A pure lead gel battery

A technology of colloidal batteries and colloidal electrolytes, which is applied in the direction of lead-acid batteries, electrode carriers/collectors, etc., can solve the problems of low porosity of PVC separators, large internal resistance of fixed colloidal electrolytes, and easy overflow of electrolytes, etc. Large rate discharge capability, guaranteed charge and discharge reaction efficiency, and superior charge reception capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

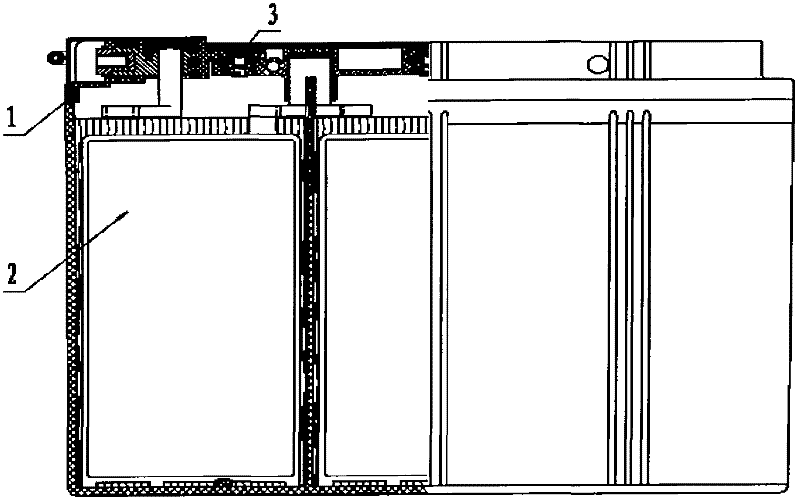

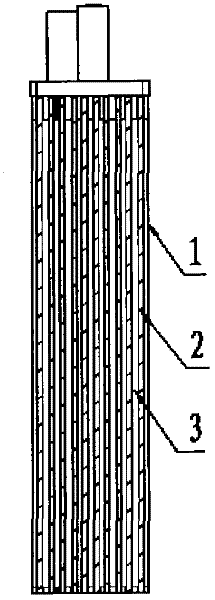

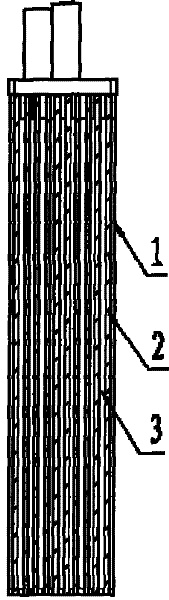

[0011] A pure lead colloidal storage battery, mainly comprising a square shell, a positive grid, a positive plate 3, a negative grid, a negative plate 1, a silicon phosphogel colloidal electrolyte; a PVC separator is sandwiched between the positive plate 3 and the negative plate 1 2, and the surface near the positive electrode is covered with a separator; the thickness of the positive grid is 2.0mm, and the thickness of the negative grid is 1.0mm, both of which are pure lead-lead plates; the thickness of the positive plate 3 is 2.4mm, and the thickness of the negative plate 1 is 1.4mm; Plate 2 is PVC and nano-silica polymer microporous material, and has a glass fiber adsorption layer on its surface opposite to the positive grid, with a thickness of 1.8mm; the silicon-phosphocolloid colloidal electrolyte includes the following components by weight: nanometer 18% of silicon dioxide powder, 0.5% of adsorbent, 4% of stabilizer, 0.2% of additive, and the balance is acid and water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com