Method for separating carbon nanotubes with different conductive performances

A technology of carbon nanotubes and electrical conductivity, which is applied in the field of separating carbon nanotube materials with different electrical conductivity, can solve the problems of high price and difficult mass production, and achieve the effect of high selectivity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

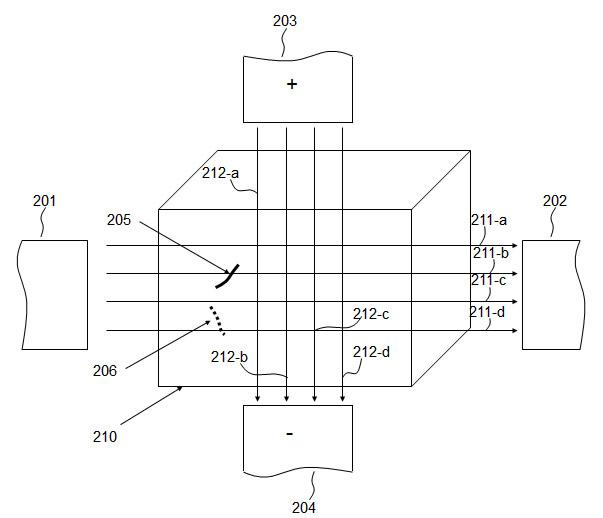

[0021] figure 2 It is a schematic diagram of the carbon nanotube separation method of the present invention, that is, a schematic diagram of a method for separating metallic carbon nanotubes and semiconducting carbon nanotubes, wherein the carbon nanotube 205 is one of a plurality of metallic carbon nanotubes, The carbon nanotube 206 is one of a plurality of semiconducting carbon nanotubes. These carbon nanotubes are soaked in the liquid in the container 210 . The magnetic pole 201 is an N pole or an S pole, and the magnetic pole 202 is an S pole or an N pole. In this way, the two opposite magnetic poles of the magnetic pole 201 and the magnetic pole 202 constitute a magnetic field. The magnetic force lines 211 - a , 211 - b , 211 - c , 211 - d represent the magnetic force lines between the magnetic pole 201 and the magnetic pole 202 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com