Dual-interlayer symmetrical multi-pyramid configuration three-dimensional integrally-braid lattice composite material and preparation method thereof

A technology of integral weaving and composite materials, applied in the field of textile composite materials and their preparation, double-sandwich symmetrical polygonal pyramid configuration three-dimensional integral weaving lattice composite materials and their preparation fields, can solve the lack of preparation technology of lattice composite materials and composite materials. The structure cannot be used, the lattice core lacks supporting points, etc., to avoid degumming and delamination, excellent overall performance, and height increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

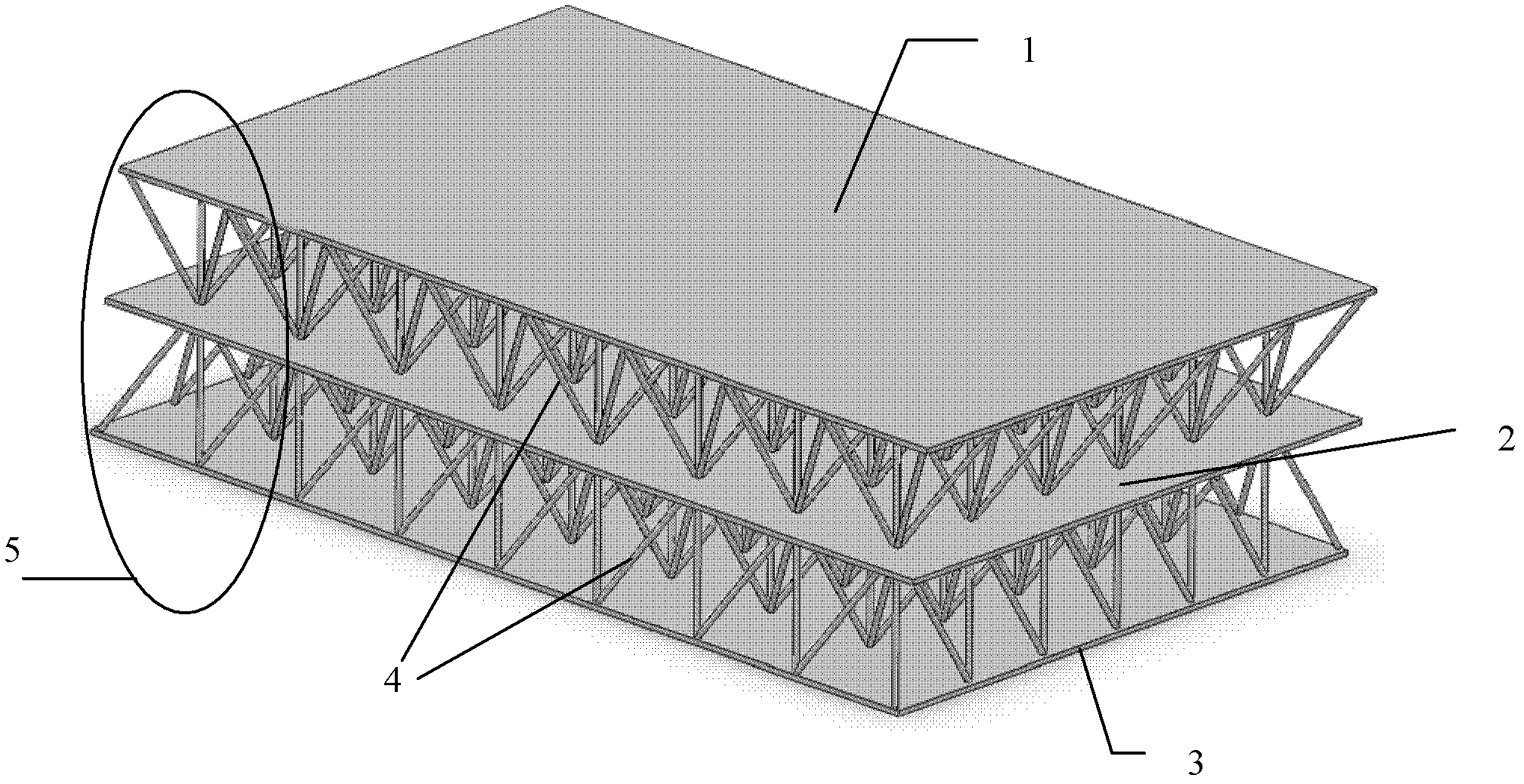

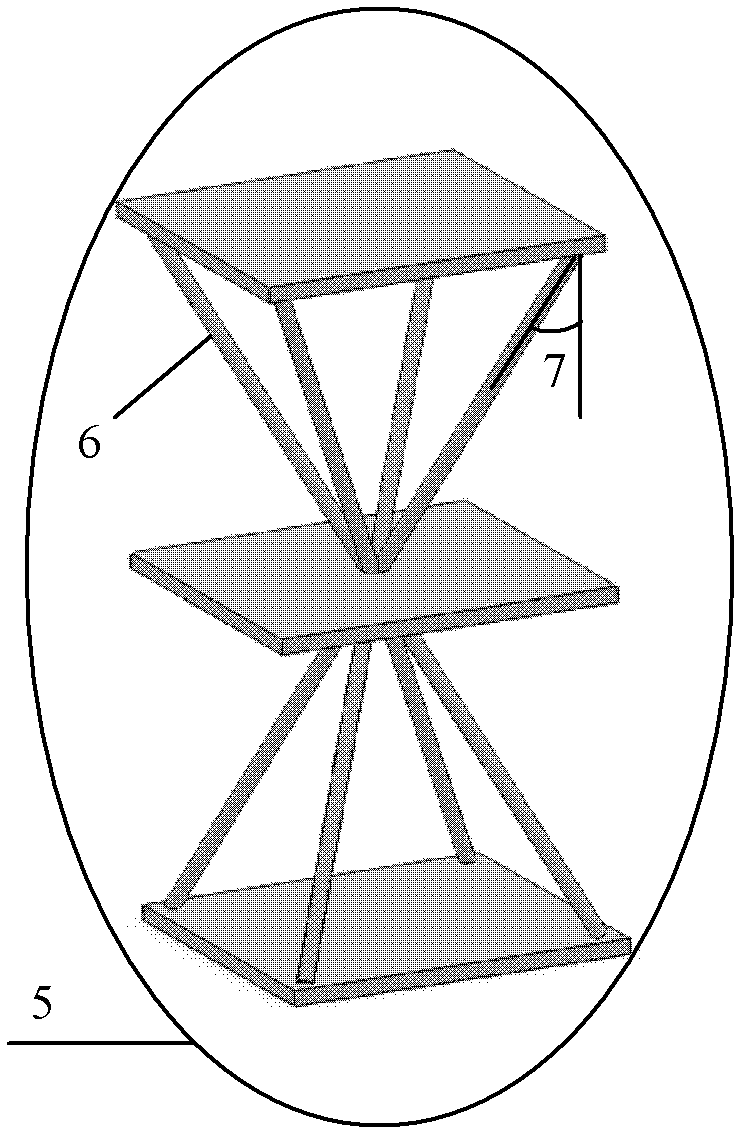

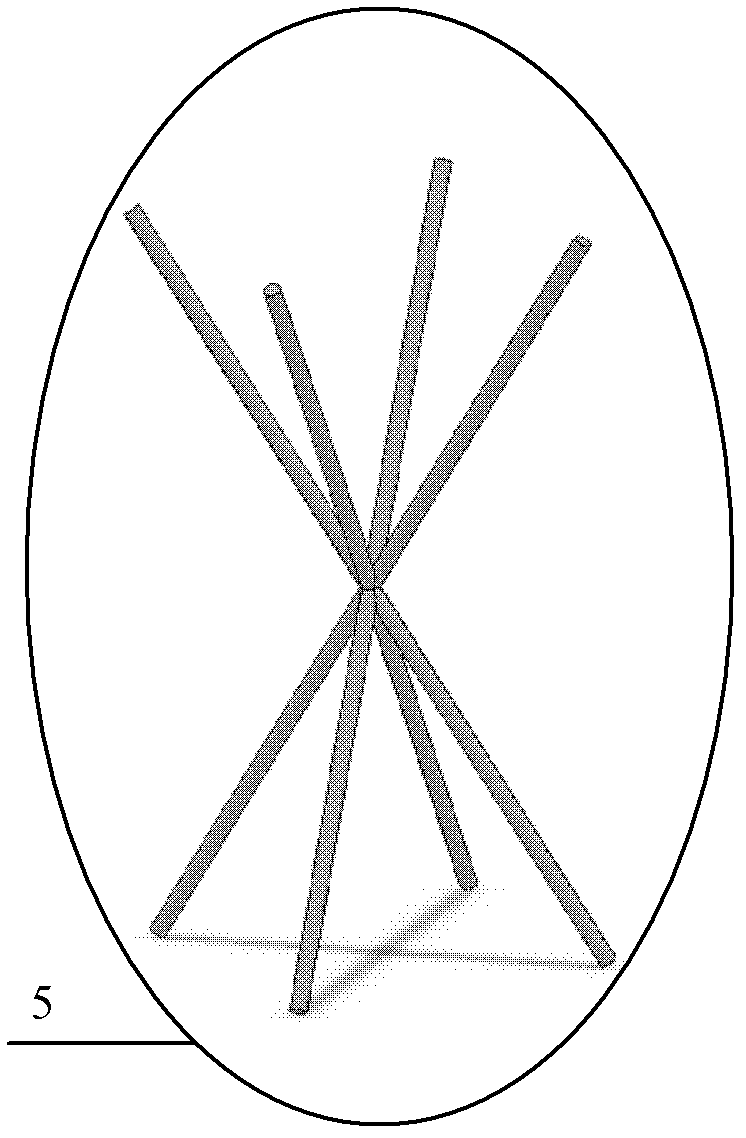

[0032] figure 1 A schematic diagram of the structure of a double sandwich symmetrical quadrangular pyramid configuration three-dimensional integral braided lattice composite material provided by the present invention, which consists of an upper panel layer 1, a middle panel layer 2, a lower panel layer 3, and upper, middle, middle and lower panel layers The middle lattice core layer 4 is composed of, and it is characterized in that: the upper middle panel layer and the middle and lower panel layer form a double sandwich structure, and the lattice core layer is composed of symmetrical quadrangular pyramid configuration unit cells with interlinked pores periodically arranged The space network truss structure composed of 5, and the lattice core layer and the upper, middle and lower panel layers are woven, interspersed, wound and sewn into a whole according to the design r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com