Pulse plasma thruster with ceramic nozzles on the side wall

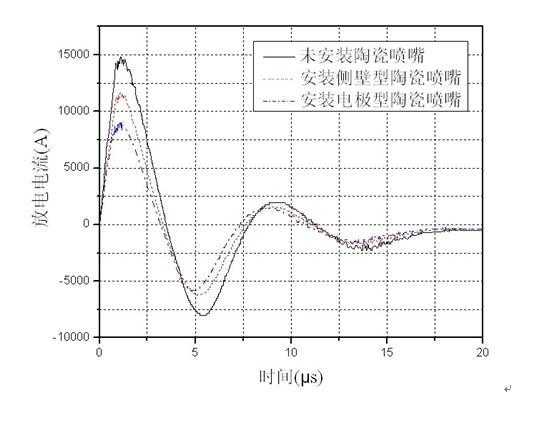

A technology of pulsed plasma and ceramic nozzles, applied in the direction of utilizing plasma, reverse thrust devices, mechanical equipment, etc., can solve the problems of reducing discharge current, reducing electromagnetic acceleration performance and thrust, increasing the discharge resistance of the main circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

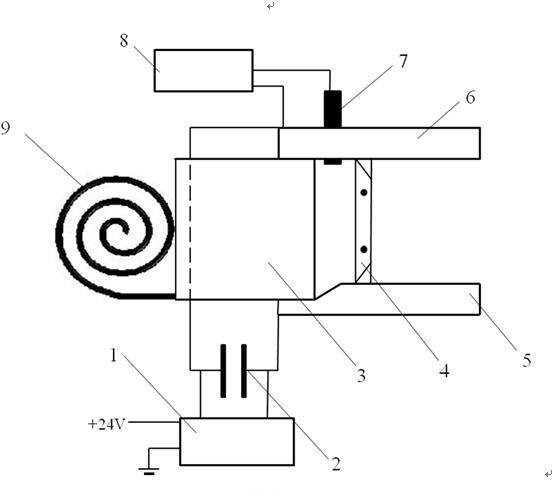

[0019] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

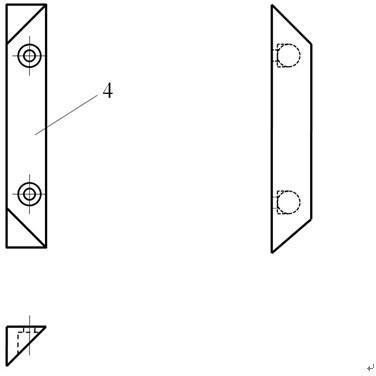

[0020] Such as figure 1 As shown, this embodiment includes: a high voltage power supply 1, an energy storage capacitor 2, a propellant 3, a side wall type ceramic nozzle 4, an anode 5, a cathode 6, a semiconductor spark plug 7, an ignition control circuit board 8, and a feed spring 9. The high-voltage power supply 1 is connected to the energy storage capacitor 2 through wires, charges the capacitor and stores the pulse discharge energy in the energy storage capacitor 2; the propellant 3 is fixed horizontally by the feed spring 9 and the boss of the anode 5, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cut corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com