Liquid crystal display device

A liquid crystal display device and liquid crystal layer technology, applied in optics, instruments, electrical components, etc., can solve the problem that the common electrode line cannot meet the requirements of high aperture ratio, and achieve the effects of reducing production cost, simplifying manufacturing process, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

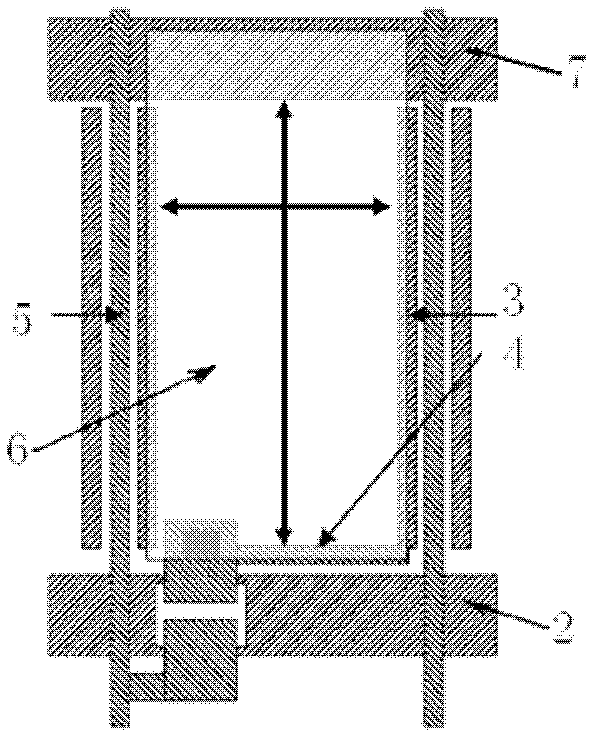

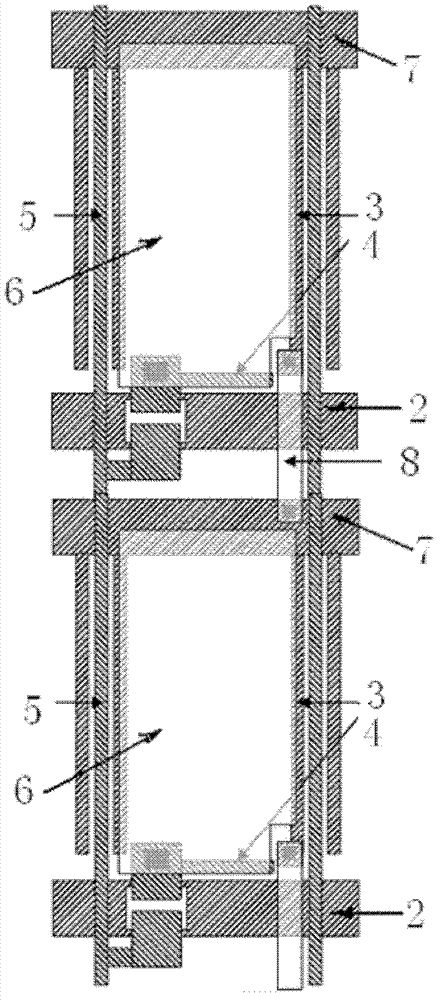

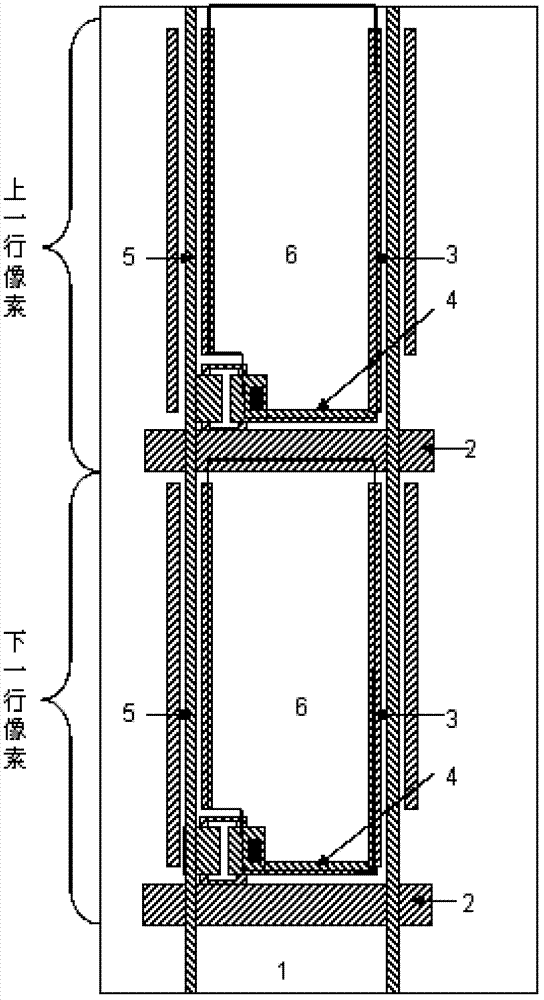

[0042] After adopting the scheme of the present invention, an embodiment of the TN pixel is as follows image 3 shown. For the convenience of description, the figure shows the overall structure of the combination of the upper row of pixels and the lower row of pixels.

[0043] exist image 3 In , the outermost box surrounding the pixel structure represents the underlying common electrode, which uses transparent materials such as ITO and ZnO. The transparent bottom common electrode is directly formed on the glass substrate by sputtering process. The sheet resistance of the bottom common electrode can be controlled by adjusting sputtering process parameters, film thickness and other items. After the film forming process of the bottom common electrode is completed, a transparent first insulating layer, such as a SiNx layer, SiO2 layer, etc., is then formed. The subsequent manufacturing method is compatible with the existing process: the scanning line 2 pattern, the second ins...

Embodiment 2

[0049] The IPS pixel structure adopting the scheme of the present invention is similar to the pixel structure of FFS, specifically as Figure 6 shown. The difference is that in the FFS pixel structure, the underlying common electrodes are distributed in blocks in each pixel, and the potential of the lower common electrode squares is introduced through the common electrodes.

Embodiment 3

[0051] The VA pixel structure adopting the scheme of the present invention is similar to the TN pixel structure, specifically as Figure 7 shown. The difference is that the pixel electrode 6 of the VA structure is divided into a ">" or "<" shape by the slit 11Slit.

[0052] The potential of the bottom common electrode in the solution of the present invention is introduced at the position of Seal16 outside the display area. Potential introduction position such as Figure 8 As shown: a large-area contact hole 9 is designed around the display area at a position corresponding to the sealing glue Seal16. Through these contact holes 9, the common electrode potential input from the outside of the substrate can be introduced to the bottom common electrode. The specific design embodiment on the position of contact hole 9 can be as follows Figure 9 As shown: the bottom of the contact hole 9 is respectively covered with the metal layer connected to the potential of the common electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com