Water-testing seal plug and water testing method thereof

A technology for sealing plugs and testing water, which is applied in the sealing of engines, the use of liquid/vacuum for liquid tightness measurement, and the detection of fluid appearance at leak points, etc. It can solve problems that affect production efficiency and are not suitable for assembly line operations. , to achieve the effects of simple structure, easy operation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

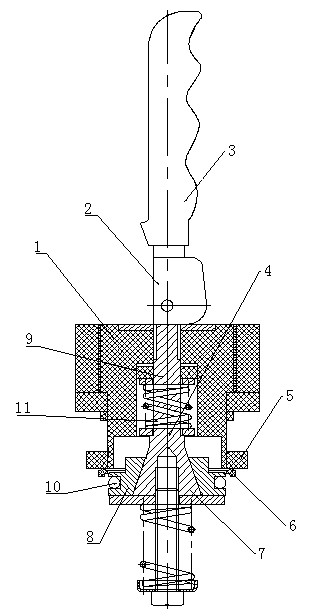

[0014] figure 1 Shown is a schematic cross-sectional structure of the present invention.

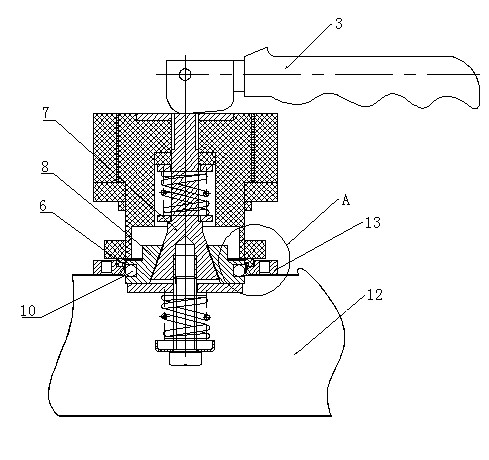

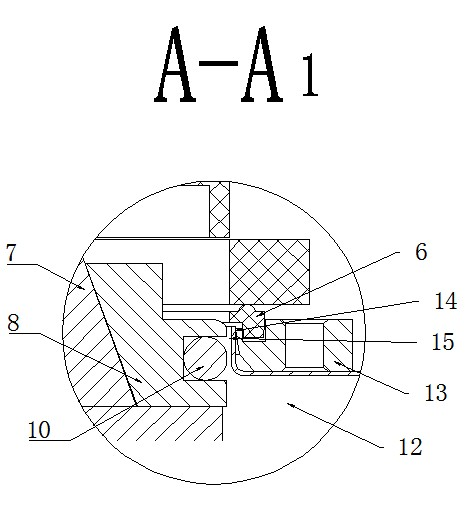

[0015] figure 2 Shown is a partial enlarged cross-sectional structure diagram of the present invention.

[0016] The invention includes a housing 1, a cam 2, a handle 3, an expansion mechanism 4, a front retaining ring 5 and a sealing ring 6.

[0017] The housing 1 is a cylinder with a stepped hole in the middle, and a pit is provided on the upper part. The pit is inlaid with a wear-resistant working surface. The inner stepped hole is the working area of the expansion mechanism 4. The outer front end of the housing 1 is equipped with a front The retaining ring 5 and the sealing ring 6 are located outside the front retaining ring 5.

[0018] The cam 2 has two cam contact surfaces connected by arcs. The distances between the two cam contact surfaces and the axis of rotation are not equal. The cam 2 is located above the outside of the housing 1, and its cam contact surface is connected to the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com