Modularized combined type all-electric rubber injection machine

A combined and modular technology, applied in the field of rubber injection machines, can solve problems such as low production efficiency, low production efficiency, product cracking, etc., and achieve the effect of reducing product production costs, equipment investment costs, and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

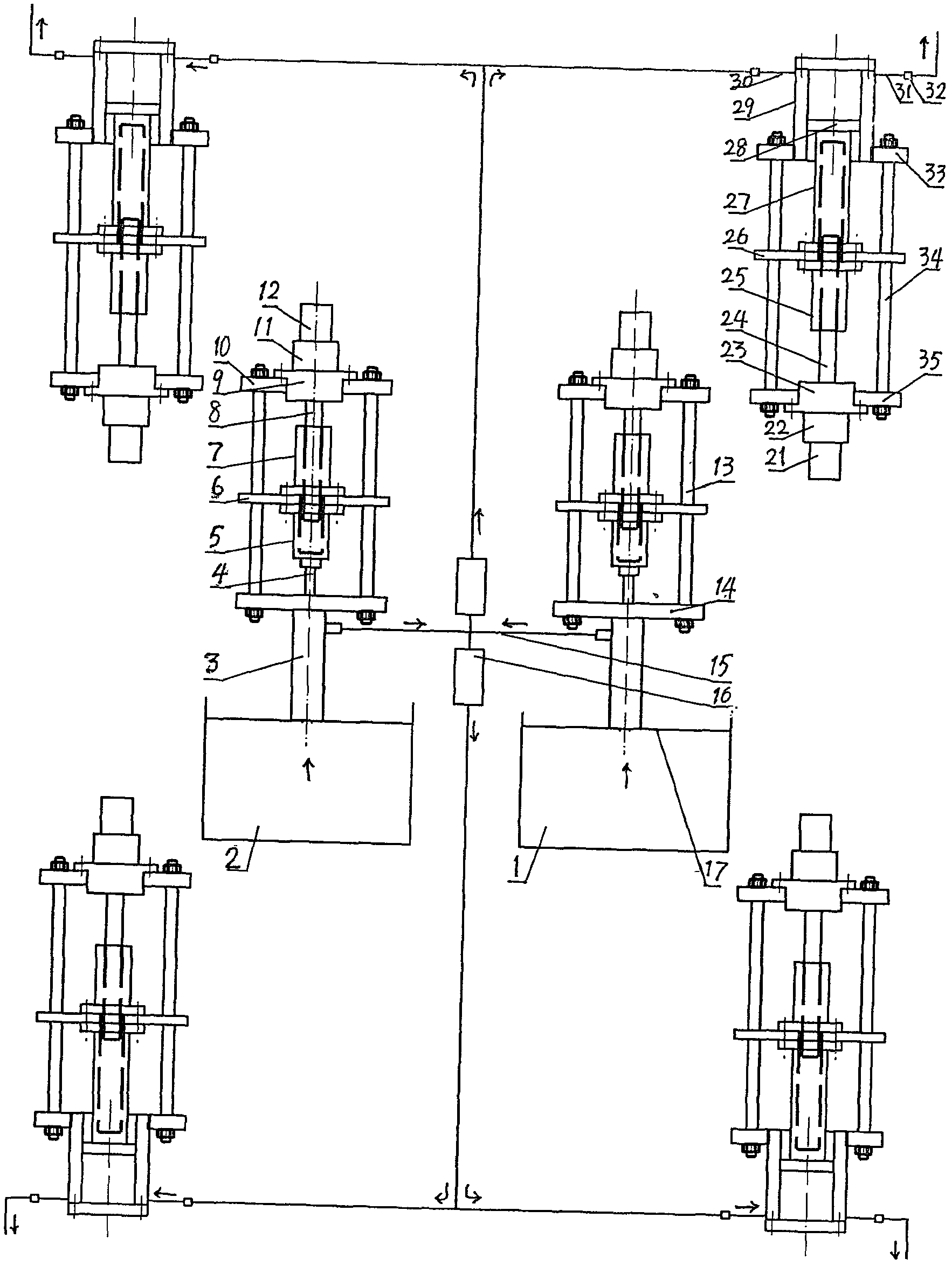

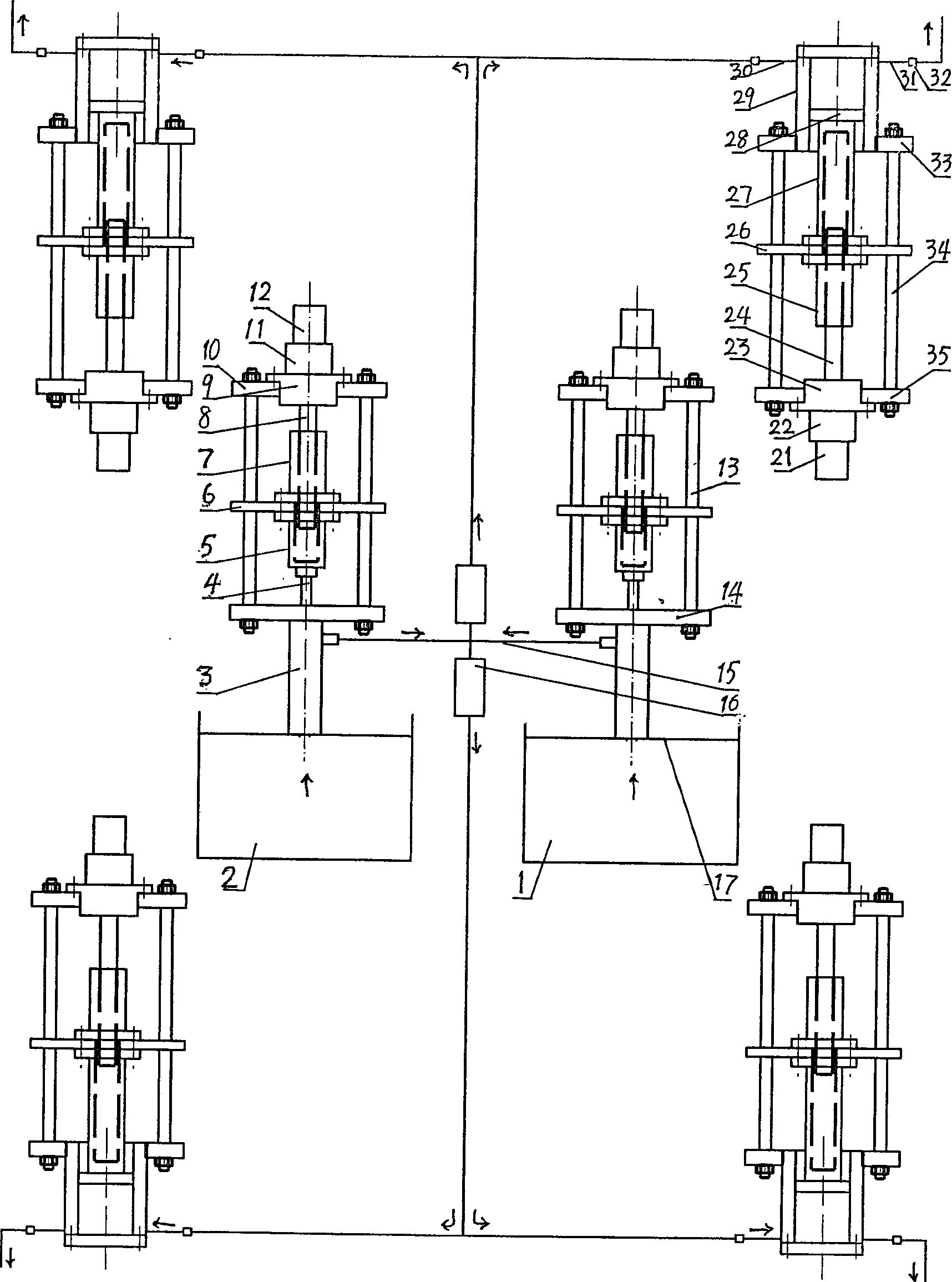

[0009] The following structural embodiments of the present invention will be described in detail with reference to the accompanying drawings: Now take the all-electric rubber injection machine combined with two metering pump units and four injection units as an example, see the accompanying drawings, this modular combined all-electric rubber injection machine , including a metering pump unit and an injection unit. There are material pipes 15, 30, and 31 connected in series between them. There is a stop valve 32 on the material pipe. The metering pump unit is an all-electric metering pump unit. The lower end of the pump body 3 The feed inlet of the pump is in contact with the A component 1 or B component 2 in the barrel through the pressure plate 17, the pump body shaft 4 is connected with the ball screw nut 7 through the connecting sleeve 5, the upper part of the ball screw shaft 8 is connected with the bearing seat 9 The precision planetary gear box 11 is connected, the servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com