Passive escape capsule

A technology of passive rescue capsules and compartments, which is applied in the field of passive rescue capsules and rescue capsules, can solve the problems of anti-compressive and anti-seismic but not resistant to explosion shocks, large air volume and pressure, and low strength, so as to ensure heat preservation and airtight performance, The effect of dispersing the blast shock wave and high seismic and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in further detail below in conjunction with accompanying drawing:

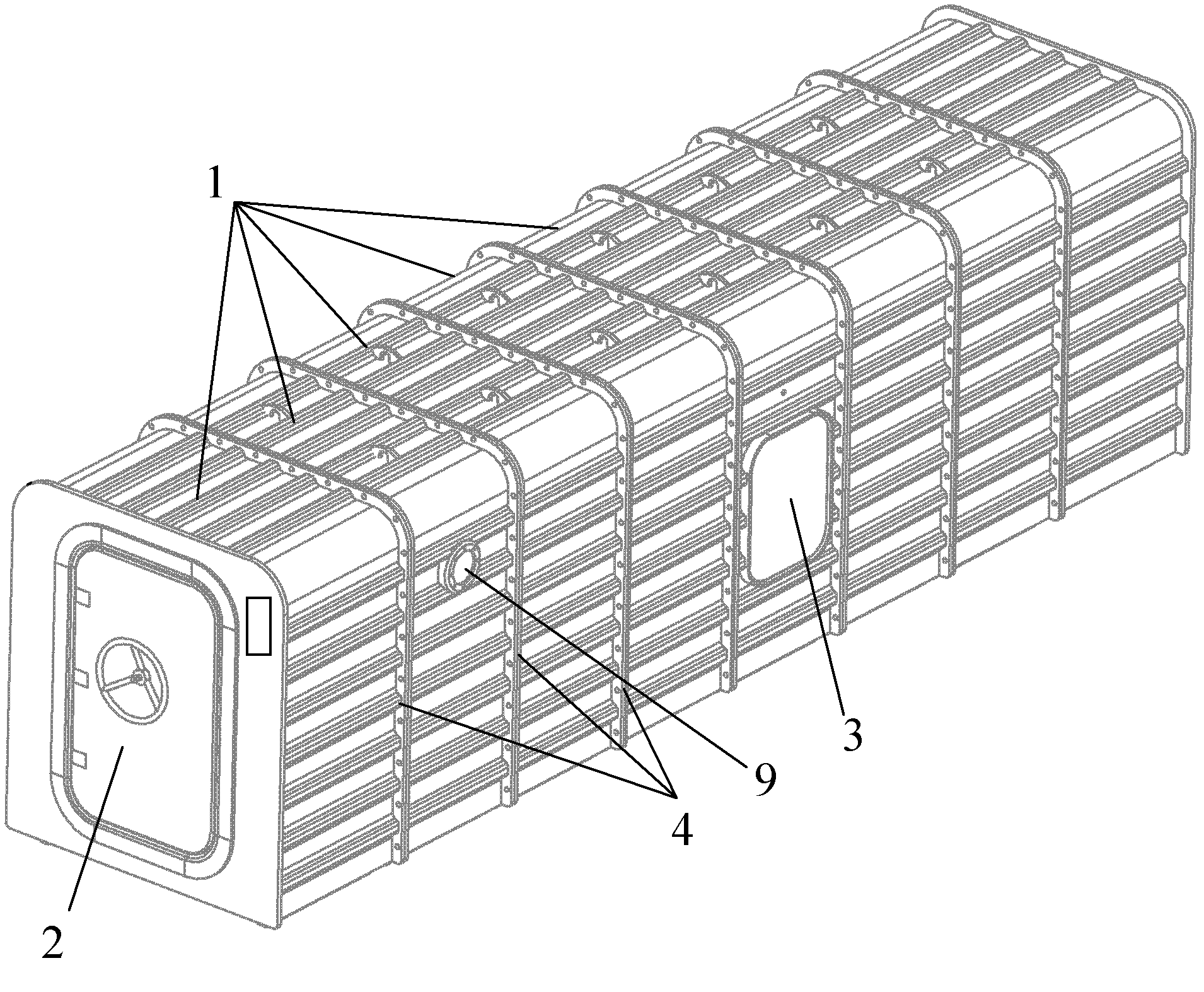

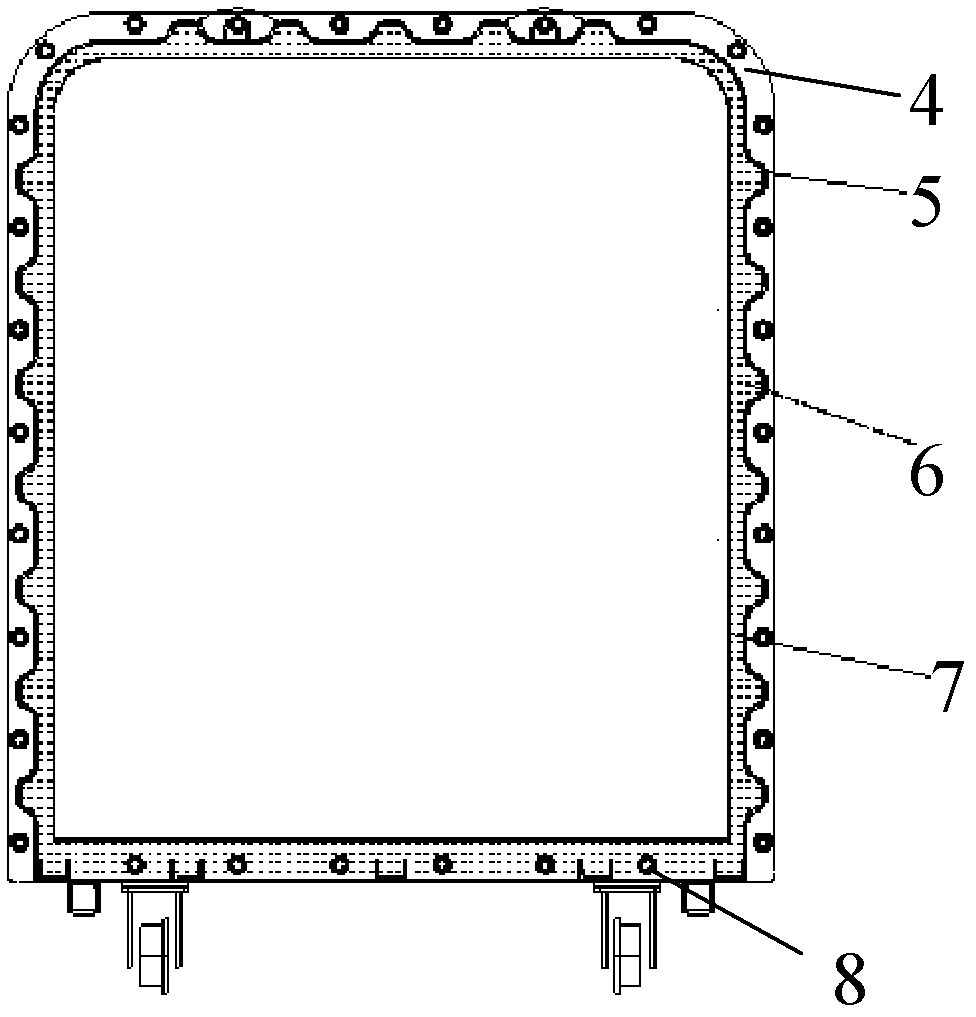

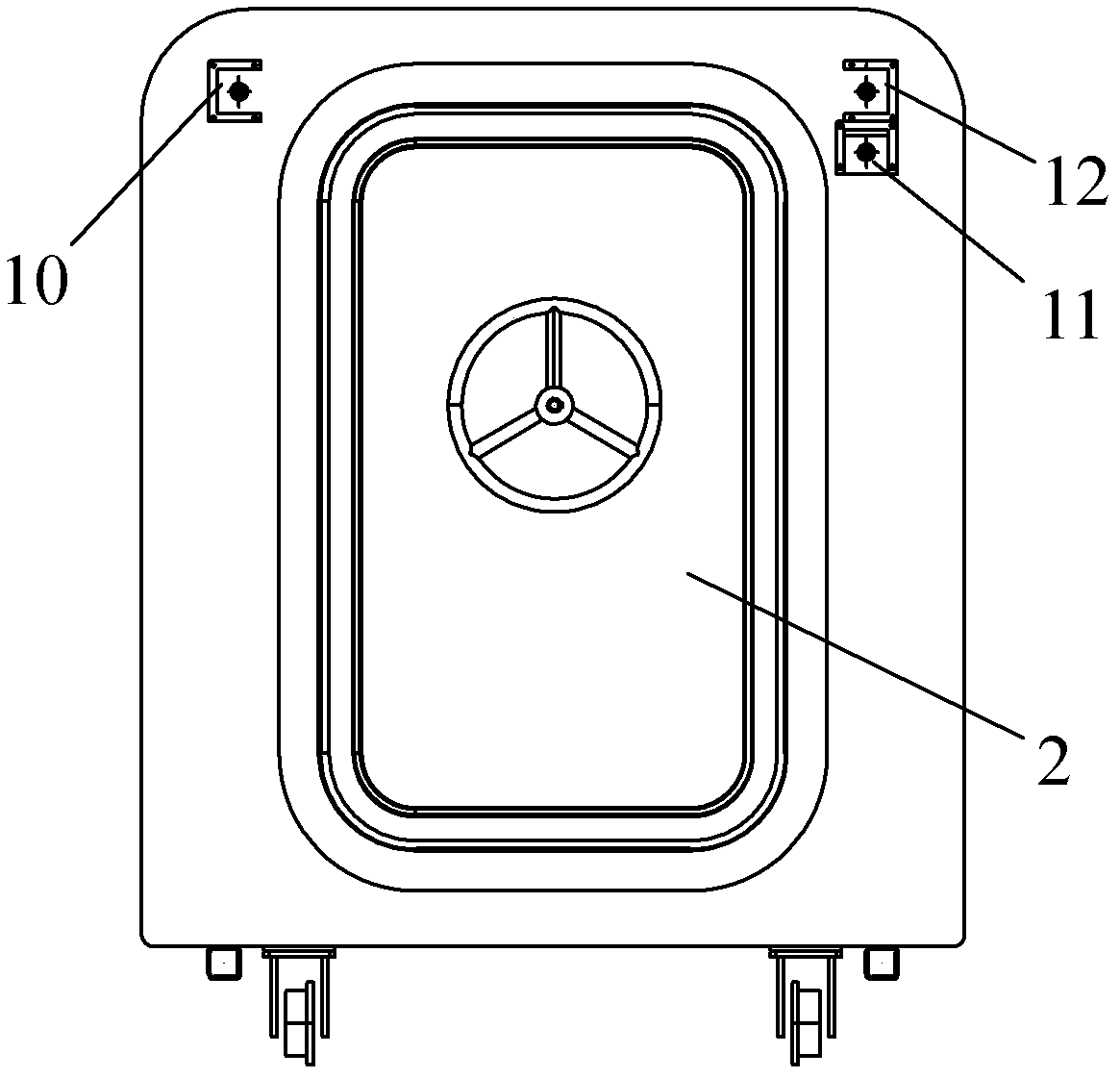

[0044] see Figure 1-3 : the passive rescue cabin of the present invention is connected by several sections 1 to form an airtight cabin, and the air purification and temperature regulation system, support system, environmental monitoring system and living facilities are equipped inside the airtight cabin; the front and rear ends of the airtight cabin There are cabin doors 2, and escape doors 3 are provided on the side of the airtight cabin; the cabin section 1 is composed of an outer skin 5, a heat insulation layer 6 and an inner skin 7 from the outside to the inside, and the two sides and the upper side of the cabin section 1 The outer skin 5 on the side is a plate with a corrugated structure, the cross section of the corrugated structure is isosceles trapezoidal, and the corrugated structures are distributed in parallel longitudinally; the heat insulation layer 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com