Single-servo power tool rest

A technology of power tool rest and power switching, which is used in metal processing equipment and other directions to achieve the effects of increasing reliability, reducing costs and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

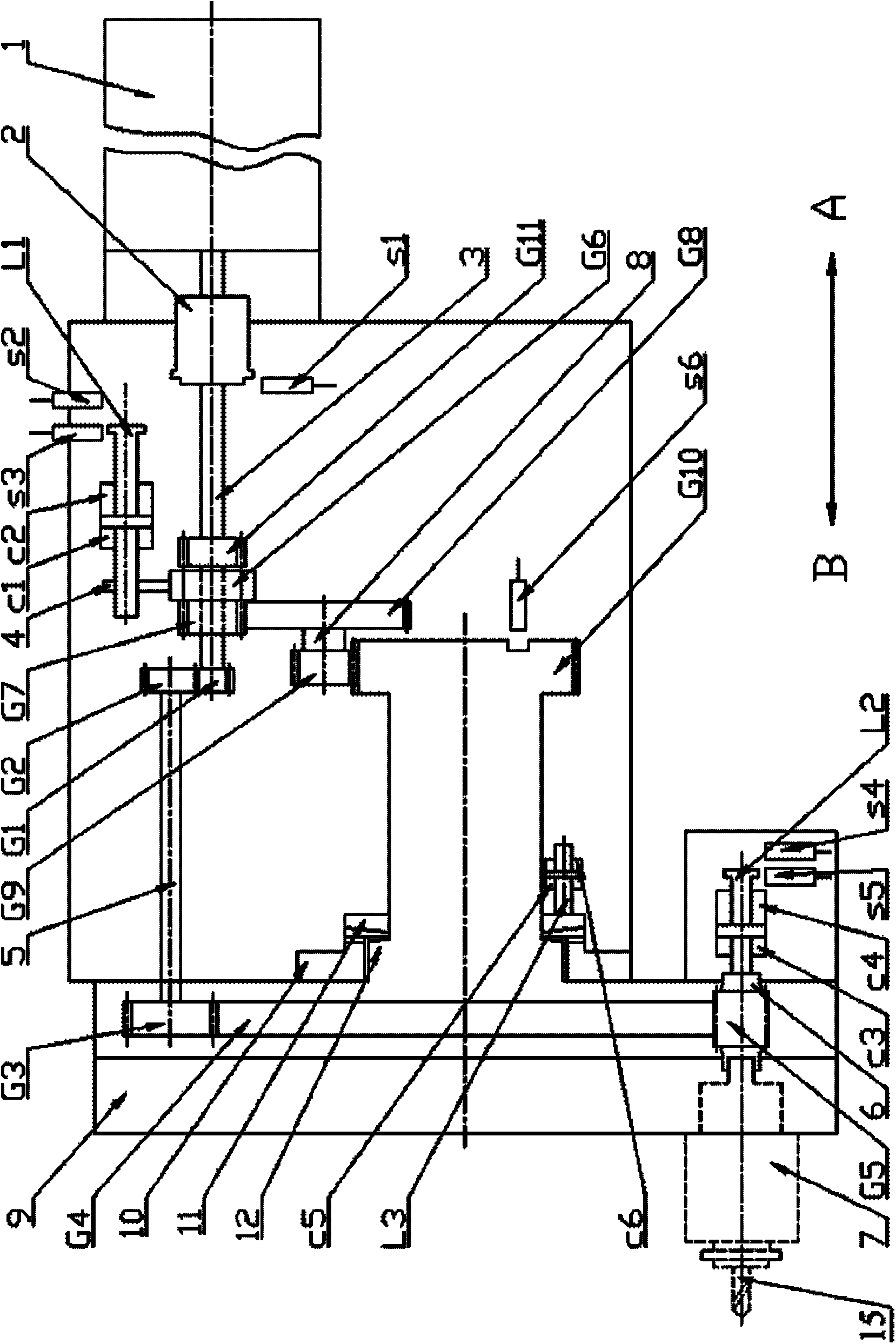

[0019] like figure 1 As shown, for a single servo power tool post, the servo motor 1 is connected to the power input shaft 3 of the tool post body through the torque limiter 2, and the transmission torque on the torque limiter 2 is measured through the proximity switch Is1 to see if it is overloaded; When the torque is less than the preset value, the torque limiter 2 rotates normally, and the proximity switch Is1 has no induction signal; when the torque is overloaded, that is, the torque is greater than the preset value, the internal structure of the torque limiter 2 slips, and the proximity switch Is1 generates an induction signal.

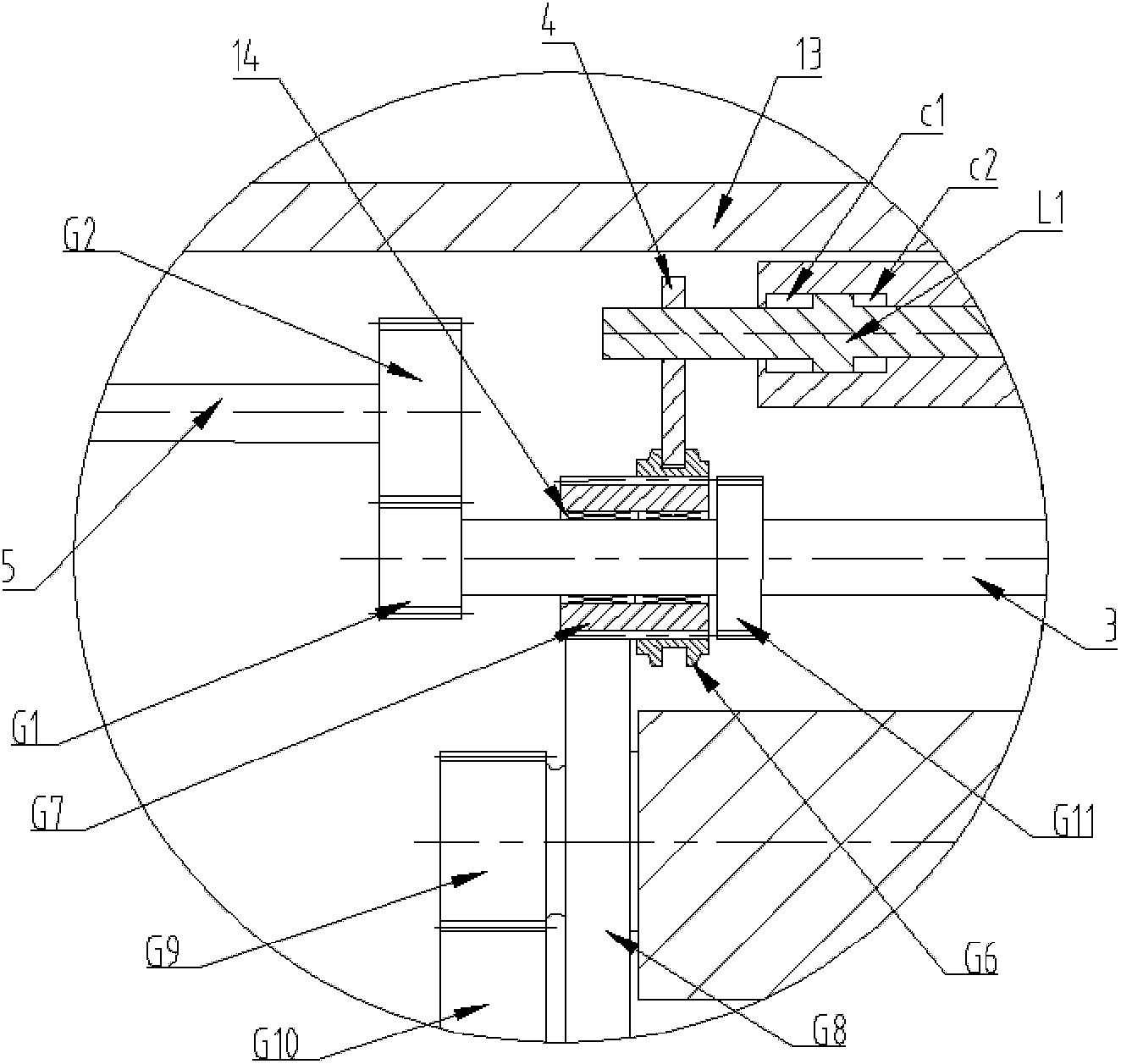

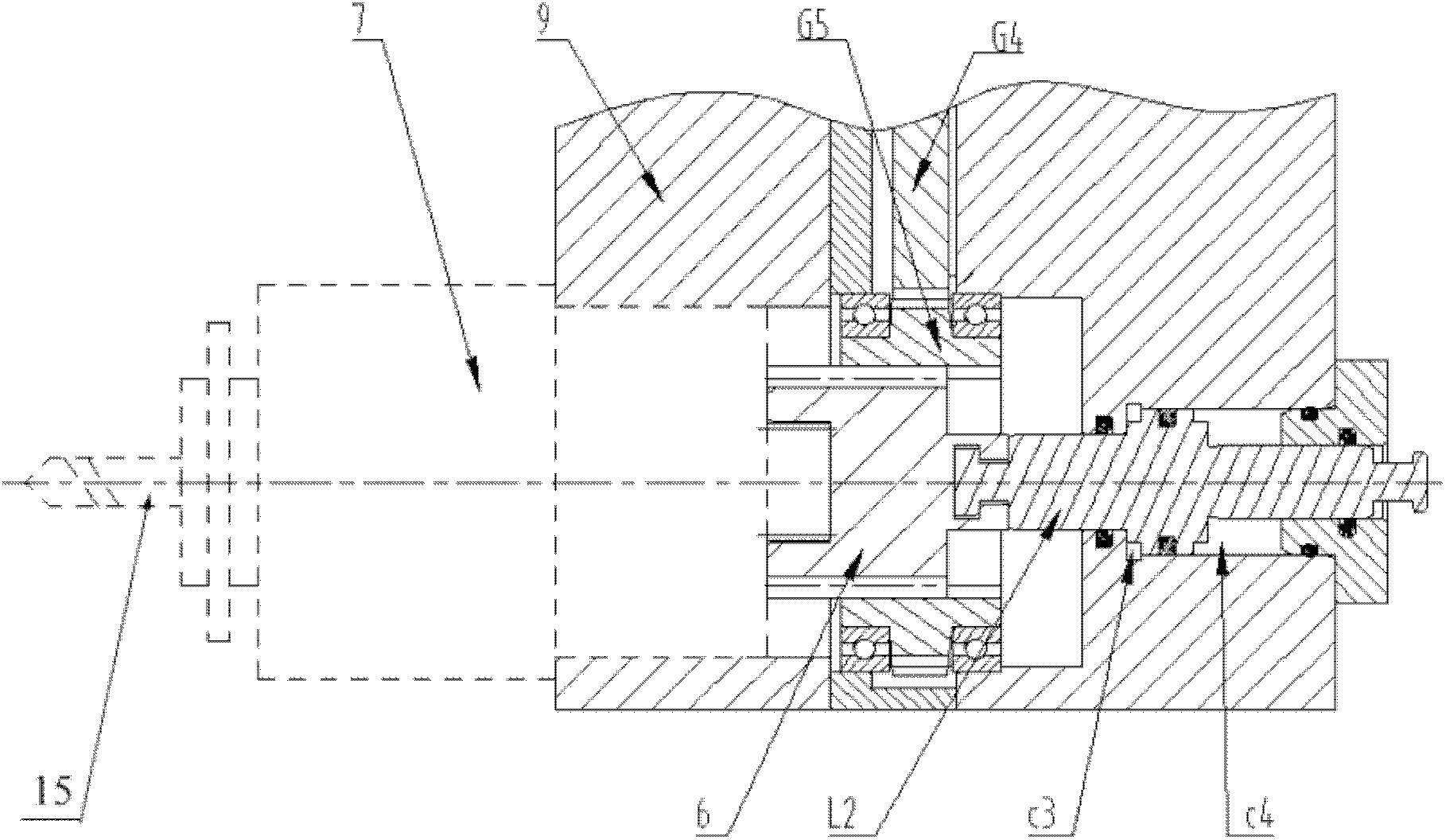

[0020] like figure 2 As shown, the slip gear clutch device includes power input shaft 3, input shaft cutterhead side gear G11, slip gear G6, power switching gear IG7, power switching gear IIG1, shift fork 4 and piston IL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com