Isolation structure of high voltage driver circuit

一种高压驱动电路、隔离结构的技术,应用在电路、电气元件、半导体器件等方向,能够解决P型结隔离区不能完全耗尽、击穿等问题,达到灵活性大、制备简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

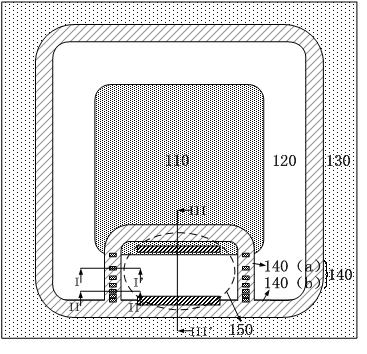

Embodiment 1

[0024] An isolation structure for a high-voltage driving circuit, comprising: a P-type substrate 1, a P-type epitaxial layer 2 is arranged on the P-type substrate 1, a low-voltage region 130 and a high-voltage region 110 are arranged on the P-type epitaxial layer 2, and the Between the low-voltage region 130 and the high-voltage region 110, there is a high-low voltage junction termination region 120, and between the high-voltage and low-voltage junction termination region 120 and the low-voltage region 130 is a first P-type junction isolation region 140a. The first P-type junction isolation The region 140a is composed of the P-type buried layer 4 and the first P-type well region 71, and a second P-type junction isolation region 140b is provided in the inner region of the first P-type junction isolation region 140a, and the second P-type junction isolation region 140b is connected to the first P-type junction isolation region 140a. The first P-type junction isolation region 140a...

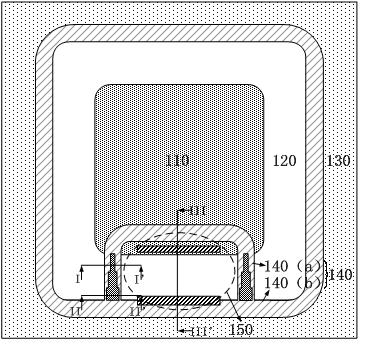

Embodiment 2

[0026] An isolation structure for a high-voltage driving circuit, comprising: a P-type substrate 1, a P-type epitaxial layer 2 is arranged on the P-type substrate 1, a low-voltage region 130 and a high-voltage region 110 are arranged on the P-type epitaxial layer 2, and the Between the low-voltage region 130 and the high-voltage region 110, there is a high-low voltage junction termination region 120, and between the high-voltage and low-voltage junction termination region 120 and the low-voltage region 130 is a first P-type junction isolation region 140a. The first P-type junction isolation The region 140a is composed of the P-type buried layer 4 and the first P-type well region 71, and a second P-type junction isolation region 140b is provided in the inner region of the first P-type junction isolation region 140a, and the second P-type junction isolation region 140b is connected to the first P-type junction isolation region 140a. The first P-type junction isolation region 140a...

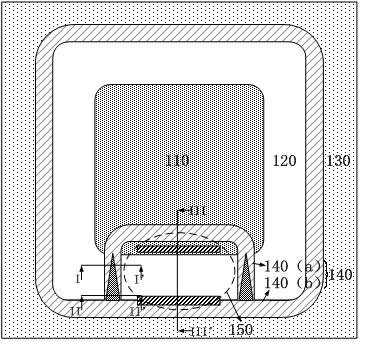

Embodiment 3

[0028] An isolation structure for a high-voltage driving circuit, comprising: a P-type substrate 1, a P-type epitaxial layer 2 is arranged on the P-type substrate 1, a low-voltage region 130 and a high-voltage region 110 are arranged on the P-type epitaxial layer 2, and the Between the low-voltage region 130 and the high-voltage region 110, there is a high-low voltage junction termination region 120, and between the high-voltage and low-voltage junction termination region 120 and the low-voltage region 130 is a first P-type junction isolation region 140a. The first P-type junction isolation The region 140a is composed of the P-type buried layer 4 and the first P-type well region 71, and a second P-type junction isolation region 140b is provided in the inner region of the first P-type junction isolation region 140a, and the second P-type junction isolation region 140b is connected to the first P-type junction isolation region 140a. The first P-type junction isolation region 140a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com