Technology for manufacturing marker on surface of ceramic material

A ceramic material, surface marking technology, applied in the direction of burning, etc., can solve the problems of unstable dye, difficult printing, low printing pattern or text accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

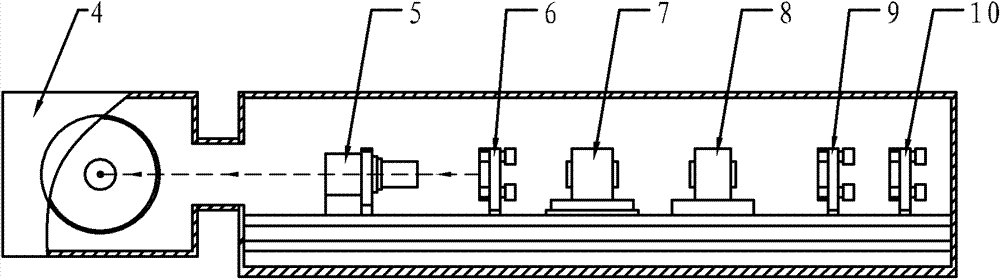

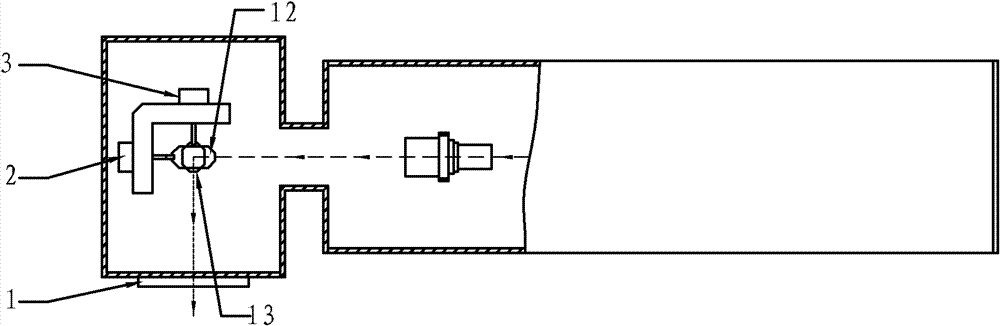

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0028] see figure 1 as well as figure 2 , the functions of each part in the laser burning equipment used in this embodiment are as follows:

[0029] Red light source 10: the red light power supply generates red light;

[0030] Total reflection mirror 9: fully reflect the red light;

[0031] Acousto-optic Q switch 8: Using the principle of acousto-optic diffraction to modulate the continuous Nd:YAG laser into a pulsed laser with high peak power;

[0032] The Nd:YAG laser resonator is composed of DPL semiconductor module 7 and the front and rear diaphragm cavity mirrors, and cooperates with the water cooling system to generate laser light together;

[0033] Partial reflector 6: reflect the laser light generated by the YAG condenser cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com