LCD projector light source system employing three sheet LED lamp plates

A technology of LED light source and LED light board is applied in the direction of using image reproducer, light source, point light source of projection device, etc., and can solve the problems of high price of high-power LED lamp wick, complicated optical path structure of projector, and influence on popularization and application, etc. Achieve significant practical effects, enhance utilization efficiency, and simplify the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

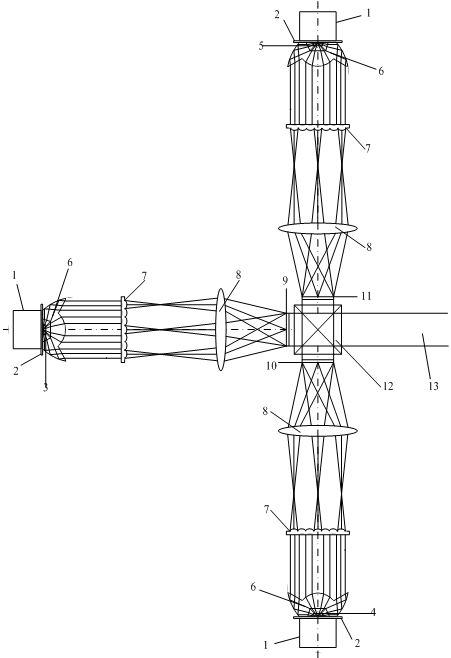

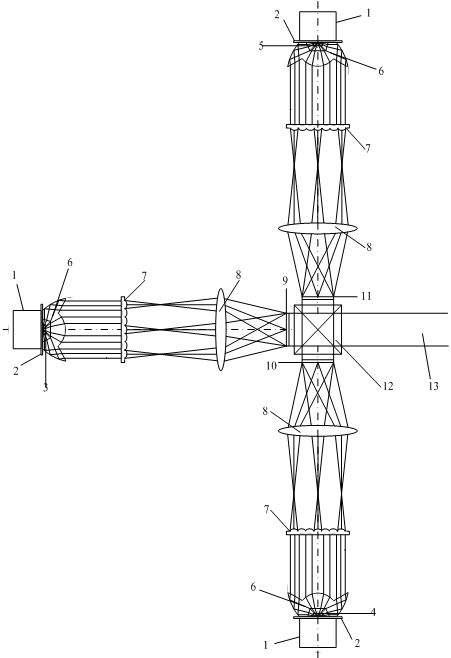

[0011] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0012] Such as figure 1 As shown, an LCD projector light source system using three LED light panels, the system includes a heat dissipation device 1, an LED light source circuit board 2, a red LED light source 3, a green LED light source 4, a blue LED light source 5, a TIR lens 6, Fly eye lens 7, Kohler lighting lens group 8, red signal LCD panel and polarizer group 9, green signal LCD panel and polarizer group 10, blue signal LCD panel and polarizer group 11, synthetic prism (X-Cube) 12 and projection objective lens 13.

[0013] The red LED light source 3, the green LED light source 4, and the blue-red LED light source 5 are installed together with the heat sink 1 and the LED light source circuit board 2 respectively. Red, green, and blue are three independent light pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com