Control method and control system for energy saving of dust removing fan for mains frequency melting furnace

A technology of dust removal fan and control method, which is applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of prolonging smelting time, waste of electric energy by dust removal fan, waste of power frequency heating power, etc., to shorten the smelting time, The effect of reducing work intensity and ensuring safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

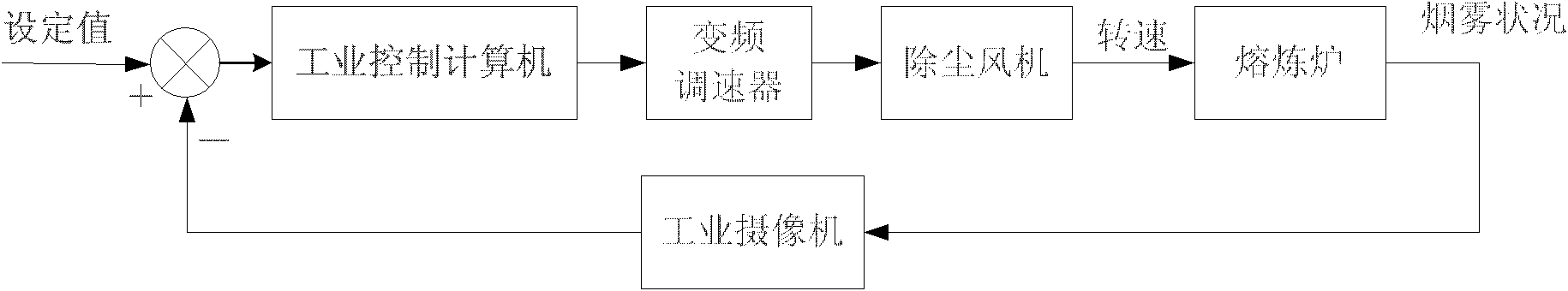

[0045] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

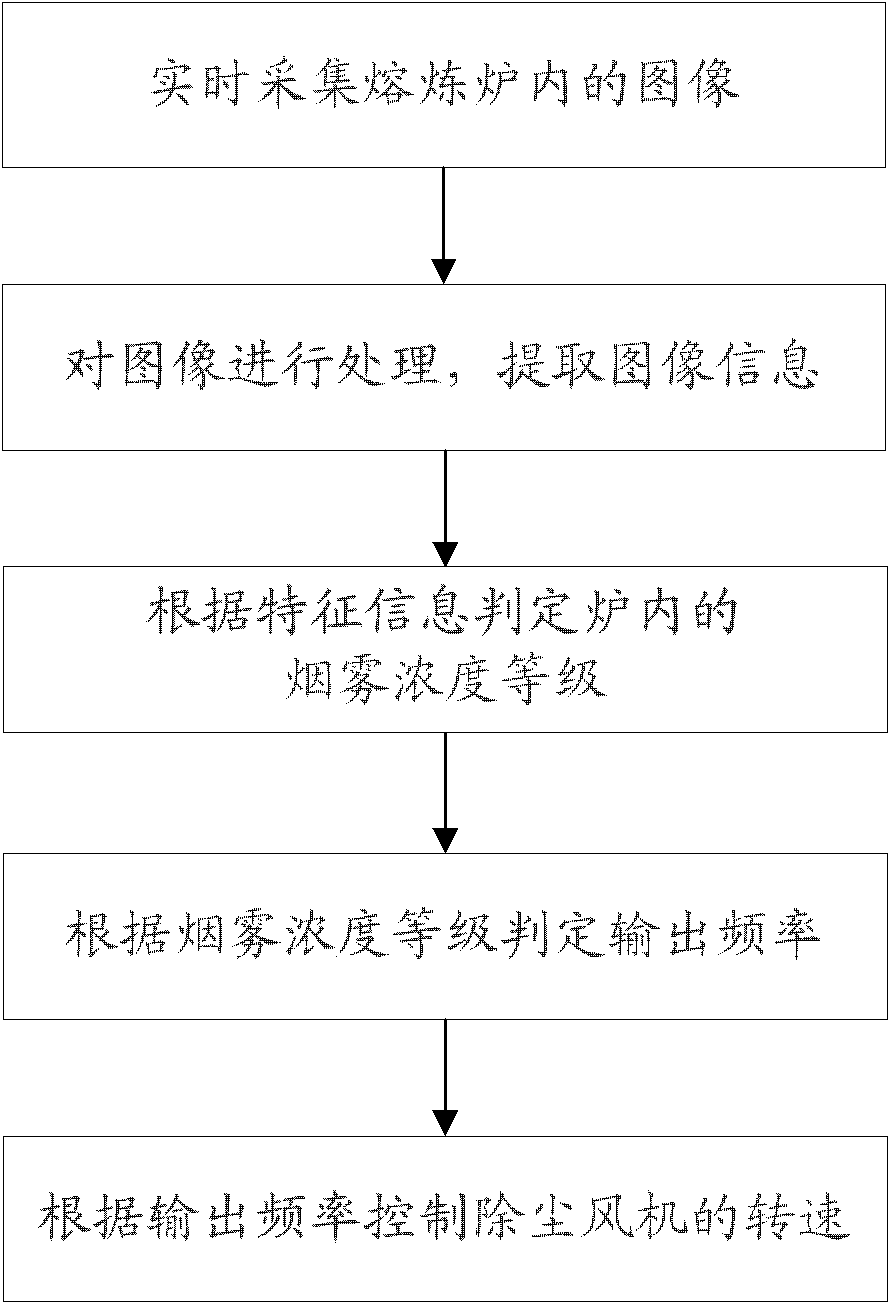

[0046] Such as figure 1 As shown, a control method for energy saving of dust removal fan of industrial frequency smelting furnace includes the following steps:

[0047] (1) Real-time acquisition of images inside the melting furnace.

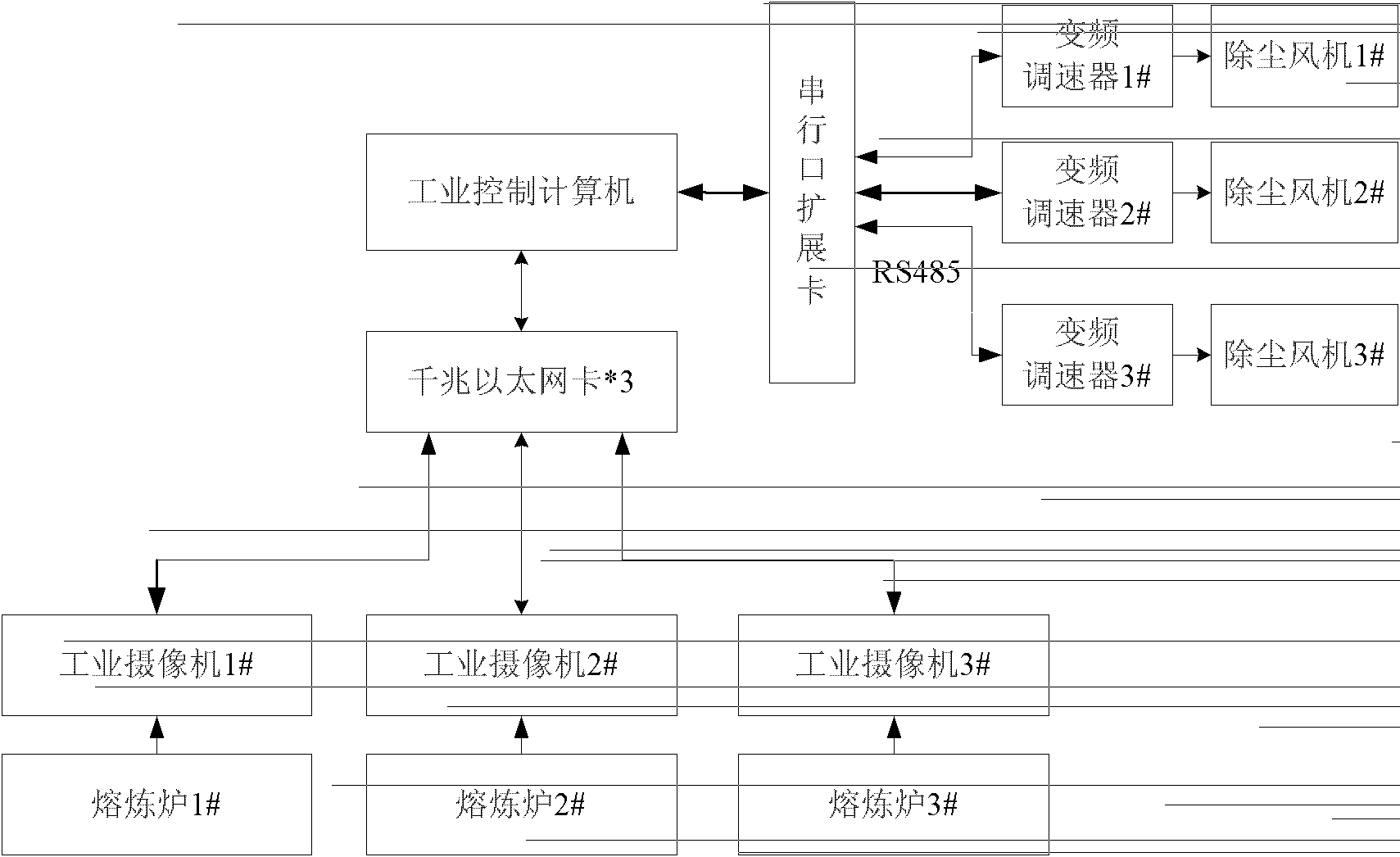

[0048] At a certain moment, the images in the three melting furnaces are respectively collected as image 1, image 2, and image 3.

[0049] (2) Process the image and extract feature information.

[0050]Since there is no stable light source in the furnace itself, the quality of images collected under different lighting conditions is uneven. At the same time, it can be observed that when the smoke and dust are thick, most of them appear under the condition of violent combustion in the furnace. For example, when adding mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com