Low temperature decolouring method and device for plant oil

A vegetable oil and decolorization technology, which is applied in the field of vegetable oil refining, can solve the problems of reducing oil quality and oil viscosity, and achieve the effects of reducing energy consumption, reducing losses, and avoiding the generation of catalytic oxidation and decomposition products of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

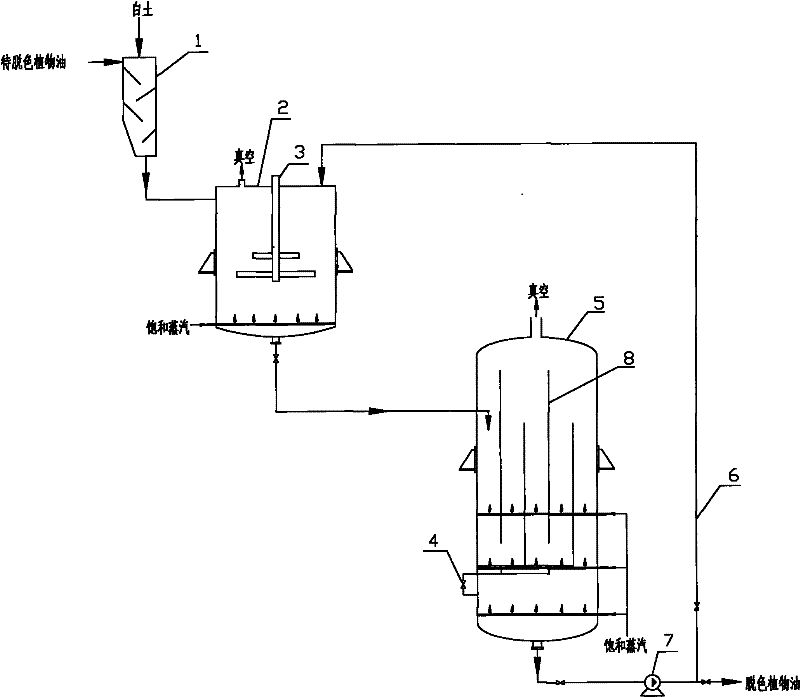

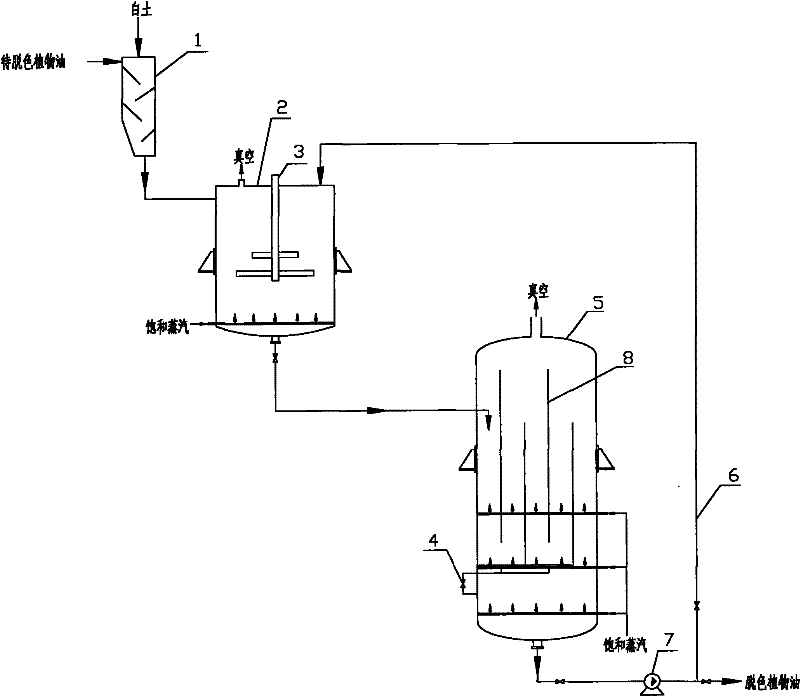

Image

Examples

Embodiment 1

[0020] Soybean neutralized oil first enters the filter equipped with waste decolorizing agent to remove part of phosphorus, soap and pigment, then enters the mixer, and adds 0.5% decolorizing clay to mix with the oil weight, so as to prevent the decolorizing clay from entering the pre-decolorizer in lumps, causing White clay is wasted; then enter the pre-decolorizer, at 85°C, under the action of mechanical stirring and steam stirring of the pre-decolorizer, vegetable oil and bleaching clay are fully mixed and contacted, pre-decolorized for 10 minutes, and part of the pigment in the oil is removed; complete pre-decolorization After decolorization, the decolorized oil enters the decolorizer through the liquid level difference to complete further decolorization. In the decolorizer, the decolorized oil passes through the overflow, and decolorizes in the channels between the baffles in turn, and the decolorization time is guaranteed to be 15 minutes. There is saturated steam in the...

Embodiment 2

[0023] The super degummed soybean oil first enters the filter equipped with waste decolorizer to remove part of the phosphorus and pigment, then enters the mixer, and adds 0.7% decolorized clay for oil mixing to prevent the decolorized clay from entering the pre-decolorizer in lumps, resulting in waste of clay Then enter the pre-decolorizer, at 80°C, under the mechanical stirring and steam stirring of the pre-decolorizer, the vegetable oil and the bleaching clay are fully mixed and contacted, and the pre-decolorization is 7min, and part of the pigment in the oil is removed; after the pre-decolorization is completed , the decolorized oil enters the decolorizer through the liquid level difference to complete further decolorization. In the decolorizer, the decolorized oil passes through the overflow, and decolorizes in the channels between the baffles in turn, and the decolorization time is guaranteed to be 20 minutes. There is saturated steam in the decolorization chamber, and t...

Embodiment 3

[0026] The rapeseed neutralized oil first enters the filter equipped with waste decolorizer to remove part of the phosphorus and soap, then enters the mixer, and adds 0.8% decolorized clay to the oil to mix, so as to prevent the decolorized clay from entering the pre-decolorizer in lumps, resulting in bleaching clay Waste; then enter the pre-decolorizer, at 95°C, under the mechanical agitation and steam agitation of the pre-decolorizer, the vegetable oil and the decolorization clay are fully mixed and contacted, and the pre-decolorization is 10min, and part of the pigment in the oil is removed; the pre-decolorization is completed Finally, the decolorized oil enters the decolorizer through the liquid level difference to complete further decolorization. In the decolorizer, the decolorized oil passes through the overflow, and decolorizes in the channels between the baffles in turn, and the decolorization time is guaranteed to be 15 minutes. There is saturated steam in the decolor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com