Purification system and method for high-dust concentration supersaturated peculiar smell gas

A purification system and gas technology, which is applied in the field of purification system of high dust content and supersaturated odor gas, can solve the problems of high temperature resistance of plastic burning plate, high investment of circulating water system, large area occupation, etc., and achieve good purification effect and clean air. Efficient and adaptable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

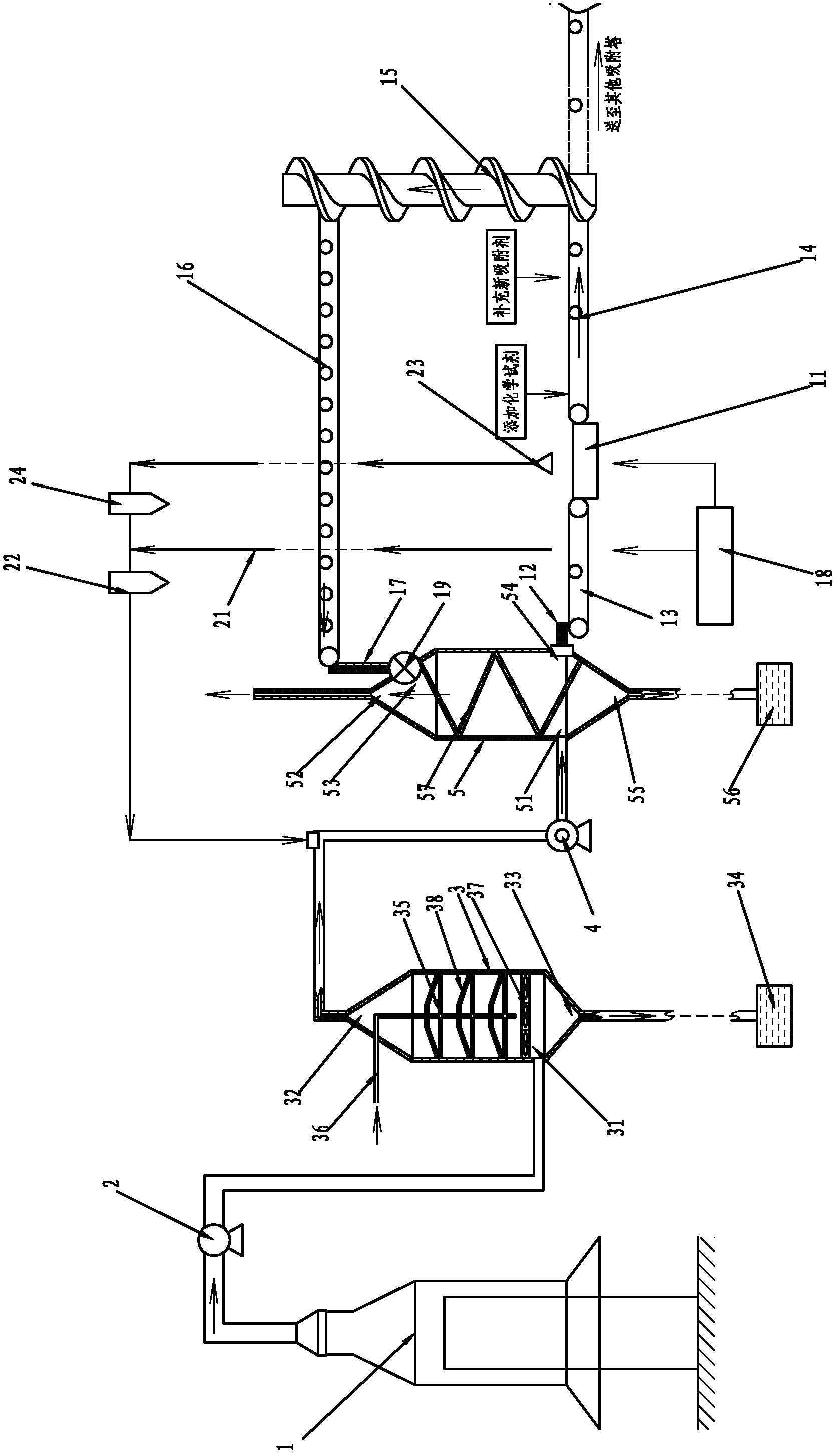

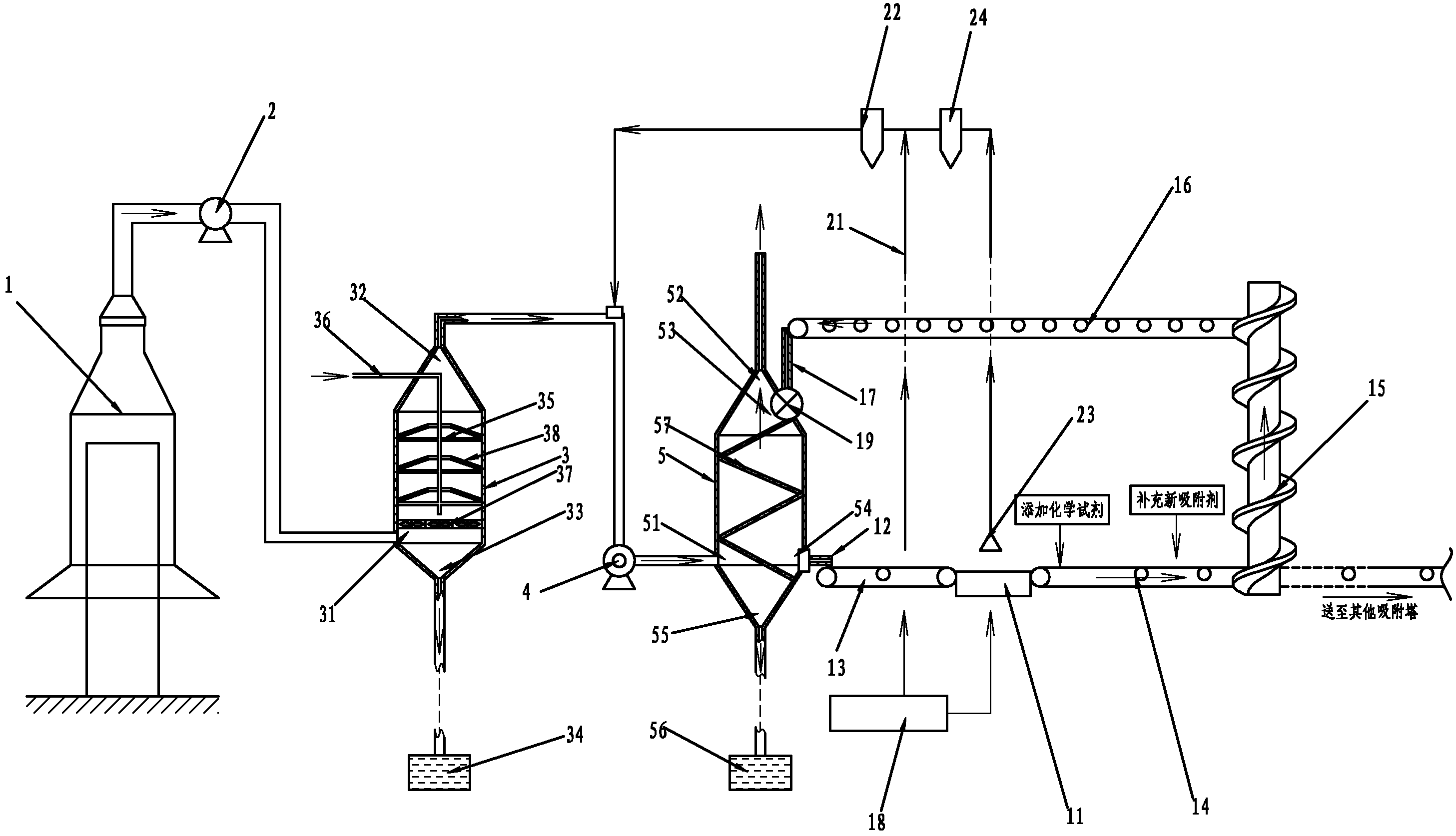

[0017] Such as figure 1 As shown, the purification system for highly dusty and supersaturated odorous gas of the present invention includes a gas collection cover 1, a first induced draft fan 2, a demist and dust removal tower 3, a second induced draft fan 4, and an adsorption purification tower 5.

[0018] A flue gas inlet 31 is arranged at the bottom of the mist and dust removal tower 3 , a gas outlet 32 is arranged at the top, a sewage outlet 33 is arranged at the bottom, and a sewage pool 34 is arranged below the sewage outlet 33 . Several layers of mist eliminators 38 are arranged above the flue gas inlet 31 inside the mist removal and dust removal tower 3, figure 1 Shown in three layers, demister 38 optional figure 1 As shown in the ridge type or plate type, the spray main pipe 36 passes through the mist eliminator 38, and the spray main pipe 36 communicates with each spray branch pipe 35, and the inlet end of the spray main pipe 36 is connected to the spray liquid st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com