Flame-retardant adhesive additive, and flame-retardant adhesive and application method thereof

A flame-retardant adhesive and additive technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of smoldering when thrown in quilts, wood shavings, wood chips or grass Tens of minutes, high risk, etc., to achieve the effects of fire reduction, fire prevention, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Flame retardant additives and preparation of new flame retardant joint glue:

[0023] Add 2 grams of hydroxypropyl methylcellulose into 118 grams of water, stir and dissolve until a clear and transparent solution, then add 30 grams of ammonium dihydrogen phosphate, and stir until completely dissolved. Then weigh 850 grams of ordinary high-speed cigarette mouthpiece glue in a blender, slowly add the flame retardant glue additive while stirring until completely mixed evenly.

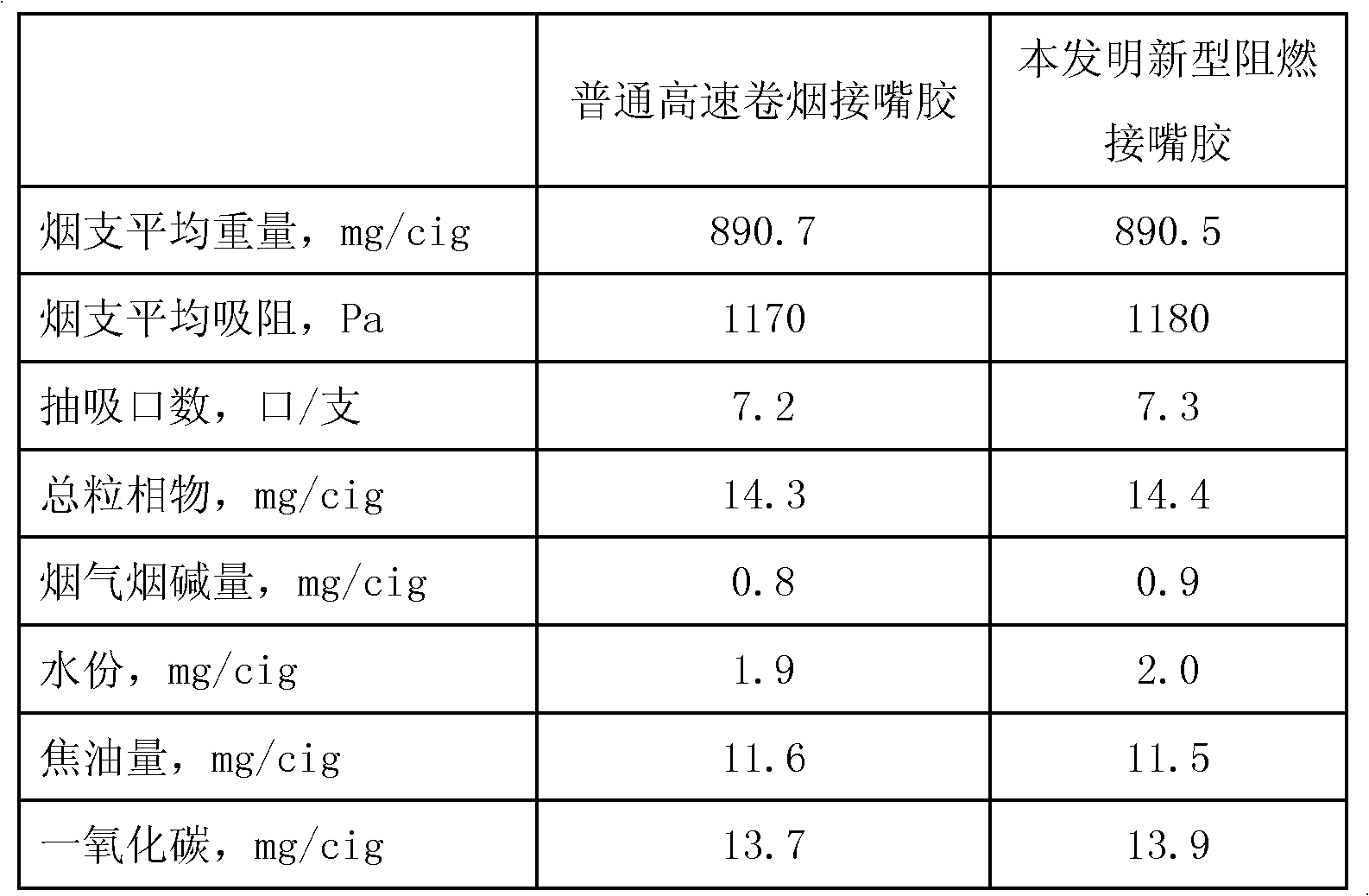

[0024] The above-mentioned new type of flame-retardant mouthpiece glue and common high-speed cigarette mouthpiece glue, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to the conventional production method. The quality of the two cigarette samples (aroma, harmony, odor, irritation, aftertaste, etc.) was evaluated by professional smokers. At the same time, the routine chemical indicators of the mainst...

Embodiment 2

[0035] Flame retardant additives and preparation of new flame retardant joint glue:

[0036] Add 2 grams of hydroxypropyl methylcellulose into 118 grams of water, stir and dissolve until a clear and transparent solution, then add 20 grams of ammonium dihydrogen phosphate and 20 grams of diammonium hydrogen phosphate, and stir until completely dissolved. Then weigh 850 grams of ordinary high-speed cigarette mouthpiece glue in a blender, slowly add the flame retardant glue additive while stirring until completely mixed evenly.

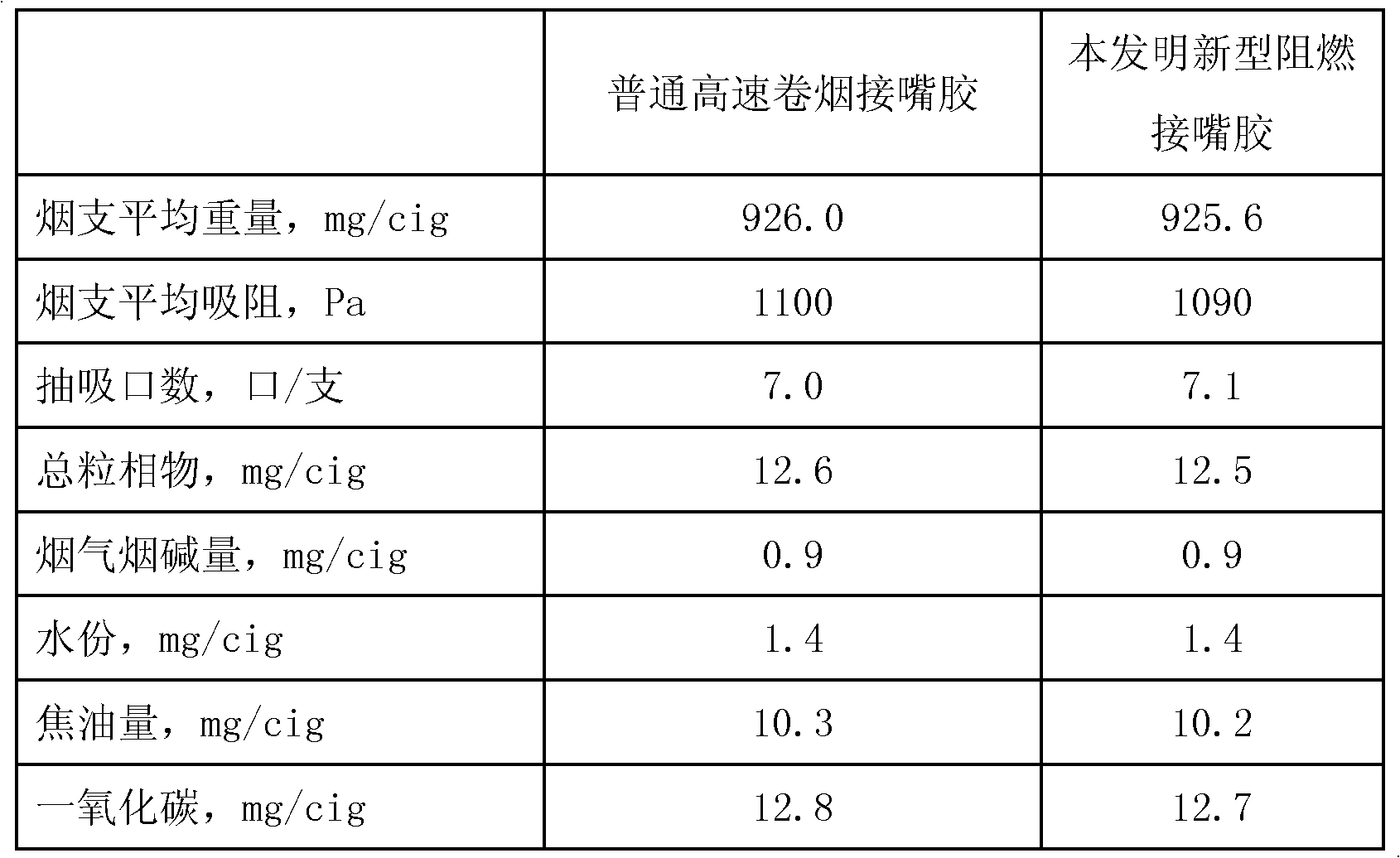

[0037] The above-mentioned new type of flame-retardant mouthpiece glue and common high-speed cigarette mouthpiece glue, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to the conventional production method. The quality of the two cigarette samples (aroma, harmony, odor, irritation, aftertaste, etc.) was evaluated by professional smokers. At the same time,...

Embodiment 3

[0048] Flame retardant additives and preparation of new flame retardant joint glue:

[0049] Add 5 grams of xanthan gum to 118 grams of water, stir and dissolve to a clear and transparent solution; then add 40 grams of ammonium dihydrogen phosphate, and stir until completely dissolved; finally add 3 grams of food-grade titanium dioxide, and stir to a uniform suspension. Then weigh 850 grams of ordinary high-speed cigarette tip glue in a blender, and slowly add the above-mentioned flame retardant glue additive aqueous solution while stirring until completely mixed evenly.

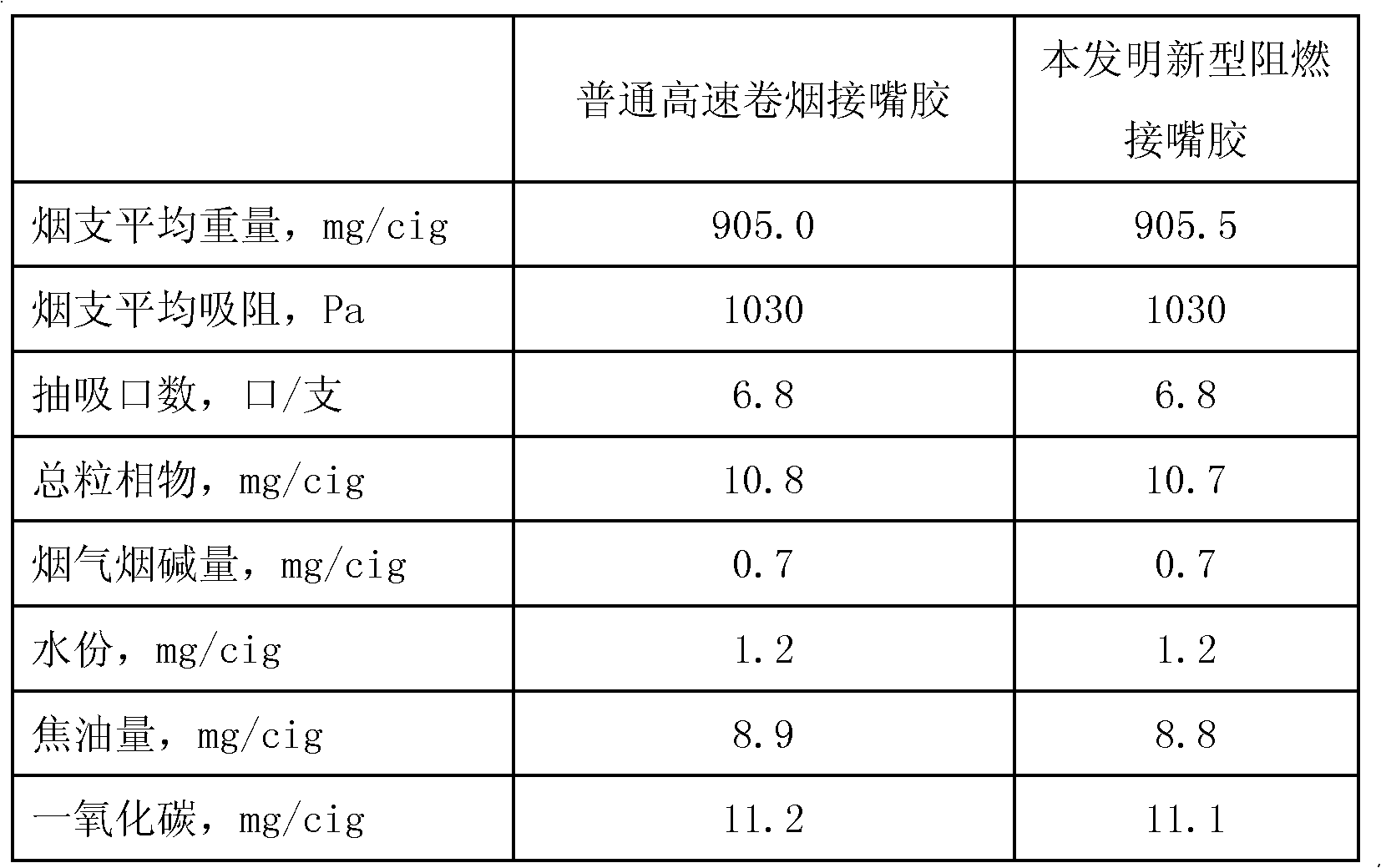

[0050] The above-mentioned new type of flame-retardant mouthpiece glue and common high-speed cigarette mouthpiece glue, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to the conventional production method. The quality of the two cigarette samples (aroma, harmony, odor, irritation, aftertaste, etc.) was evalua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com