Horizontal well sewage treatment plant and method thereof

A sewage treatment device and horizontal well technology, which is applied in the field of air flotation separation process and its equipment, and sewage aeration process, can solve the problems of inability to achieve the effect, achieve the effect of increasing the transfer rate, increasing the solubility, and using cleverly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

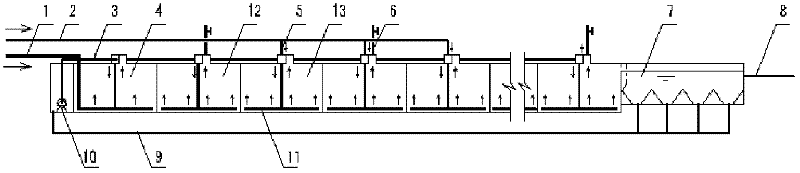

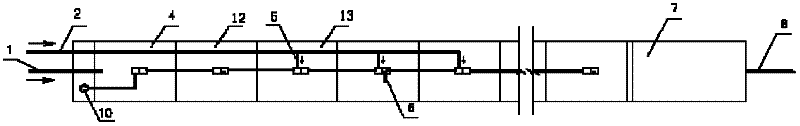

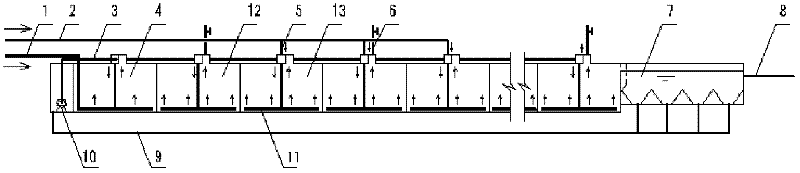

[0034] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

[0035] as attached figure 1 , 2 As shown, the device of the present invention includes compressed air main pipe, branch pipe, external sewage pipeline, diffusion pipe, sewage pipeline, exhaust pipeline, sludge pump, sedimentation tank, return sludge pipeline, mixed liquid pipeline, horizontal well, and is characterized in that The sewage treatment plant is composed of anaerobic zone, anoxic zone, aerobic zone, sedimentation tank and reflux device in sequence from left to right:

[0036] A. Anaerobic zone: It consists of several horizontal wells arranged in sequence. The horizontal wells are covered with inlets and outlets. The external sewage pipeline leads to the first horizontal well in the anaerobic zone. The mixed liquid pipeline flows from The inlet of the leftmost horizontal well is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com