Preparation method of organic solar cell and organic solar cell prepared therefrom

A solar cell and organic technology, applied in the field of solar cells, achieves the effects of low cost, favorable promotion and application, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

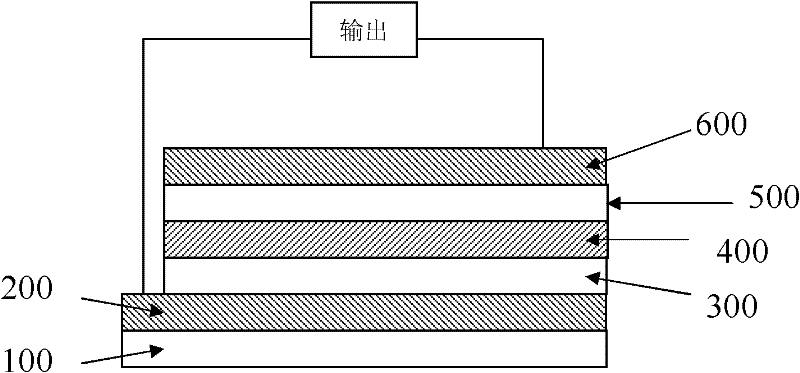

preparation example Construction

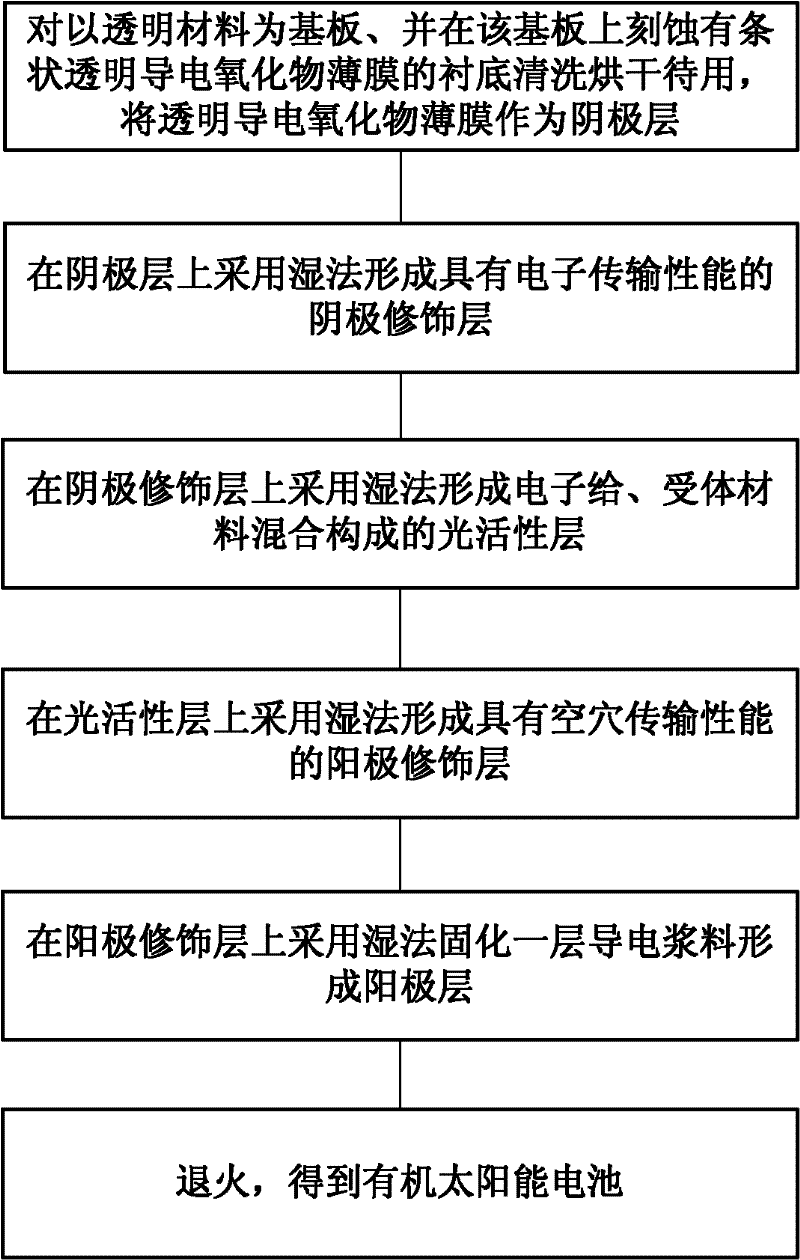

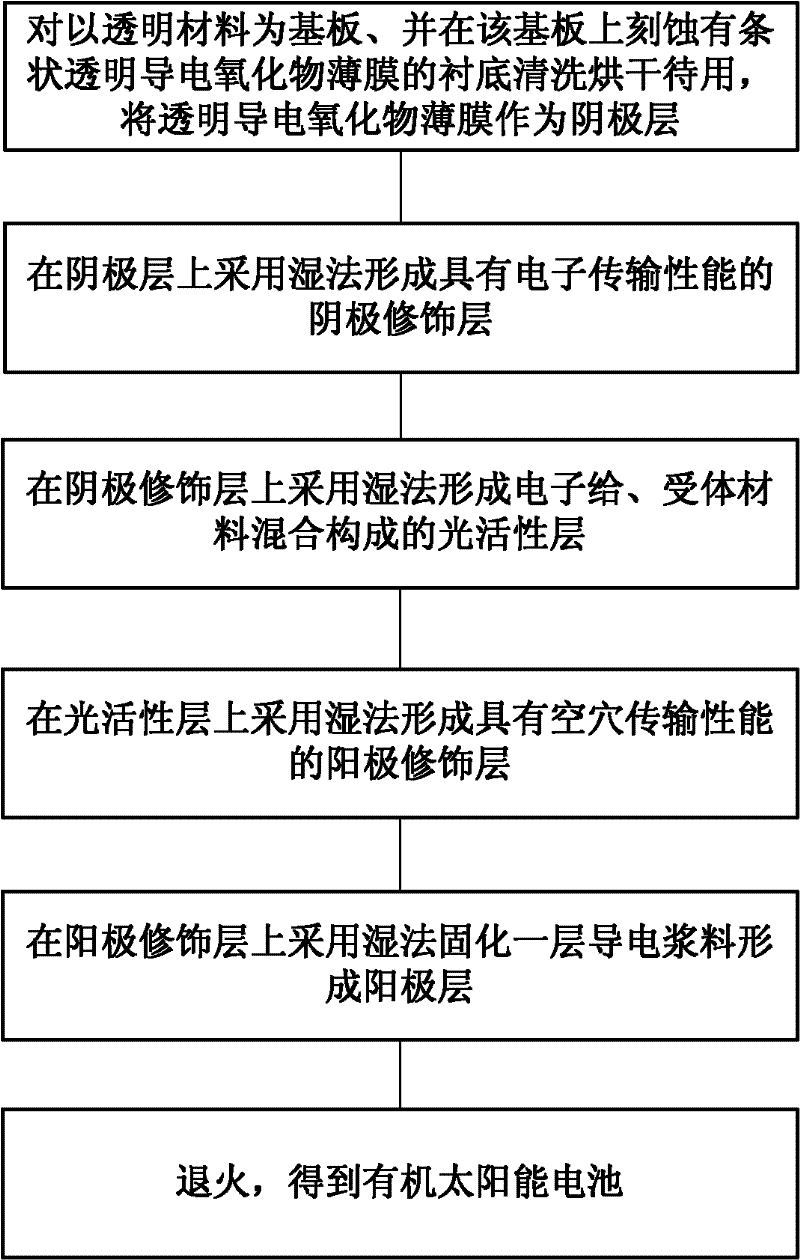

[0043] figure 2 It is a flowchart of the preparation method of the organic solar cell of the present invention. Such as figure 2 As shown, in the preparation method of the present invention, all adopt the wet method to prepare each layer of the organic solar cell:

[0044] Clean and dry the substrate with a transparent material as the substrate and etched a strip-shaped transparent conductive oxide film on the substrate, and use the transparent conductive oxide film on the substrate as the cathode layer; in the above The transparent conductive oxide film is prepared by wet methods such as sol-gel method, spin coating method, screen printing method, inkjet printing method, spraying method, etc. to form a cathode modification layer with electron transport properties;

[0045] Then, on the cathode modification layer prepared in the previous step, the electron donor material and the electron acceptor material are deposited by wet methods such as sol-gel method, spin coating me...

Embodiment 1

[0049] (1) On the glass substrate, utilize the sol-gel method to prepare the ITO transparent conductive film that thickness is 80nm, and etch into the thin strip shape with certain width, clean and dry stand-by;

[0050] (2) The ZnO nanoparticles prepared by the sol-gel method are dispersed in chlorobenzene, and the concentration is 50mg / mL, and then spin-coated on the ITO transparent conductive film, and the speed of the homogenizer is 4500rpm (rev / min), uniform The glue time is 30s, forming a layer of ZnO with a thickness of 20nm, and heating at 180°C for 35min to solidify, then cooling;

[0051] (3) On the ZnO layer, add dropwise the chlorobenzene solution containing P3HT and PCBM with a mass ratio of 4: 1, uniformly mixed, and a total concentration of 15 mg / mL. Obtain a photoactive layer with a thickness of 60nm, place it in a glove box, heat at 120°C for 15min to solidify, and cool;

[0052] (4) Spin-coat a PEDOT:PSS layer on the photoactive layer, control the speed of t...

Embodiment 2

[0056] (1) On the silicon substrate, the AZO transparent conductive film with a thickness of 100nm is prepared by the sol-gel method, and etched into thin strips with a certain width, cleaned and dried for use;

[0057] (2) Prepare a layer of TiO with a thickness of 40nm on the AZO transparent conductive film by sol-gel method 2 , and heated at 200°C for 20 minutes to solidify, then cooled;

[0058] (3) on TiO 2 On the layer, a chlorobenzene solution containing P3HT and PCBM with a mass ratio of 2:1, uniformly mixed, and a total concentration of 18 mg / mL was added dropwise, and a photoactive layer with a thickness of 200 nm was prepared by inkjet printing and placed in a glove box. Heating at 100°C for 25 minutes to solidify, then cooling;

[0059] (4) Disperse NiO nanoparticles in dichloromethane, print a layer of NiO with a thickness of 60nm on the active layer by screen printing, heat at 50°C for 15min to solidify, and cool;

[0060] (5) Utilize spraying method to form o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap