A cooling device for improving the power generation capacity of photovoltaic cells

A photovoltaic cell and cooling device technology, applied in photovoltaic power generation, photovoltaic modules, circuits, etc., can solve the problems of burning out chips, reducing power generation efficiency, water and electricity consumption, etc., achieving strong heat absorption and heat dissipation capabilities, efficient and rapid heat dissipation. The effect of reducing and improving the power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

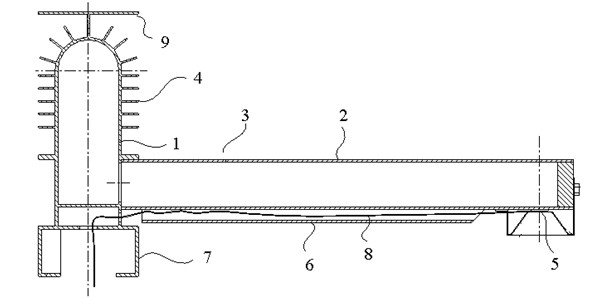

[0017] like figure 1 As shown, the cooling device for improving the power generation capacity of photovoltaic cells is a T-shaped heat dissipation pipe 3 composed of interconnected main pipes 1 and side pipes 2; a cooling medium is passed through the T-shaped heat dissipation pipe 3, and cooling fins are provided on the main pipe 1 The sheet 4 is provided with a bracket 5 for placing photovoltaic cells on the side pipe 2 . A sun visor 9 is provided on the main pipe 1 . The bracket 5 is arranged under the side pipe 7 , and the side pipe 2 is provided with a hole 6 for placing the conductive wire 8 of the photovoltaic cell. A junction box 7 is provided below the main pipe 1 .

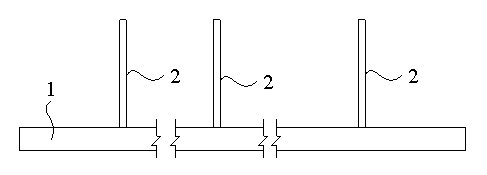

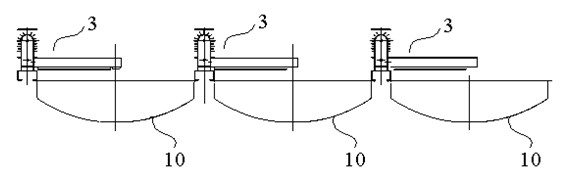

[0018] like figure 2 and image 3 As shown, in actual use, the number of T-shaped cooling pipes 3 can be set according to the number of modules. When there is only one reflecting mirror 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com