Deep depolarization charging method for lead-acid storage battery

A technology of lead-acid battery and charging method, which is applied in the direction of secondary battery charging/discharging, battery circuit device, secondary battery repair/maintenance, etc., can solve problems such as not being accepted by the market, reduce formation time and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

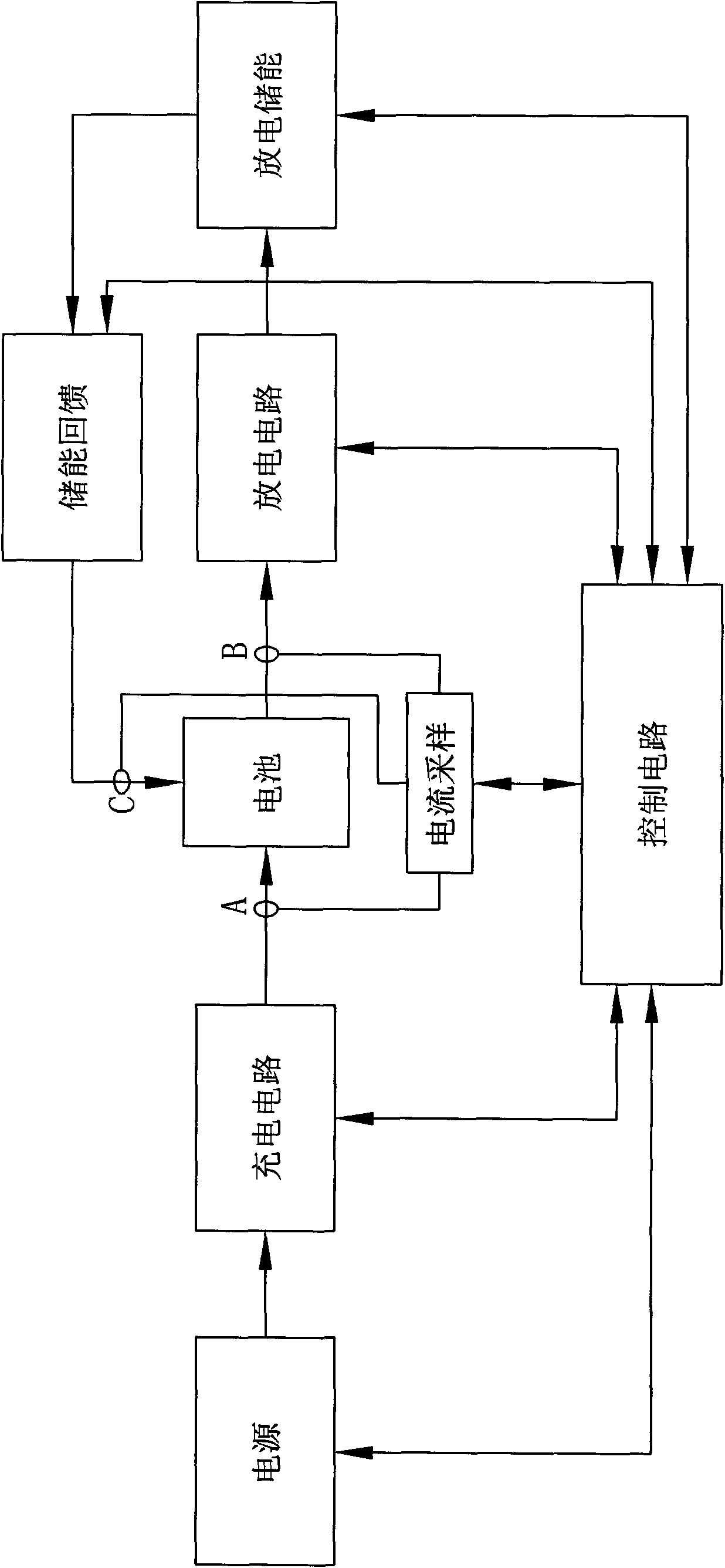

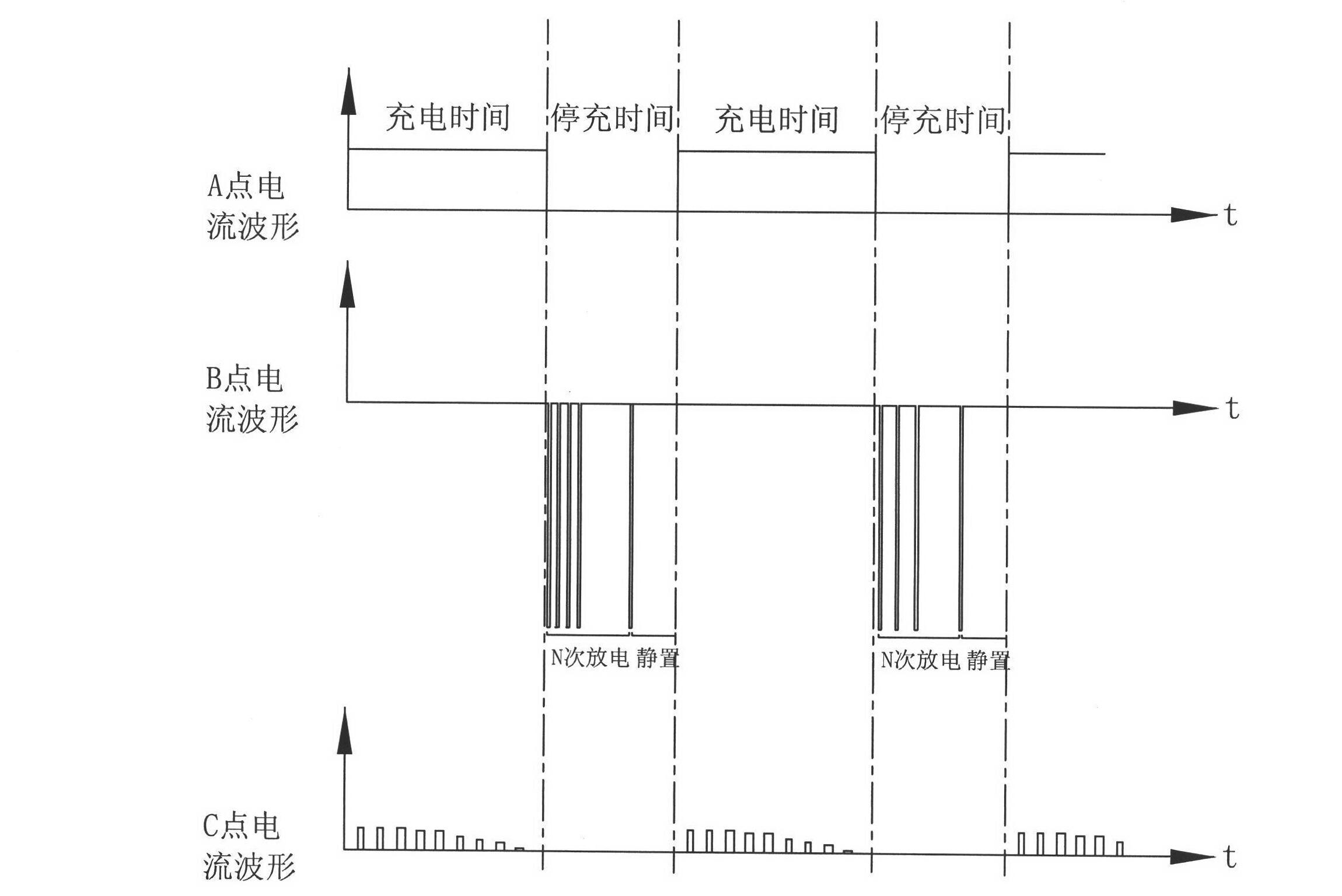

[0026] see figure 2 and image 3 , For the 60V, 22AH battery fast charging circuit, each charging cycle is composed of a charging time Tc and a stop charging time Ts. During the charging time, the charging current Ic is 1.0-1.5C, and the charging current is about 30A. The charging time can be selected from 4 seconds to 30 seconds depending on the conditions. In this example, 10 seconds is selected. The charging stop time is 2 seconds, during which there are a series of discharge pulses and resting time after discharge. The discharge is stored in a capacitor (energy storage capacitor), and the energy on the capacitor is recharged to the battery again during the next charging time. In this example, the discharge pulse width is 0.8ms, the pulse interval is 6ms, and the resting time is 250ms. Therefore, a maximum of 255 discharge pulses are allowed within the charging stop time. 60 minutes to fill 60% of the capacity.

no. 2 example

[0028] see Figure 4 , the energy storage capacitor in the first embodiment is replaced by a resistor, and at the same time, the energy storage feedback unit is canceled, so that the discharge current is consumed by heat generated by the resistor. This is much simpler to control.

no. 3 example

[0030] see Figure 5 and Figure 6 , The practical example of multiplexing circuits sharing one charger, (replaced by 2 circuits in this example) the two circuits are charged and discharged in turn, and the discharged energy storage is fully charged back to the battery. Practice has proved that this is a major innovation in the storage battery industry, and it is of great significance in terms of energy saving and environmental protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com