A rotor double-winding structure of a megawatt doubly-fed wind turbine

A wind turbine, megawatt-level technology, applied in the field of motor windings, can solve the problems of poor reliability, many hoods, and poor power generation quality, and achieve the effects of increased leakage reactance, short pitch, and fewer turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

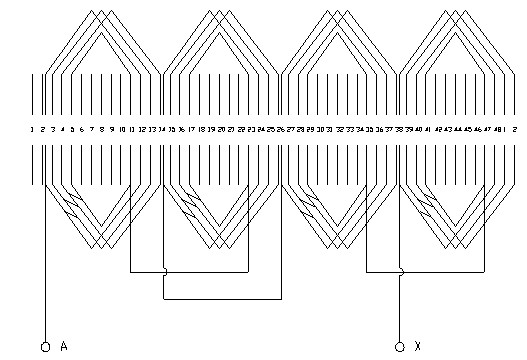

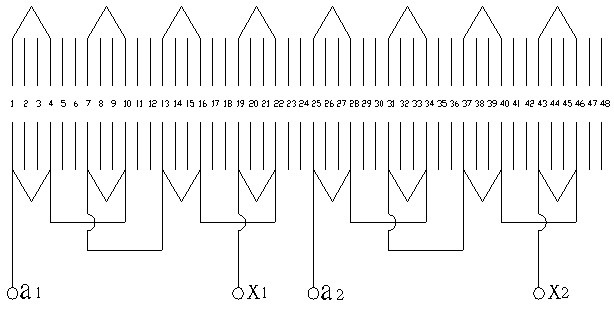

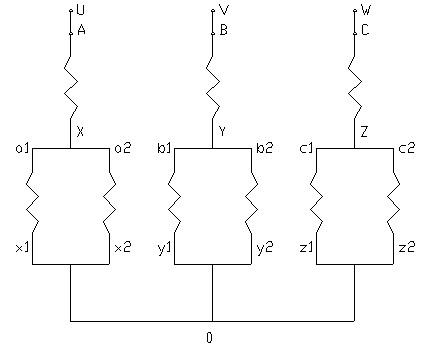

[0015] Example 1 is attached Figure 1-3 Shown: A megawatt-class double-fed wind generator implements a 4-pole 1.5MW double-fed wind generator with a voltage of 690V and a rotor double-winding structure; the number of slots in the rotor coil is 48 slots, and the slot shape of the rotor coil slot is originally It is a semi-open slot with a slot width of 8mm. It adopts double-layer wave winding hard coils with equal pitch. The number of conductors in each slot is 4. Now the slot shape of the rotor coil slot is changed to a semi-closed flat-bottomed slot. Two sets of three-phase symmetrical overlapping loose-embedded soft windings are arranged in the rotor coil slot; figure 1 The first set of three-phase windings is shown as the excitation working winding, and its structure is a double-layer stacked winding with unequal turns and unequal distances. Each phase is composed of 4 sets of windings in series, and each set has 4 windings. The pitch of 3 coils is 10, the pitch of 1 coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com