Annular wind power permanent magnetic direct-driven generator

A technology of permanent magnet direct drive and generator, which is applied in the direction of wind power engine, wind power motor combination, wind power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

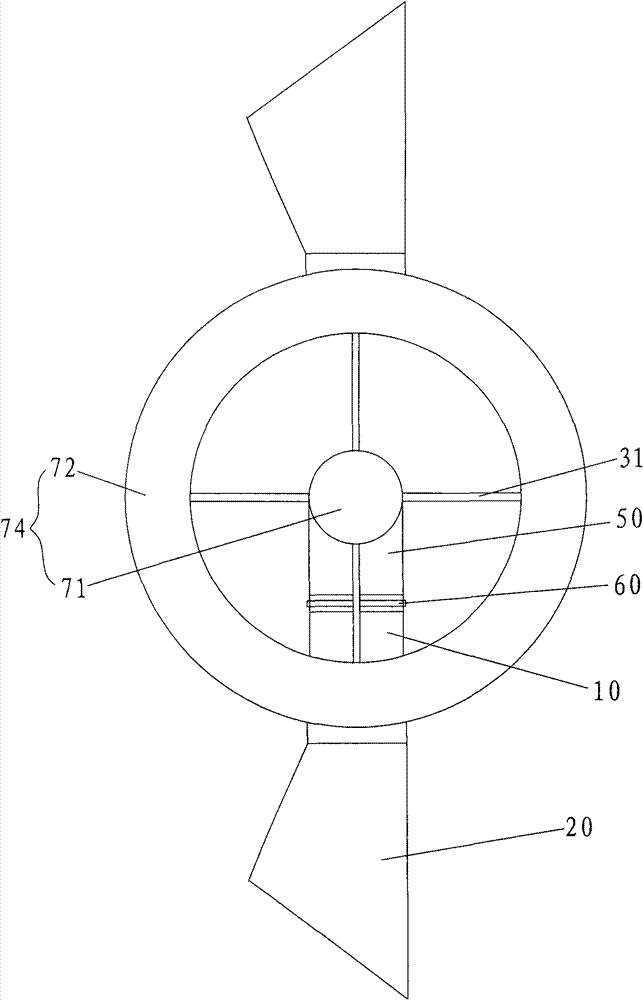

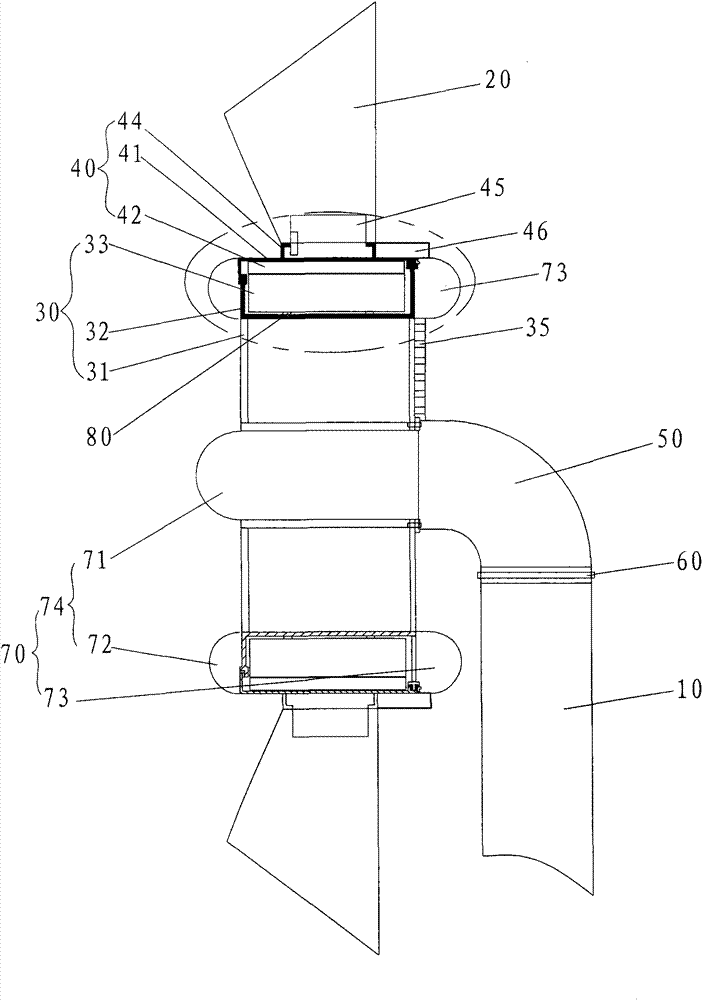

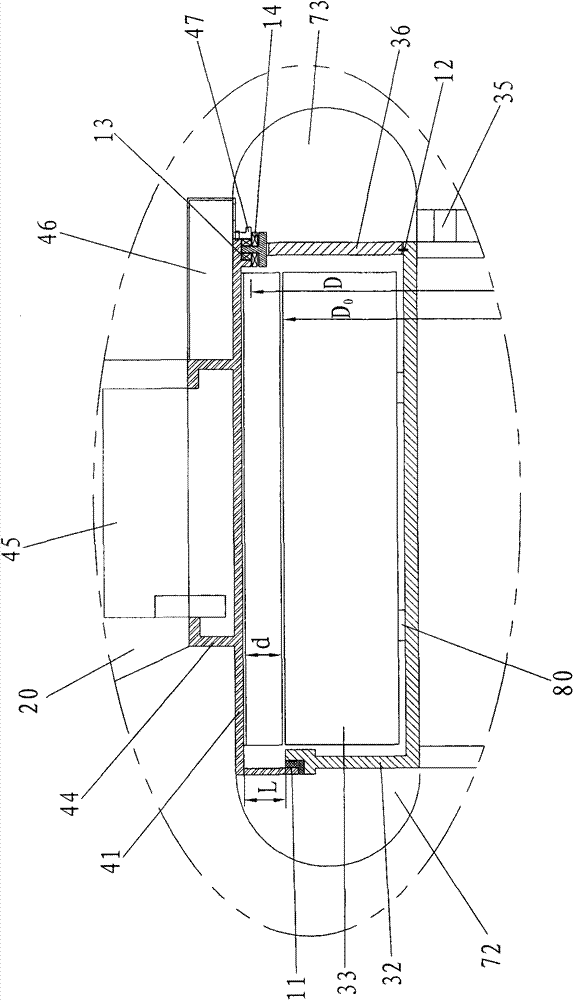

[0035] Such as Figure 1 to Figure 3 As shown, the present invention discloses an annular wind-driven permanent magnet direct-drive generator, including a tower 10 , a base, blades 20 , a stator 30 , a rotor 40 , an elbow 50 , a yaw bearing 60 and a fairing 70 .

[0036] The tower 10 is installed on a foundation (not shown in the figure).

[0037] The blades 20 are directly installed on the rotor 40, eliminating the need for a wind wheel link.

[0038] There are many specific structures of the rotor 40 . The rotor 40 of this embodiment is composed of a rotor drum 41 and a permanent magnet 42 . The rotor drum 41 is cast and processed by nodular cast iron, the rotor drum 41 is cylindrical, and the permanent magnet 42 is installed inside the rotor drum 41 . In order to facilitate the assembly of the blades 20, in this embodiment, two to three hollow seats 44 are directly formed by casting on the outside of the rotor drum 41 for installing the blades 20, and the roots of the bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com