Application method of flame retardant paint, as well as flame-retardant cigarette tipping paper and cigarette

A cigarette tipping paper and flame retardant technology, applied in paper coating, papermaking, coating, etc., can solve the problem of throwing in quilts, shavings, wood chips or grass, smoldering for tens of minutes, and great danger, etc. problems, to achieve the effect that the chemical indicators of flue gas basically do not change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of flame retardant coating and new flame retardant cigarette tipping paper:

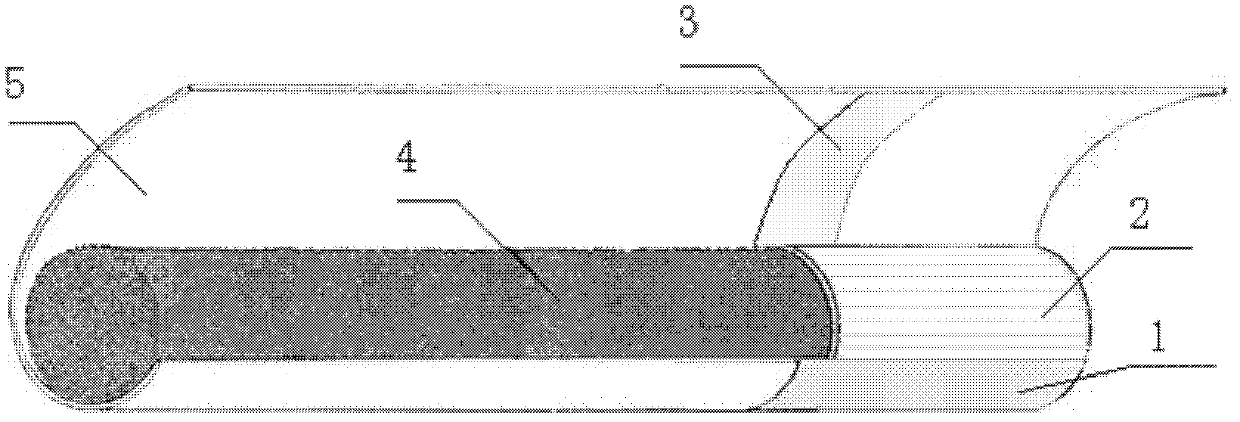

[0031] Slowly add 200 grams of hydroxypropyl methylcellulose to 10 kilograms of water while stirring, dissolve to a clear and transparent solution, then add 2,500 grams of ammonium dihydrogen phosphate, stir until completely dissolved, and then form a flame retardant coating; then inject it In the ink tank of the cigarette tipping paper printing (gravure printing) machine, a layer of flame-retardant tape of a certain width is coated on the back of the ordinary cigarette tipping paper. The cigarettes are rolled into cigarettes on the cigarette rolling machine.

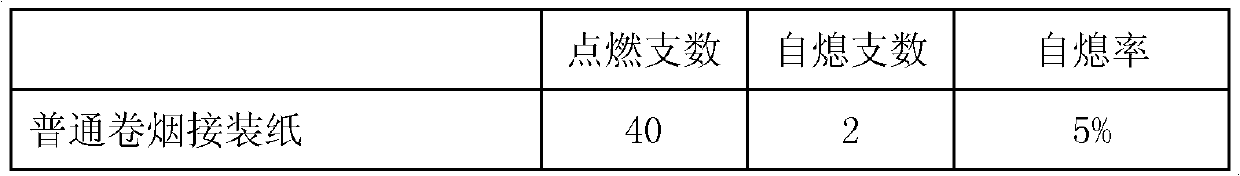

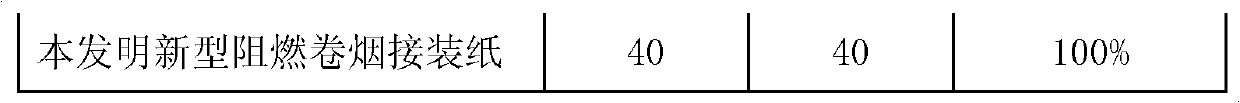

[0032] The above-mentioned new flame-retardant cigarette tipping paper and ordinary tipping paper, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to the conventional production method. The quality of the two cigarette sample...

Embodiment 2

[0041] Preparation of flame retardant coating and new flame retardant cigarette tipping paper:

[0042] Slowly add 200 grams of xanthan gum while stirring in 10 kilograms of water, dissolve to a clear and transparent solution, then add 2000 grams of ammonium dihydrogen phosphate and 1000 grams of diammonium hydrogen phosphate, and stir until completely dissolved to form a flame retardant coating; then Pour it into the ink tank of the cigarette tipping paper printing (gravure printing) machine, and coat a layer of flame-retardant tape with a certain width on the back of the ordinary cigarette tipping paper. After drying, the coated tipping paper is cut into disks , and then rolled into cigarettes on the cigarette rolling machine.

[0043] The above-mentioned new flame-retardant cigarette tipping paper and ordinary tipping paper, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to ...

Embodiment 3

[0053] Preparation of flame retardant coating and new flame retardant cigarette tipping paper:

[0054] Slowly add 150 grams of tamarind polysaccharide gum while stirring in 10 kilograms of water, dissolve to a clear and transparent solution, then add 1000 grams of ammonium dihydrogen phosphate, 1000 grams of diammonium hydrogen phosphate and 1000 grams of ammonium phosphate, and stir until completely dissolved, that is Then inject it into the ink tank of cigarette tipping paper printing (gravure printing) machine, and coat a layer of flame retardant tape with a certain width on the back of ordinary cigarette tipping paper. Dried, cut into discs, and then rolled into cigarettes on a cigarette rolling machine.

[0055] The above-mentioned new flame-retardant cigarette tipping paper and ordinary tipping paper, the same shredded tobacco and other auxiliary materials were used respectively, and two kinds of cigarette samples were rolled and joined according to the conventional pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com