Work-piece locating and bonding device

A technology for bonding devices and workpieces, applied in work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of inconsistent thickness uniformity of the adhesive layer, insufficient operation convenience, inconsistent thickness uniformity, etc., and achieve the thickness of the adhesive layer. Controllable, consistent adhesive layer thickness, consistent thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

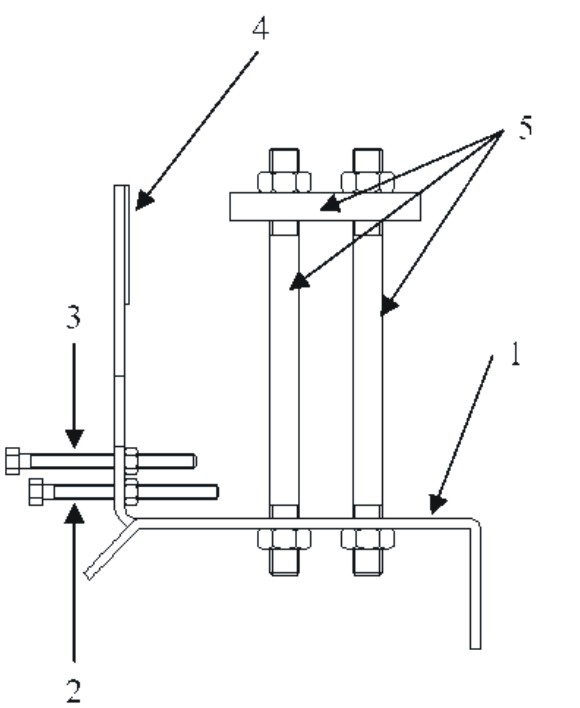

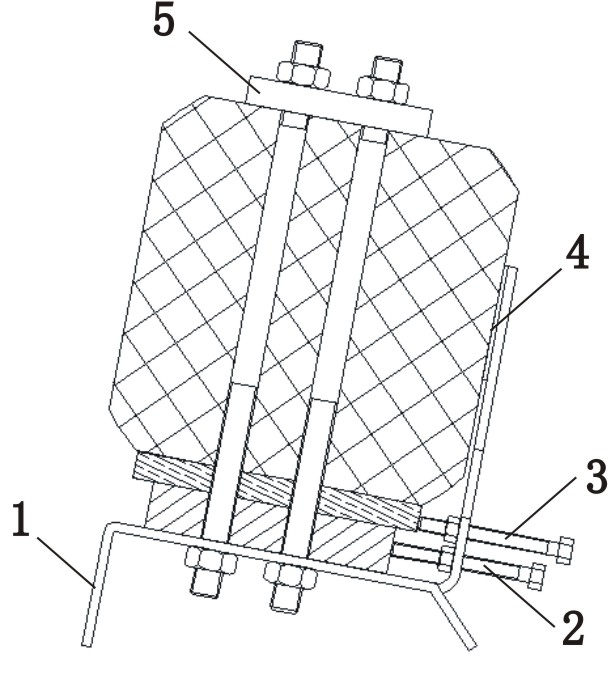

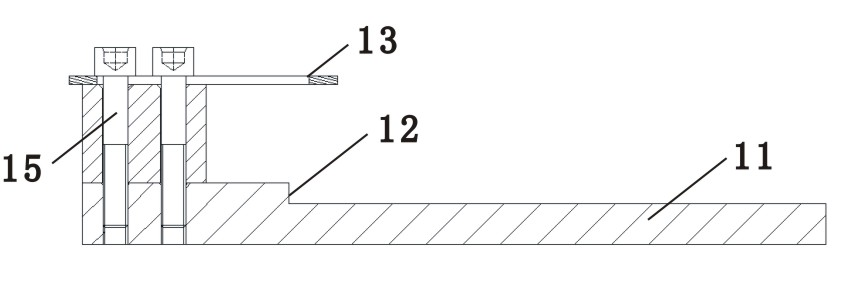

[0043]The workpiece positioning bonding device of the present invention includes a workpiece connecting piece and a cutting pad bonding device and a workpiece pad and a workpiece bonding device, wherein: the workpiece connecting piece and cutting pad bonding device includes a first placement base 11, a second A positioning ladder 12, a cutting pad positioning piece 13, a first fixed weight pressing block 14 and a vertical screw 15, the first positioning ladder 12 intersects vertically with the plane where the first placement base 11 is located, and the cutting The plane where the pad positioning piece 13 is located is parallel to the first placement base 11 , and the cutting pad positioning piece 13 , the first positioning ladder 12 and the first placement base 11 are fixedly connected by a screw rod 15 . The workpiece pad and the workpiece bonding device include a second placement base 21, a second positioning ladder 22, a reversible workpiece fixing fence 23, a tension rod 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com