High-viscosity dispersion-resistant grouting material

A grouting material, anti-dispersion technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem that the viscosity of polyurethane slurry cannot be adjusted in a wide range, hinder the diffusion of internal uncured slurry, and cannot be driven Displacement and diffusion boundaries and other problems, to achieve the effect of clear displacement and diffusion interface, good dyeing effect, and strong anti-dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

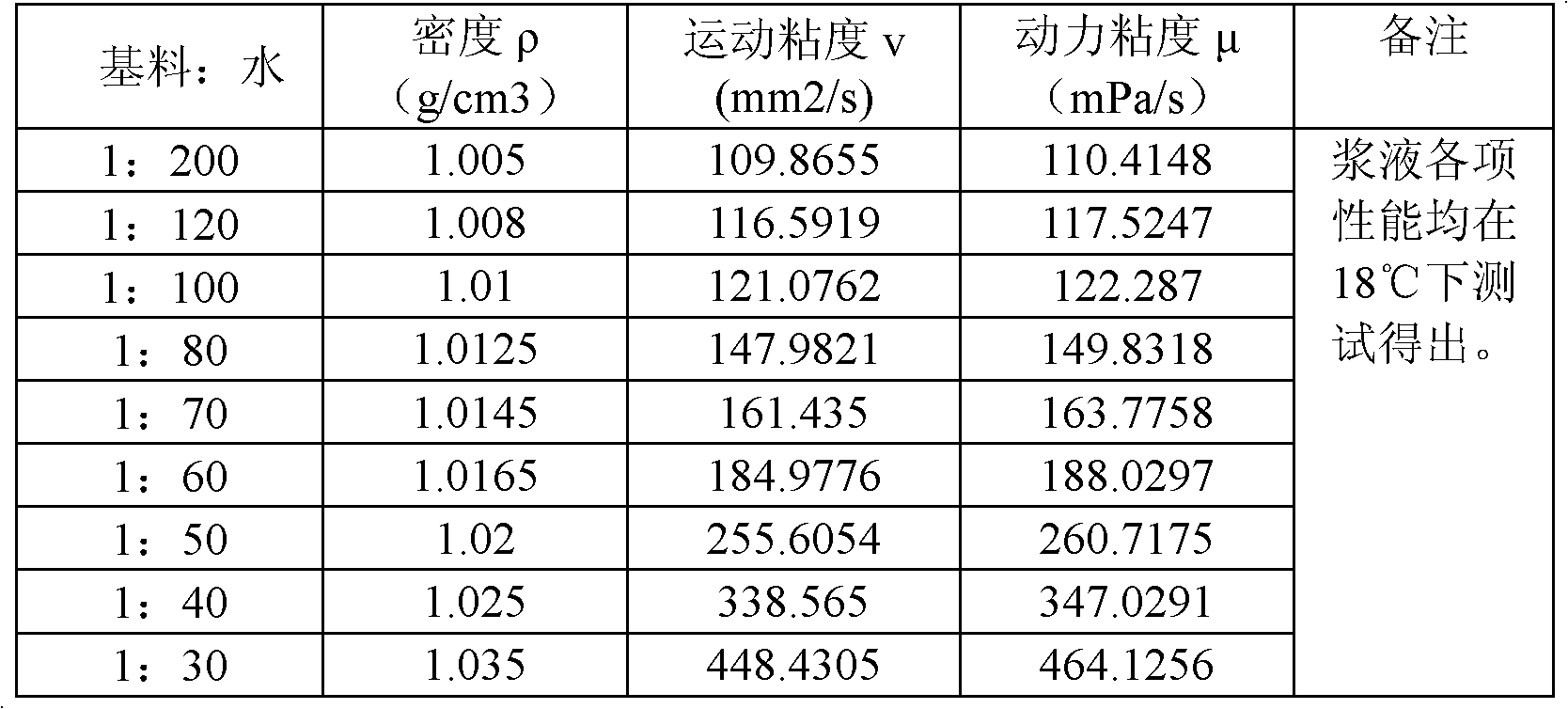

[0022] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:30, and the mass ratio of dyeing agent to water is 1:100. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide and water in the polyacrylamide solution is 1:8; the mass ratio of poinsettia and water in the poinsettia solution is 1:2. (Poinsettia is actually acid fuchsin, molecular weight: 566.48)

[0023] Preparation method: first mix polyacrylamide and dyeing agent evenly, then sprinkle the mixed material into water evenly while stirring, let stand for 5-10 minutes to fully dissolve the base material, and re-stir evenly to complete the preparation of the slurry.

[0024] During the slurry preparation process, the materials must be evenly sprinkled while stirring to avoid the form...

Embodiment 2

[0026] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:100, and the mass ratio of dyeing agent to water is 1:300. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide to water in the polyacrylamide solution is 1:10; the mass ratio of poinsettia to water in the poinsettia solution is 1:4.

[0027] Preparation method: Example 1 at the same time.

Embodiment 3

[0029] The high-viscosity anti-dispersion grouting material is prepared from polyacrylamide base material, water and dyeing agent. The mass ratio range of polyacrylamide base material to water is 1:200, and the mass ratio of dyeing agent to water is 1:200. The dyeing agent is made by mixing polyacrylamide solution and poinsettia solution at a mass ratio of 1:1 and then drying; the mass ratio of polyacrylamide to water in the polyacrylamide solution is 1:10; the mass ratio of poinsettia to water in the poinsettia solution is 1:3.

[0030] Preparation method: Example 1 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com