Air-conditioning and refrigeration system using liquid metal heat dissipation

A liquid metal, air-conditioning refrigeration technology, applied in the direction of refrigerators, refrigeration and liquefaction, indirect heat exchangers, etc., can solve the problems of increased power consumption of air conditioners, small temperature difference in heat transfer of air conditioners, increased power consumption and noise, etc. , to achieve obvious environmental protection, low energy consumption, and less moving parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

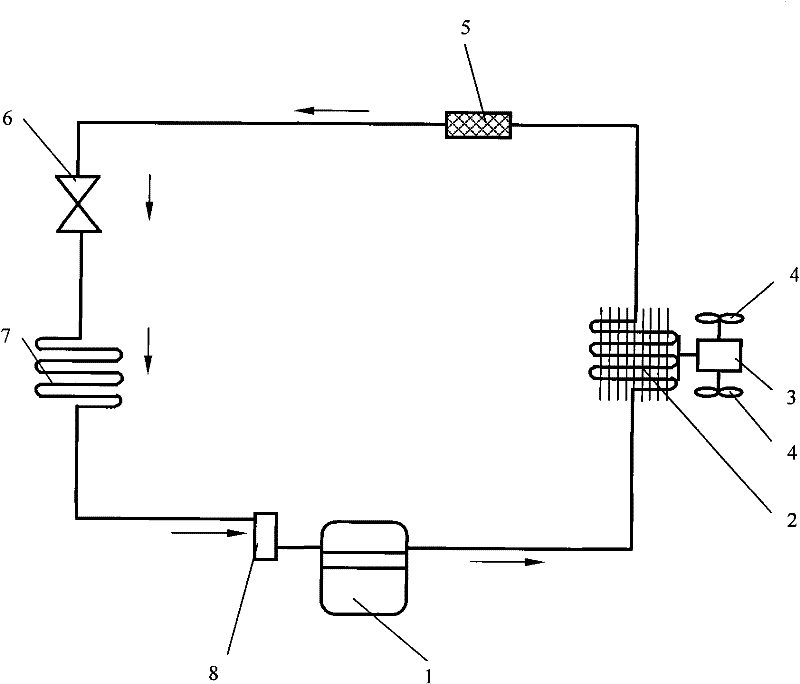

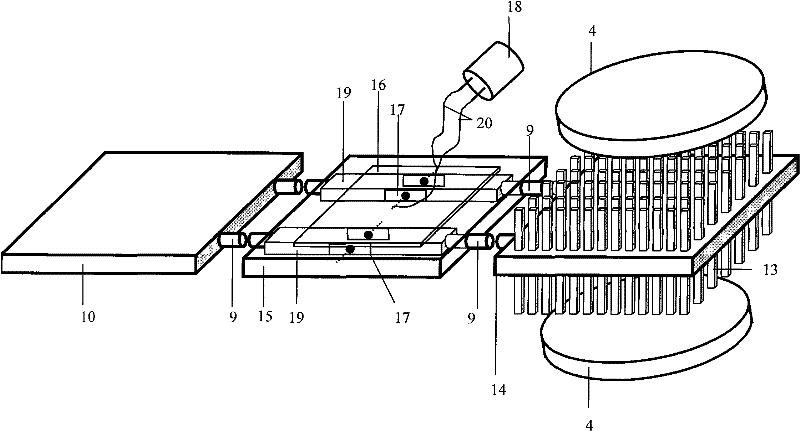

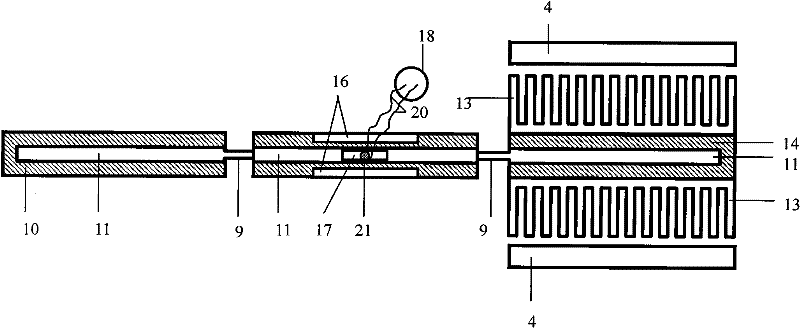

[0036] figure 1 It is a schematic diagram of the circulation of a new refrigeration system based on liquid metal heat dissipation provided by the present invention, and it is also an embodiment of the present invention; figure 2 It is a structural schematic diagram of the liquid metal radiator provided by the present invention; image 3 is a schematic cross-sectional view of the liquid metal radiator provided by the present invention; Figure 4 It is a schematic diagram of the flow channel structure in the heat exhaust plate provided by the present invention. As can be seen from the figure, the air-conditioning and refrigeration system using liquid metal heat dissipation provided by the present invention includes a compressor 1, a condenser 2, a dry filter 5, an expansion valve 6, an evaporator 7 and A liquid separator 8; a refrig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com