A Calibration Method for Parameters of Finite Parallel First-Order Reaction Hydrocarbon Kinetic Model

A technology of model parameters and hydrocarbon dynamics, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that cannot be used to approximately describe the hydrocarbon formation process of organic matter, and cannot approximately reflect the kerogen bond type composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

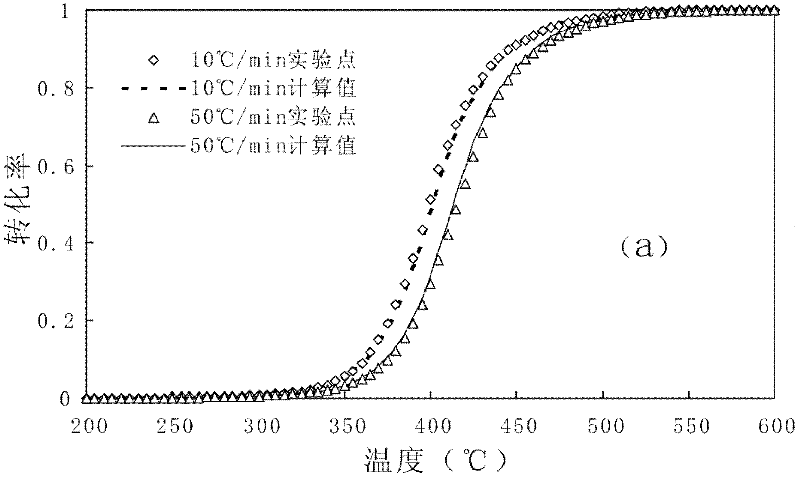

[0111] Example 1: Taking the calibration of the thermal simulation experiment parameters of the mudstone of Well Du 13 in the Songliao Basin as an example, the calibration method of the parameters of the finite parallel first-order reaction hydrocarbon generation kinetic model is described in more detail.

[0112] Table 1 Information of mudstone samples in Well Du13

[0113]

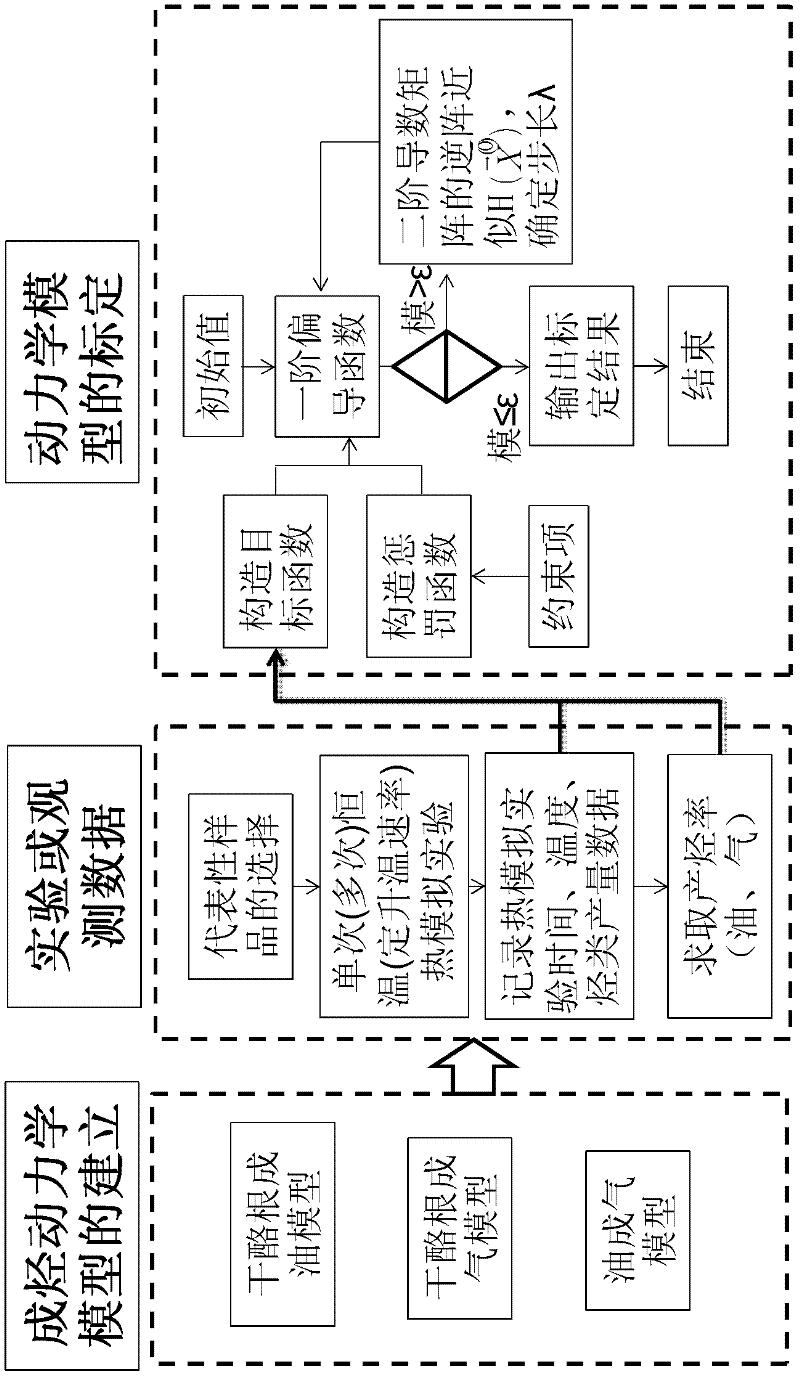

[0114] For specific steps, see figure 1 :

[0115] Step 1: Construct the chemical kinetic model of kerogen to oil

[0116] XO = Σ i = 1 NO XO i = Σ i = 1 NO ( XO i 0 ( 1 - exp ...

Embodiment 2

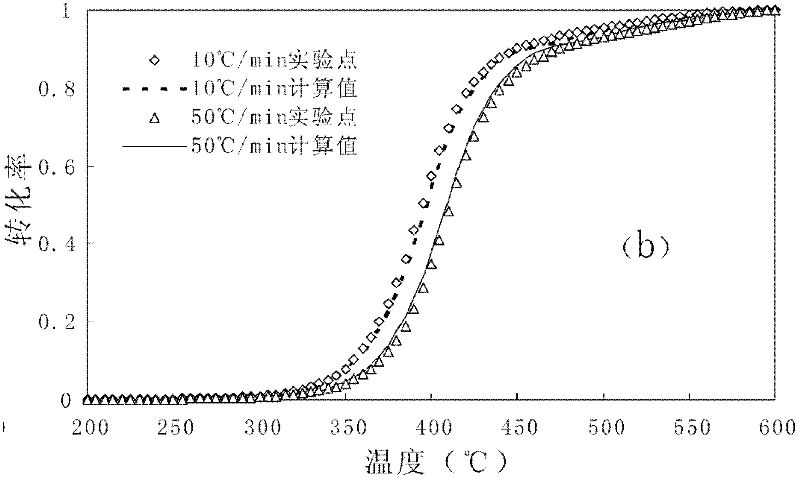

[0158] Example 2: Taking the calibration of the thermal simulation experiment parameters of crude oil in Lunnan 57 Well as an example, the calibration method of the parameters of the finite parallel first-order reaction hydrocarbon formation kinetic model is described in more detail.

[0159] Table 2 Sample information

[0160] area

the depth

C(%)

H(%)

N(%)

S(%)

O(%)

Tarim Basin

Marine crude oil

85.16

14.37

0.67

-

<0.3

[0161] The difference between embodiment 2 and embodiment 1 is that the gold tube thermal simulation experiment under the closed system is used to obtain the experimental parameters, and the main calibration is the cracking of crude oil into an aerodynamic model, namely:

[0162] XG = Σ i = 1 NG XG ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com