Locomotive braking resistance tape and preparation method thereof

A technology of brake resistors and locomotives, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of unsuitable resistance bands, high cost, and high price, and achieve the effects of improving product quality, ensuring purity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

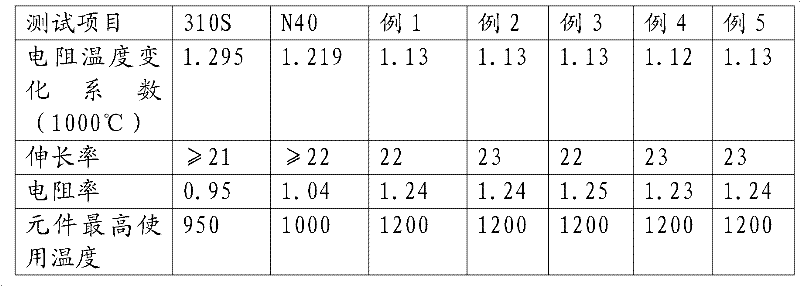

Examples

Embodiment 1

[0009] The locomotive braking resistance belt of this embodiment includes the weight percent content of each main component: chromium: 13.5%, aluminum: 4.5%, titanium: 0.35%, carbon: ≤0.04%, rare earth: 0.05%, iron: the balance .

Embodiment 2

[0011] The locomotive braking resistance belt of this embodiment includes the weight percent content of each main component: chromium: 14%, aluminum: 4.0%, titanium: 0.30%, carbon: ≤0.03%, rare earth: 0.07%, iron: balance .

Embodiment 3

[0013] The locomotive braking resistance belt of this embodiment includes the weight percent content of each main component: chromium: 14.5%, aluminum: 3.5%, titanium: 0.25%, carbon: ≤0.02%, rare earth: 0.10%, iron: the balance .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com