MEMS (micro electro mechanical system) apparatus and forming method thereof

A device and graphics technology, applied in the field of MEMS devices and MEMS technology, can solve problems such as complex methods, uniform distribution of doping ions, limitation of implantation depth, high cost of ion implantation process, etc., to achieve simple process, and doping depth is not affected The effect of restricting and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

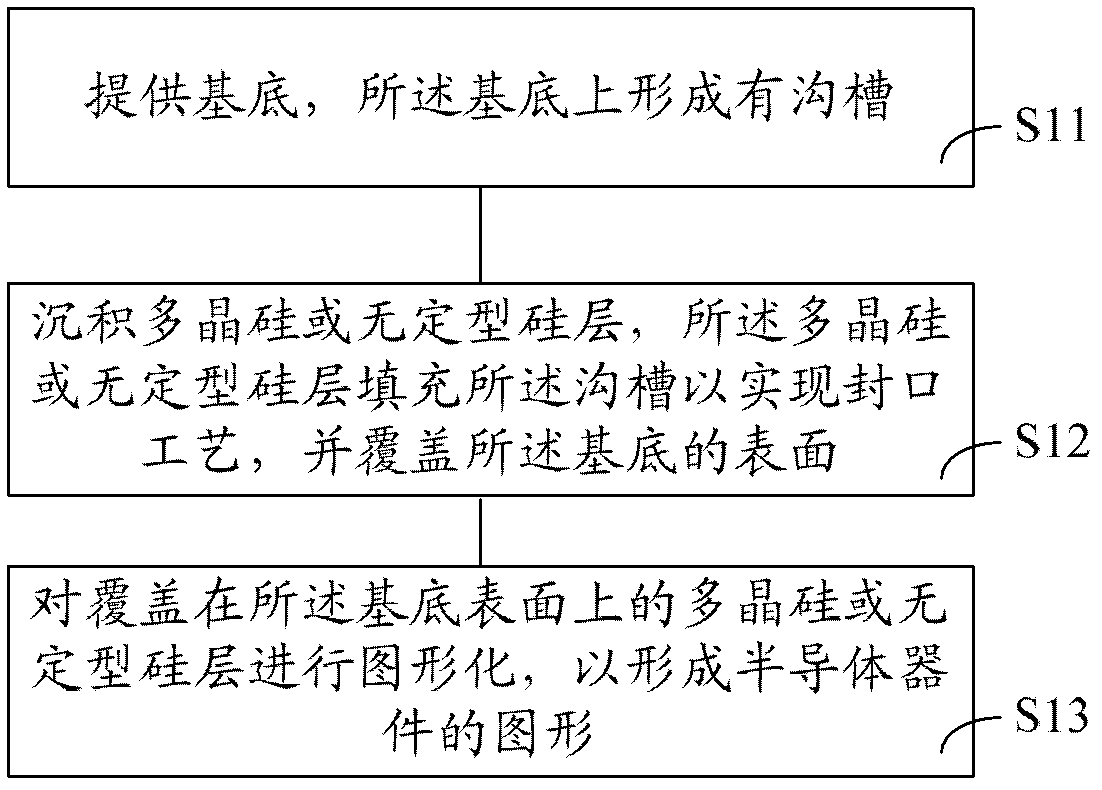

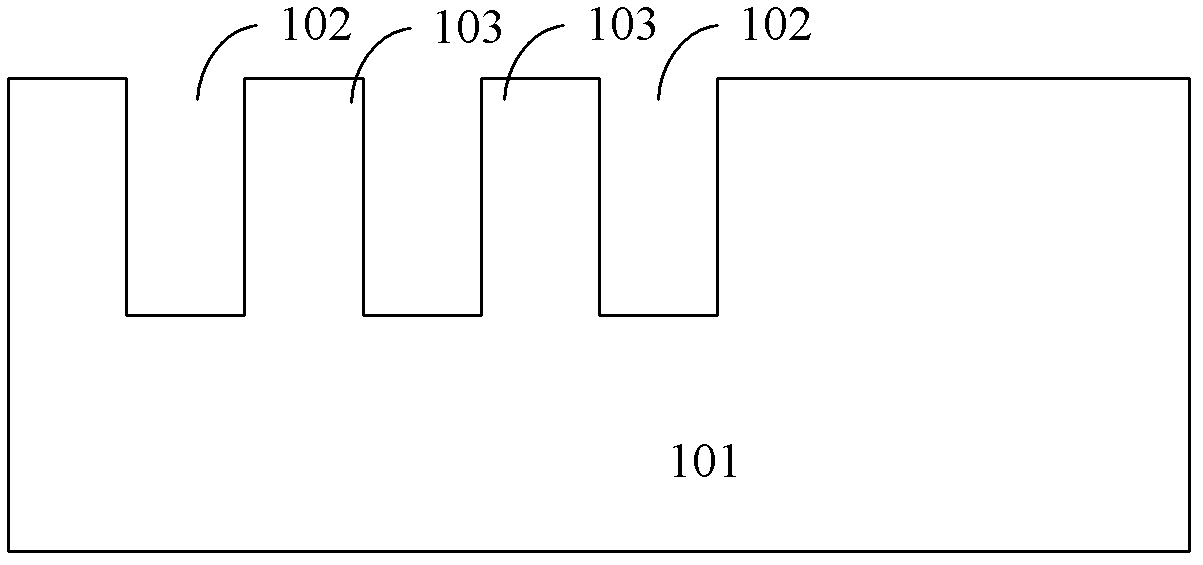

[0029] The MEMS devices in the prior art are often filled with materials such as silicon oxide, which has poor filling performance and is easily corroded by the external environment, resulting in potential reliability problems. In addition, in the prior art, the process of forming an integrated semiconductor device in a MEMS device is relatively complicated and costly.

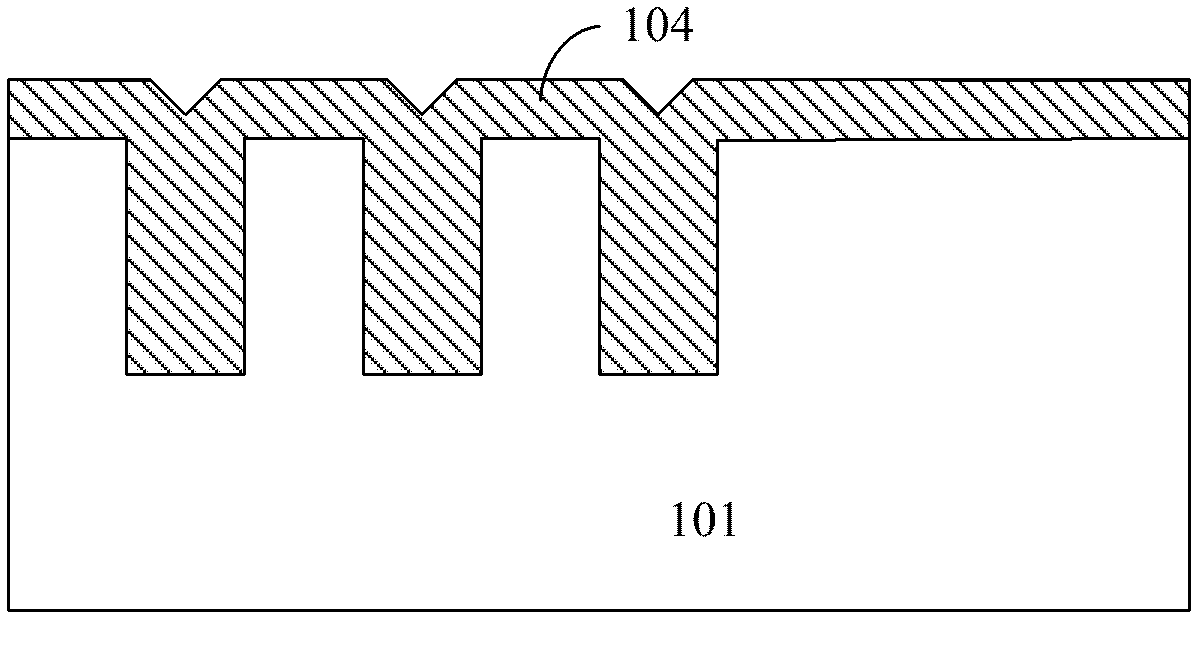

[0030] In the MEMS device and its forming method according to the embodiment of the present invention, polysilicon or amorphous silicon is used to fill the groove on the substrate, and polysilicon or amorphous silicon has good filling properties, and has a good filling property when filling a trench with a high aspect ratio. performance, and polysilicon or amorphous silicon is more stable and reliable than conventional filling materials such as silicon oxide, which is conducive to improving the reliability of MEMS devices.

[0031] Further, in the forming method of the MEMS device of the embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com