Rare earth-gallium material for magnetic refrigeration and preparation method thereof

A magnetic refrigeration and rare earth technology, applied in the field of rare earth-gallium materials and their preparation, can solve the problems of limited commercial application, low magnetic refrigeration capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

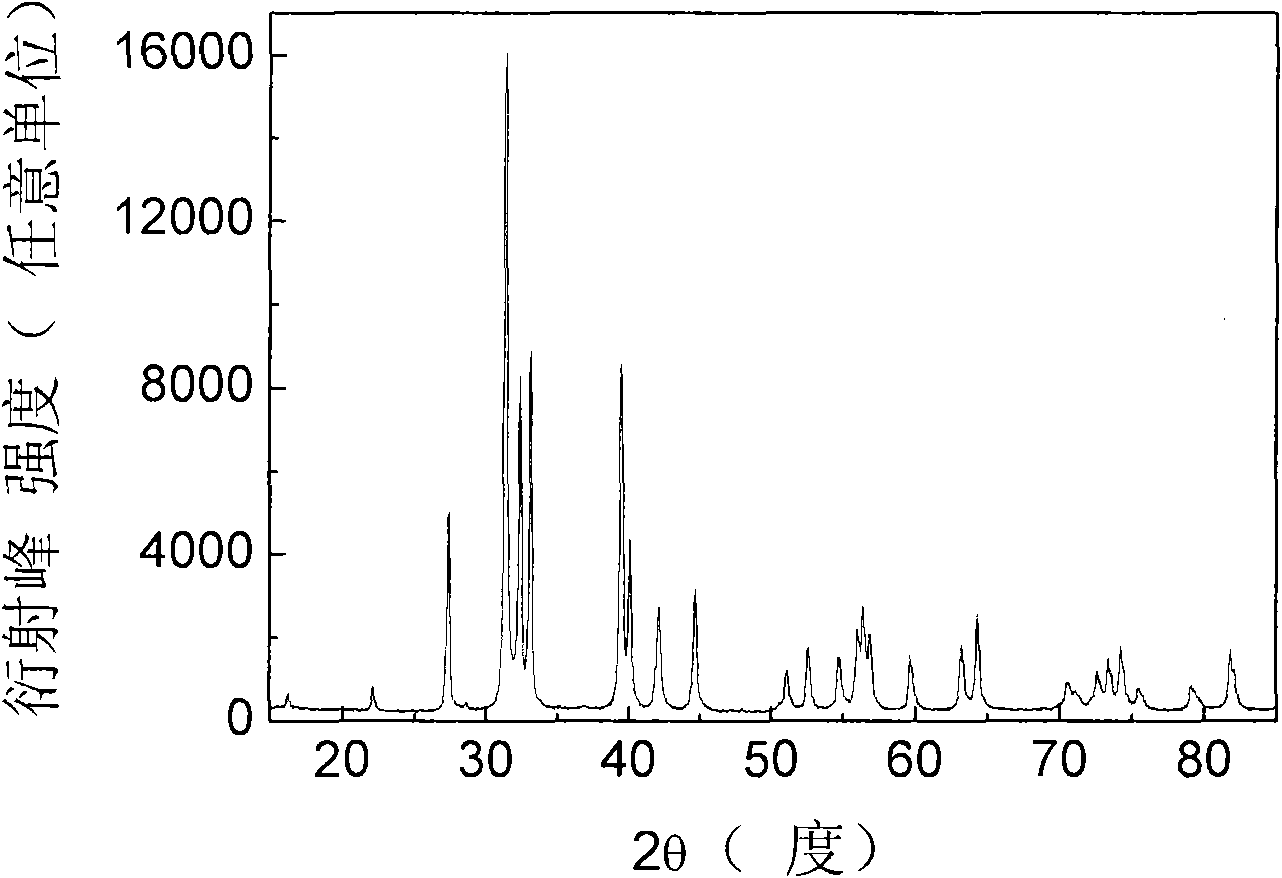

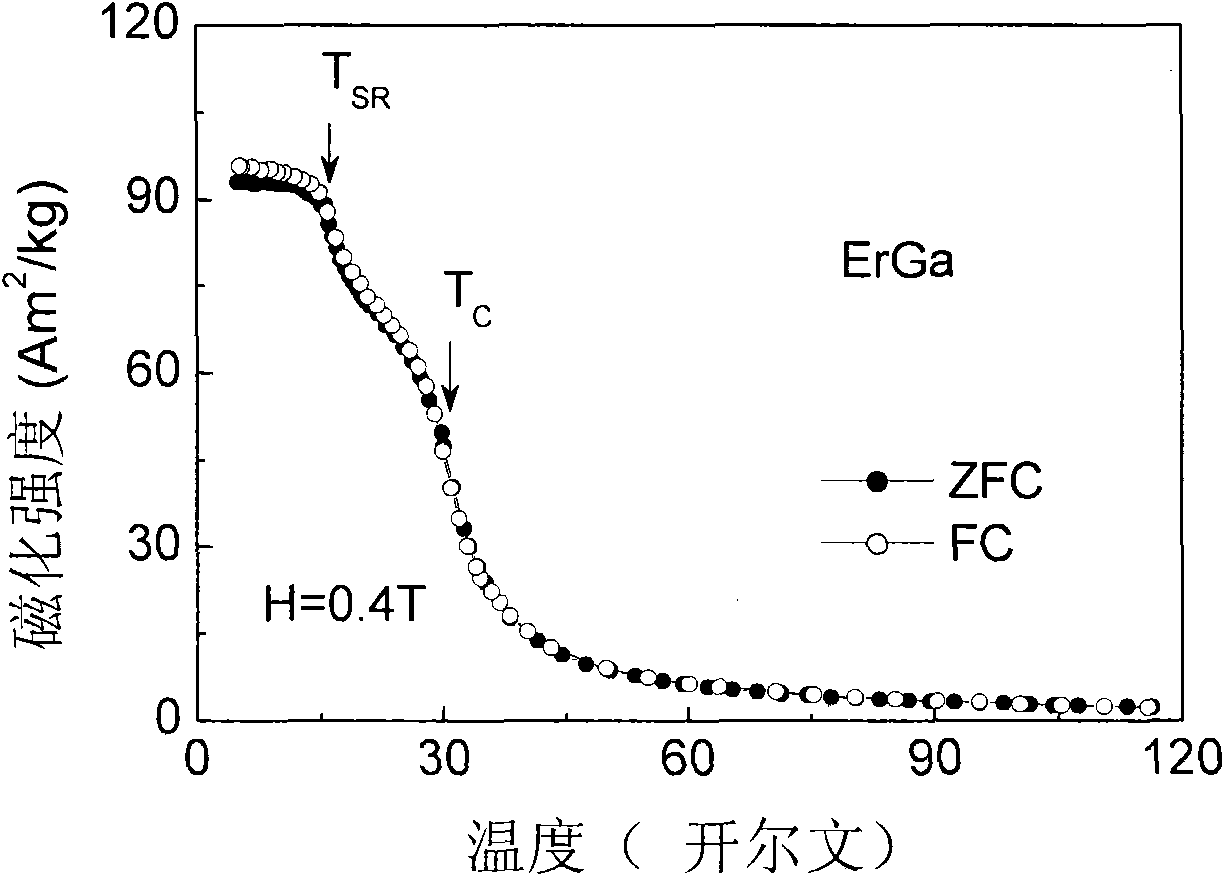

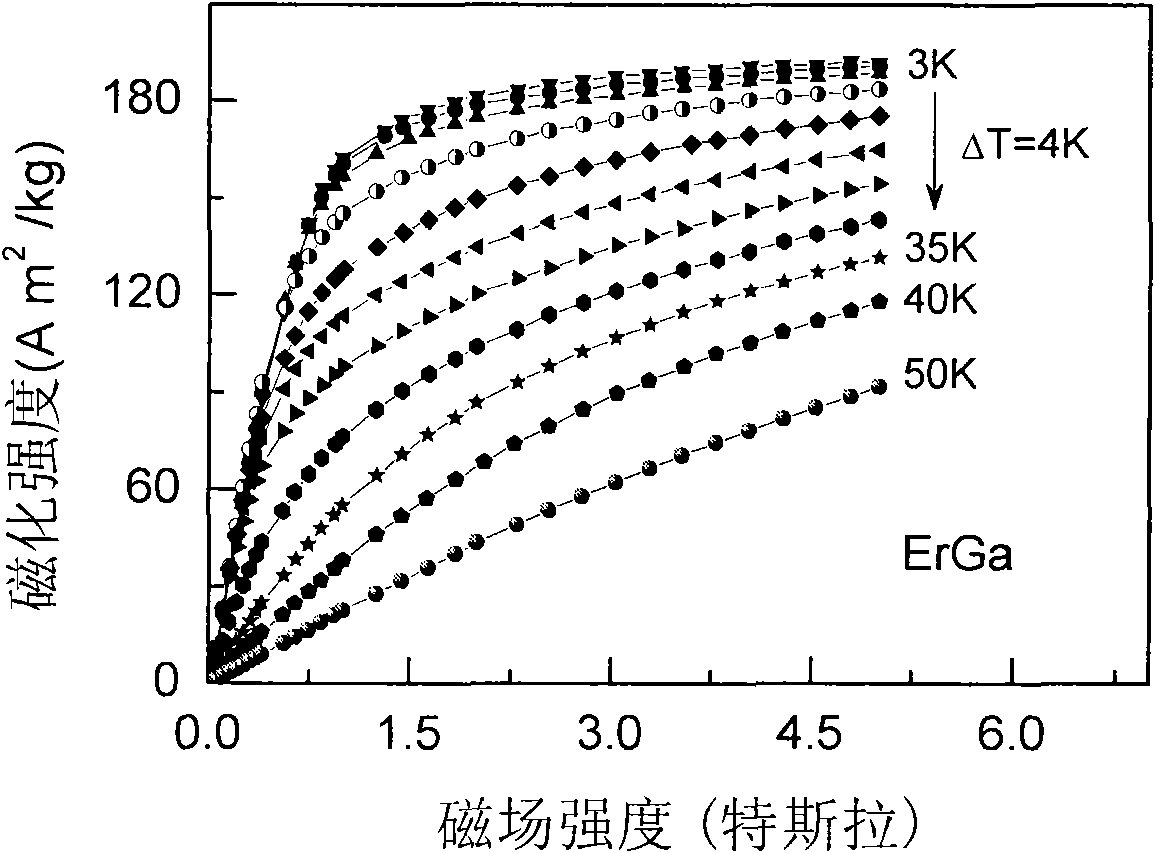

[0032] According to a first embodiment of the present invention, a method for preparing ErGa is provided, comprising the following steps:

[0033] Step 1): weighing materials according to ErGa chemical formula (ie, atomic ratio), mixing commercially available rare earth metal Er with a purity higher than 99.9% and Ga raw materials, wherein Er is added in excess of 2% (atomic percentage);

[0034] Step 2): Put the prepared raw materials in step 1) into the electric arc furnace or induction heating furnace for vacuuming, when the vacuum degree reaches 2×10 -3 -3×10 -3 Pa, after cleaning with high-purity argon with a purity of 99.999% for 1-2 times, under the protection of high-purity argon at 1 atmosphere, repeatedly turn over and melt for 3-5 times, and the melting temperature is between 1500°C and 1700°C;

[0035] Step 3): Cool the cast alloy in a copper crucible, wrap the cast alloy with molybdenum foil, and seal it in a vacuum of 5×10 -5 In a Pa quartz tube, it was anneale...

Embodiment 2

[0044] According to a second embodiment of the present invention, a method for preparing HoGa is provided, comprising the following steps:

[0045] Step 1): weighing materials according to the HoGa chemical formula (ie atomic ratio), mixing commercially available rare earth metal Ho with a purity higher than 99.9% and Ga raw materials, wherein Ho is added in excess of 2% (atomic percentage);

[0046] Step 2): Put the prepared raw materials in step 1) into the electric arc furnace or induction heating furnace for vacuuming, when the vacuum degree reaches 2×10 -3 -3×10 -3 Pa, after cleaning with high-purity argon with a purity of 99.999% for 1-2 times, under the protection of high-purity argon at 1 atmosphere, turn and melt repeatedly for 3 times, and the melting temperature is between 1500°C and 1700°C;

[0047] Step 3): Cool the cast alloy in a copper crucible, wrap the cast alloy with molybdenum foil, and seal it in a vacuum of 5×10 -5 In a Pa quartz tube, it was annealed a...

Embodiment 3

[0055] According to a third embodiment of the present invention, a method for preparing DyGa is provided, comprising the following steps:

[0056] Step 1): weighing materials according to the chemical formula of DyGa (ie atomic ratio), mixing commercially available rare earth metal Dy with a purity higher than 99.9% and Ga raw materials, wherein Dy is excessively added by 4% (atomic percentage);

[0057] Step 2) and step 3) are identical with embodiment 1.

[0058] The room temperature X-ray diffraction spectrum line of this embodiment compound is as follows Figure 11 As shown, the results show that HoGa forms a single-phase CrB-type orthorhombic crystal structure, the space group is Cmcm, and its lattice parameter

[0059] The thermomagnetic (M-T) curve of present embodiment compound is as follows Figure 12 As shown, the Curie temperature T of DyGa can be determined from the M-T curve C for 115K. The compound of this example is in the T C The nearby magnetic entr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com