An automatic rotary cutting machine

A feeder and automatic technology, which is applied in the direction of shearing device, pipe shearing device, and accessories of shearing machines, etc., can solve the problems of difficult clamping of pipes, heavy load of driving motor, and existence of danger, etc., to eliminate potential risks and reduce Requirements, the effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

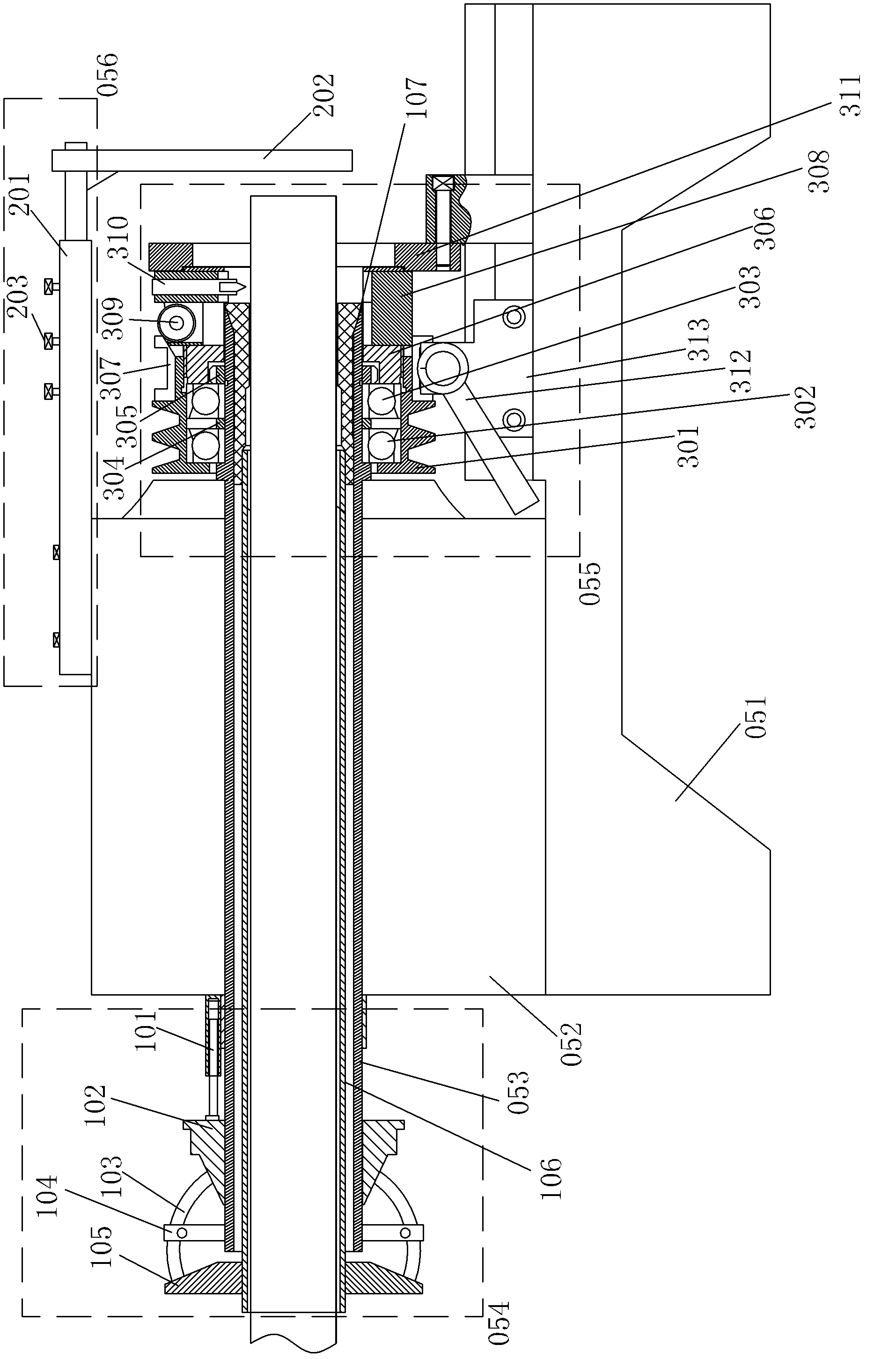

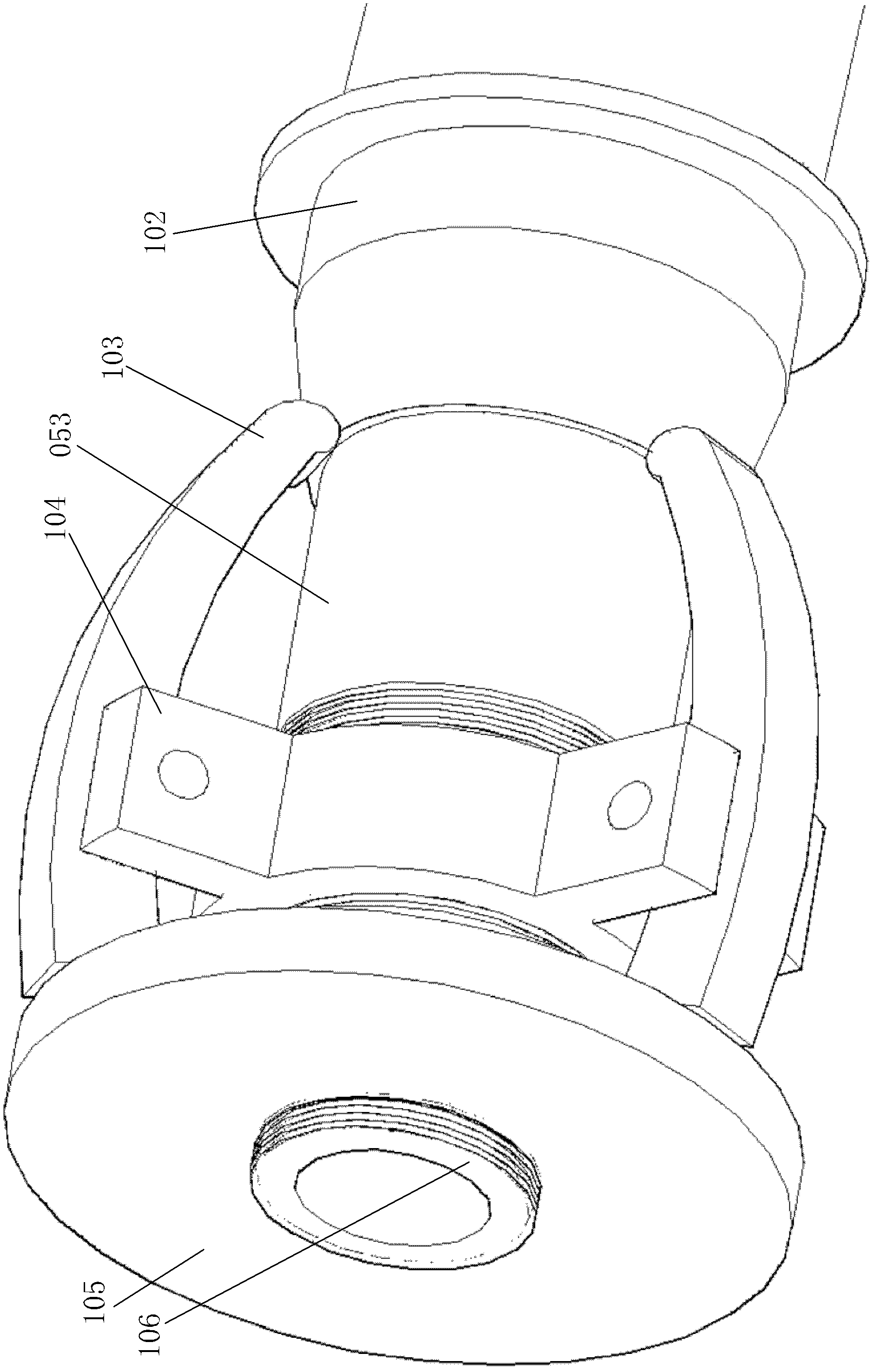

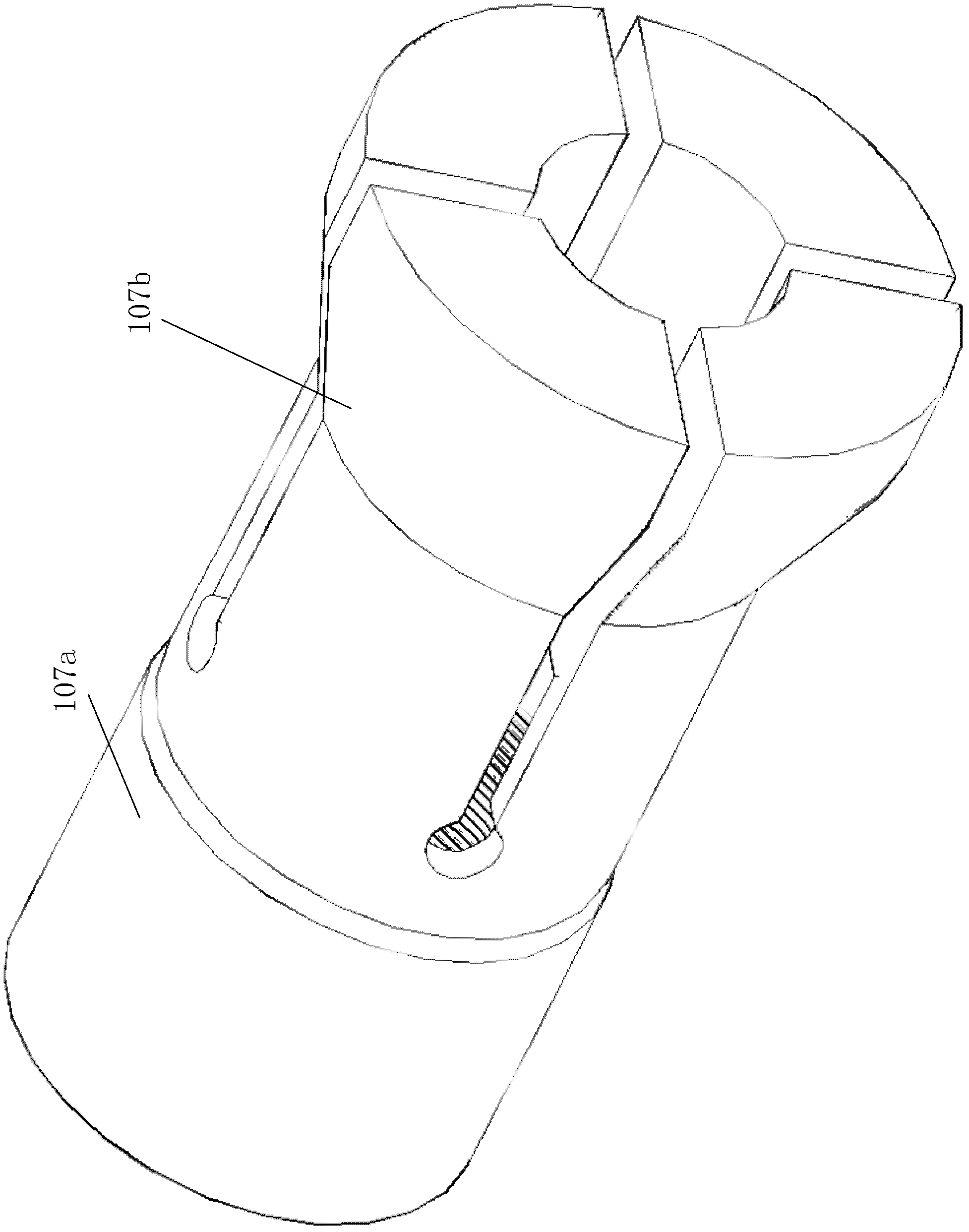

[0020] Such as Figure 1 to Figure 3 As shown, this embodiment includes a control circuit, a driving motor, a machine tool 051, an equipment fixing frame 052, a hollow spindle 053, a clamping device 054, a rotary cutting device 055 and a positioning device 056, and the equipment fixing frame 052 is fixedly installed on the machine tool 051. The hollow main shaft 053 runs through the left and right sides of the equipment fixing frame 052 from left to right and is fixedly connected on the equipment fixing bracket 052. The inner diameter of the hollow main shaft 053 gradually increases near the right end surface, forming a conical cavity. An annular protrusion 053a is provided on the outer wall near the right end of the hollow main shaft 053, and its cross-sectional shape is rectangular. The clamping device 054 is installed on the left end of the hollow main shaft 053, the rotary cutting device 055 is installed on the right end of the hollow main shaft 053, the positioning device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com