Rare earth-palladium-aluminum material for magnetic refrigeration and its preparation method and use

A technology of magnetic refrigeration materials and aluminum materials, which can be used in magnetic materials, heat exchange materials, chemical instruments and methods, etc., and can solve problems such as commercial application limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] According to a first embodiment of the present invention, there is provided a method for preparing ErPdAl with a hexagonal crystal structure, comprising the following steps:

[0053] Step 1): weighing materials according to ErPdAl chemical formula (ie atomic ratio), mixing commercially available rare earth metal Er with a purity of 99.9% with Pd and Al raw materials, wherein Er is added in excess of 2% (atomic percentage);

[0054] Step 2): Put the raw materials configured in step 1) into the electric arc furnace to vacuumize, when the vacuum degree reaches 3×10 -3 Pa, after cleaning twice with high-purity argon with a purity of 99.999%, repeated turning and melting for five times under the protection of high-purity argon at 1 atmosphere, the melting temperature is between 1200°C-1500°C, after melting The furnace was cooled to room temperature and the product was obtained.

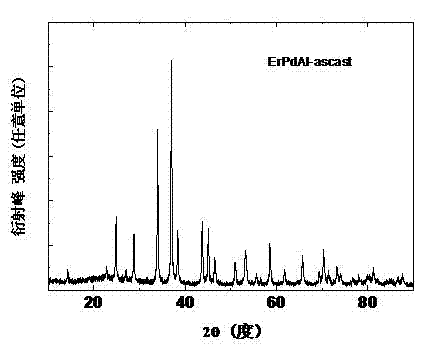

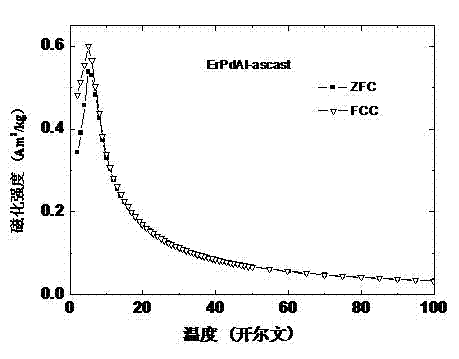

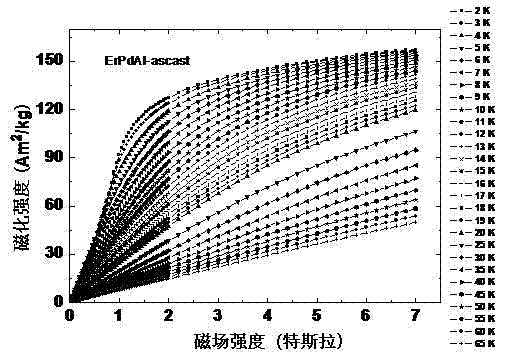

[0055] Utilize X-ray diffractometer to measure the room temperature X-ray diffraction spectrum ...

Embodiment 2

[0062] According to a second embodiment of the present invention, there is provided a method for preparing ErPdAl with a hexagonal crystal structure, comprising the following steps:

[0063] Step 1): weighing materials according to ErPdAl chemical formula (ie atomic ratio), mixing commercially available rare earth metal Er with a purity of 99.9% with Pd and Al raw materials, wherein Er is added in excess of 2% (atomic percentage);

[0064] Step 2): Put the raw materials configured in step 1) into the electric arc furnace to vacuumize, when the vacuum degree reaches 3×10 -3 Pa, after cleaning twice with high-purity argon with a purity of 99.999%, repeated turning and melting for five times under the protection of high-purity argon at 1 atmosphere, the melting temperature is between 1200°C-1500°C, after melting Cool the furnace to room temperature;

[0065] Step 3): Cool the cast alloy in a copper crucible, wrap the cast alloy with molybdenum foil, and seal it in a vacuum of 5×...

Embodiment 3

[0072] According to a third embodiment of the present invention, there is provided a method for preparing ErPdAl with an orthorhombic crystal structure, comprising the following steps:

[0073] Step 1): weighing materials according to ErPdAl chemical formula (ie atomic ratio), mixing commercially available rare earth metal Er with a purity of 99.9% with Pd and Al raw materials, wherein Er is added in excess of 2% (atomic percentage);

[0074] Step 2): Put the raw materials configured in step 1) into the electric arc furnace to vacuumize, when the vacuum degree reaches 3×10 -3 Pa, after cleaning twice with high-purity argon with a purity of 99.999%, repeated turning and melting for five times under the protection of high-purity argon at 1 atmosphere, the melting temperature is between 1200°C-1500°C, after melting Cool the furnace to room temperature;

[0075] Step 3): Cool the cast alloy in a copper crucible, wrap the cast alloy with molybdenum foil, and seal it in a vacuum of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com