Cooling water ring device for injection mold

A cooling water and body technology, applied in the field of molds, can solve the problems of inability to control temperature, prevent strain and shrinkage, etc., and achieve the effects of ensuring product size requirements, improving production efficiency, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

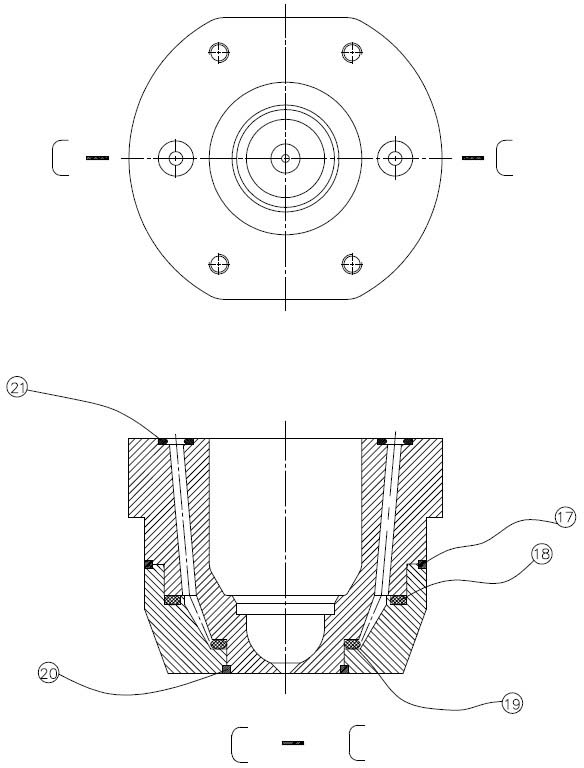

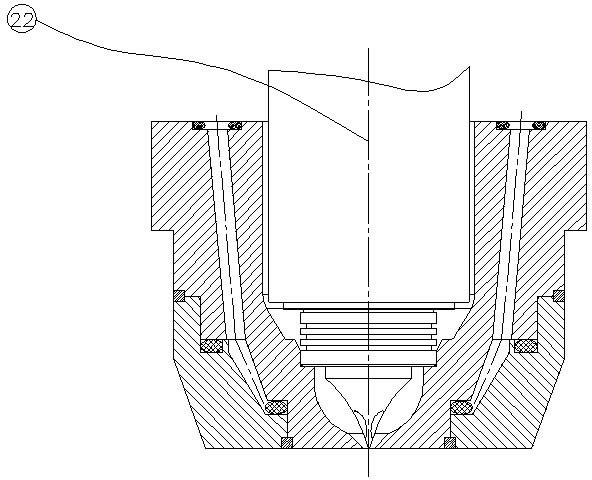

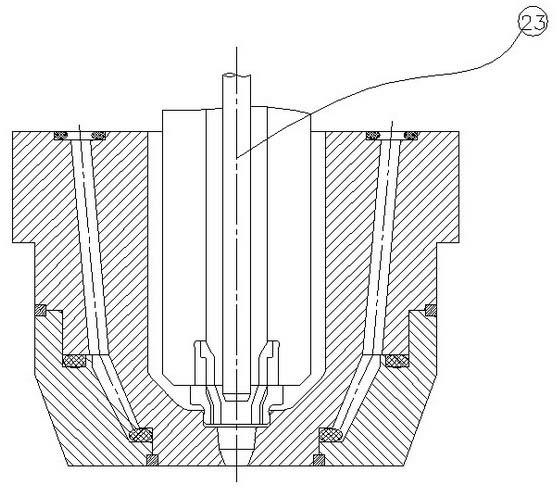

[0019] Specific embodiments of the invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0020] Put the internal pressure sealing rubber ring 19 on the sealing column 5 of the internal pressure rubber ring, and cooperate with it in clearance. Put the external pressure sealing rubber ring 18 into the groove 14 of the external pressure sealing rubber ring to cooperate with it. The cooling water ring body 12 is screwed to the fixed hot nozzle body 9, and after tightening, the internal pressure sealing rubber ring 19 and the internal pressure rubber ring sealing column 5 are in surface contact to play the role of sealing water. The external pressure sealing rubber ring 18 is in contact with the external pressure sealing rubber ring groove 14 to play the role of sealing water.

[0021] Weld the connection between the fixed hot nozzle body 9 and the cooling water ring body 12 . All-round welds 17 and all-round welds 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com