Magnetic powder vacuum mixer

A vacuum mixing and agitator technology, applied in mixers, mixer accessories, mixers with rotary mixing devices, etc., can solve problems such as waste, increase production costs, environmental pollution, etc., achieve uniform distribution of binders, and save production costs. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

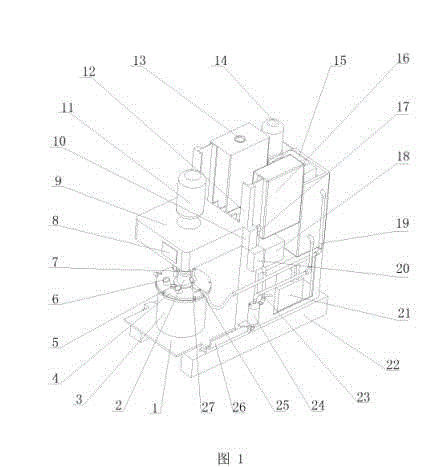

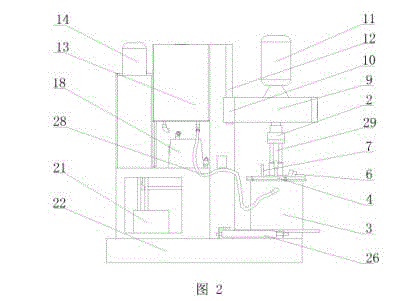

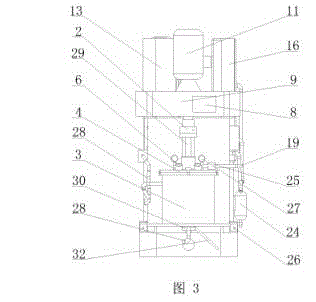

[0027] A magnetic powder vacuum mixing mixer, such as Figure 1-Figure 5 As shown, it includes a frame 22 and a mixing device, a hydraulic drive device, a condensate recovery system, a heating device and an electric control device arranged on the frame 22 .

[0028] The mixing device comprises a feed bin 3 installed on the frame 22, an elevating table 9 arranged on the top of the elevating table 3, a main motor 11 installed on the top surface of the elevating table 9, a transmission shaft 29 connected with the main motor 11 transmission, A stirring mechanism 31 connected to the lower end of the transmission shaft 29, a bin cover 4 arranged on the bin 3, and a discharge port 30 arranged at the bottom of the bin 3. The power transmission shaft 29 vertically runs through the lifting platform 9 and the silo cover 4 . Drive shaft 29 periphery is provided with connector 2, and the upper end of connector 2 is connected with lifting platform 9 bottom surfaces, and the lower end of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com