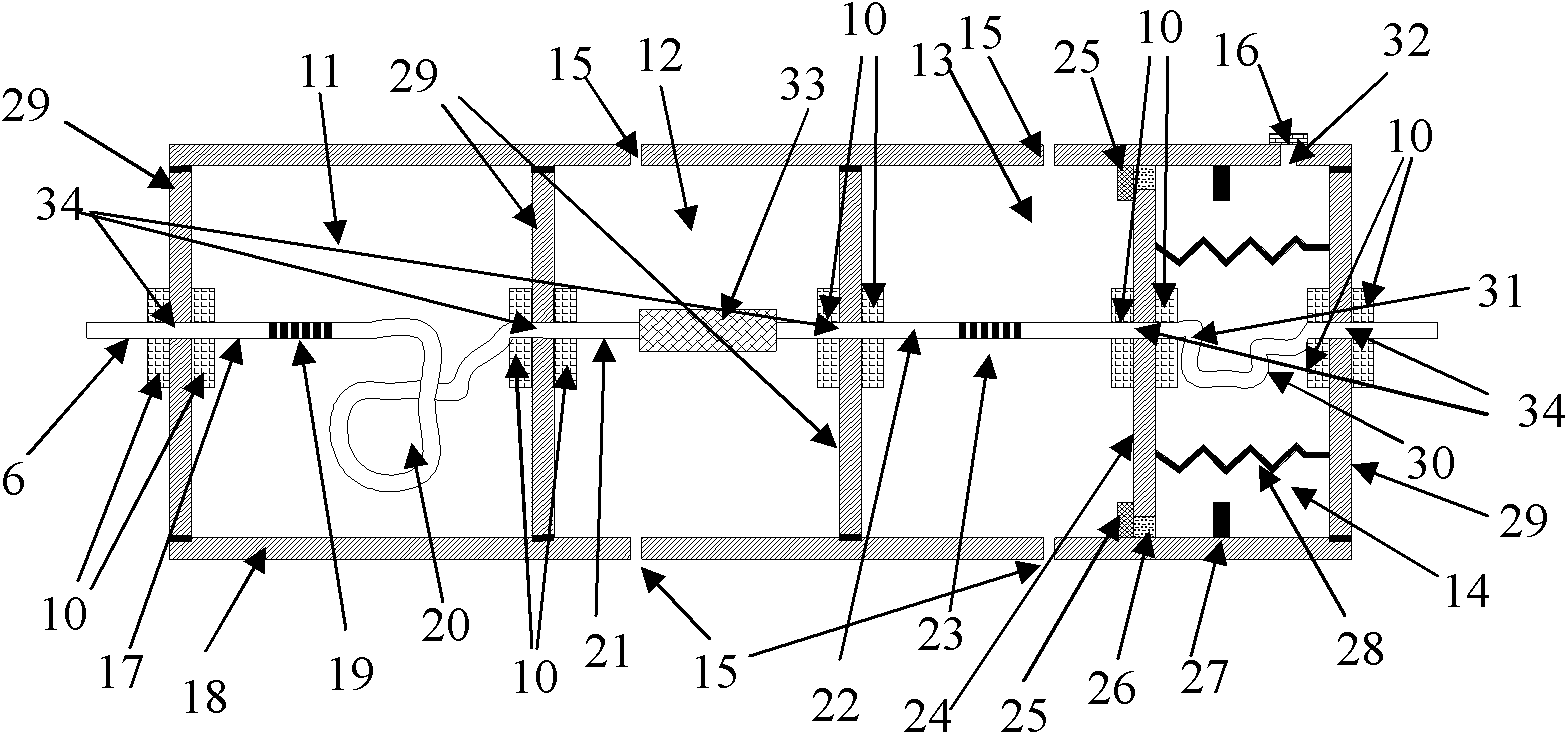

[0043] 1. Take an optical fiber with a cladding diameter of 250 μm, a core diameter of 9 μm, and a length of 200 cm, and use it as the second light-guiding optical fiber 6. Write fiber Bragg gratings at two places 50 cm and 150 cm away from its ends, and write the fiber length of the grating segment 10mm. The reflection wavelength 1520nm of the first fiber Bragg grating 19, the reflection wavelength 1555nm of the second fiber Bragg grating 23, on a section of optical fiber with a length of 20mm in the middle of the optical fiber, remove the optical fiber protection layer 9 and the optical fiber cladding, then in its exposed fiber core A hydrogen sensitive film-tungsten trioxide film layer is deposited on it, and the modified optical fiber segment is the evanescent field sensing area 33 of the sensing optical fiber probe 7 .

[0044] 2. Process the sleeve 18 with an inner diameter of 30mm, a length of 110cm, and a wall thickness of 3mm. Processing 5 diameter 29mm, the fixed ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com