A device and method for MBR membrane fouling control

A membrane fouling and sewage technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of avoiding membrane fouling, improving resistance to hydraulic shock loads and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

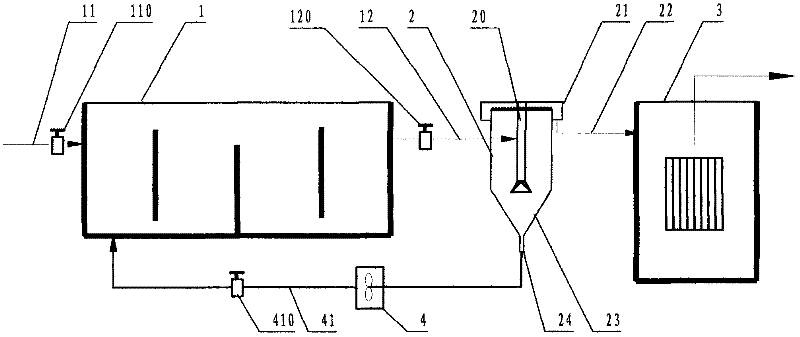

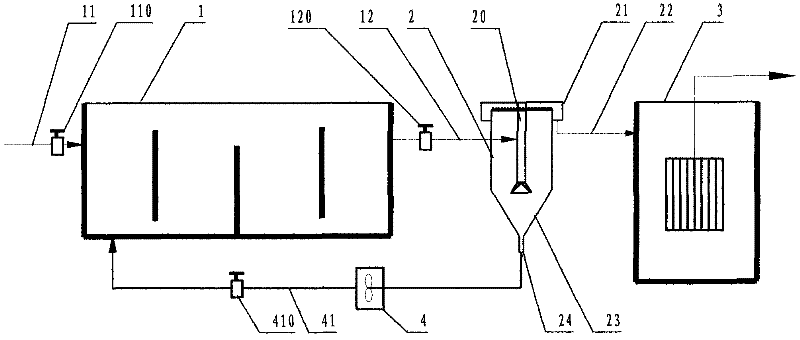

[0022] Embodiment 1: a kind of device that uses the MBR membrane pollution control of following method, be provided with biological treatment unit 1 and submerged membrane treatment unit 3, described biological treatment unit is made of anaerobic pond, anoxic pond and aerobic pond , it is characterized in that: a quick sedimentation tank 2 is arranged between the biological treatment unit and the membrane treatment unit, the quick sedimentation tank is a cylindrical tank wall, the bottom 23 is funnel-shaped, and the funnel-shaped bottom is provided with a mud collecting tank Groove 24, this mud collecting tank communicates with the anaerobic tank front end of described biological treatment unit through a sludge return device 4 that is provided with submerged propeller or air lift device; Cylinder 20, this settling cylinder is communicated with the water outlet of described biological treatment unit through water inlet pipe, is provided with overflow weir 21 at the upper mouth o...

Embodiment 2

[0023] Example 2: A device for MBR membrane pollution control consists of a biological treatment unit, a rapid sedimentation tank, and a membrane tank. Sewage first enters the biological treatment unit, the sludge concentration in the biological treatment unit is about 7000mg / L, and the hydraulic retention time is 6h. The effluent of the biological unit enters the fast sedimentation tank connected to it. The sedimentation time of the fast sedimentation tank is 20 minutes. The activated sludge with good sedimentation performance settles rapidly in the rapid sedimentation tank, and the activated sludge with poor sedimentation performance enters the membrane reaction with the effluent from the overflow weir. appliance pool. The reactor is cleaned every 3 weeks, and it has been operated for 3 months without maintenance. The membrane flux has always been maintained at 18L / m 2 h, the occurrence of membrane fouling is effectively controlled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com