Adhesion safety detecting method of tower crane

A technology of tower crane and detection method, which is applied in the testing, measuring device, instrument and other directions of machine/structural components, can solve the difficulty of modification, lack of tower crane attachment device and tower body strength, stiffness check, and tower crane safety Sexual Influence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

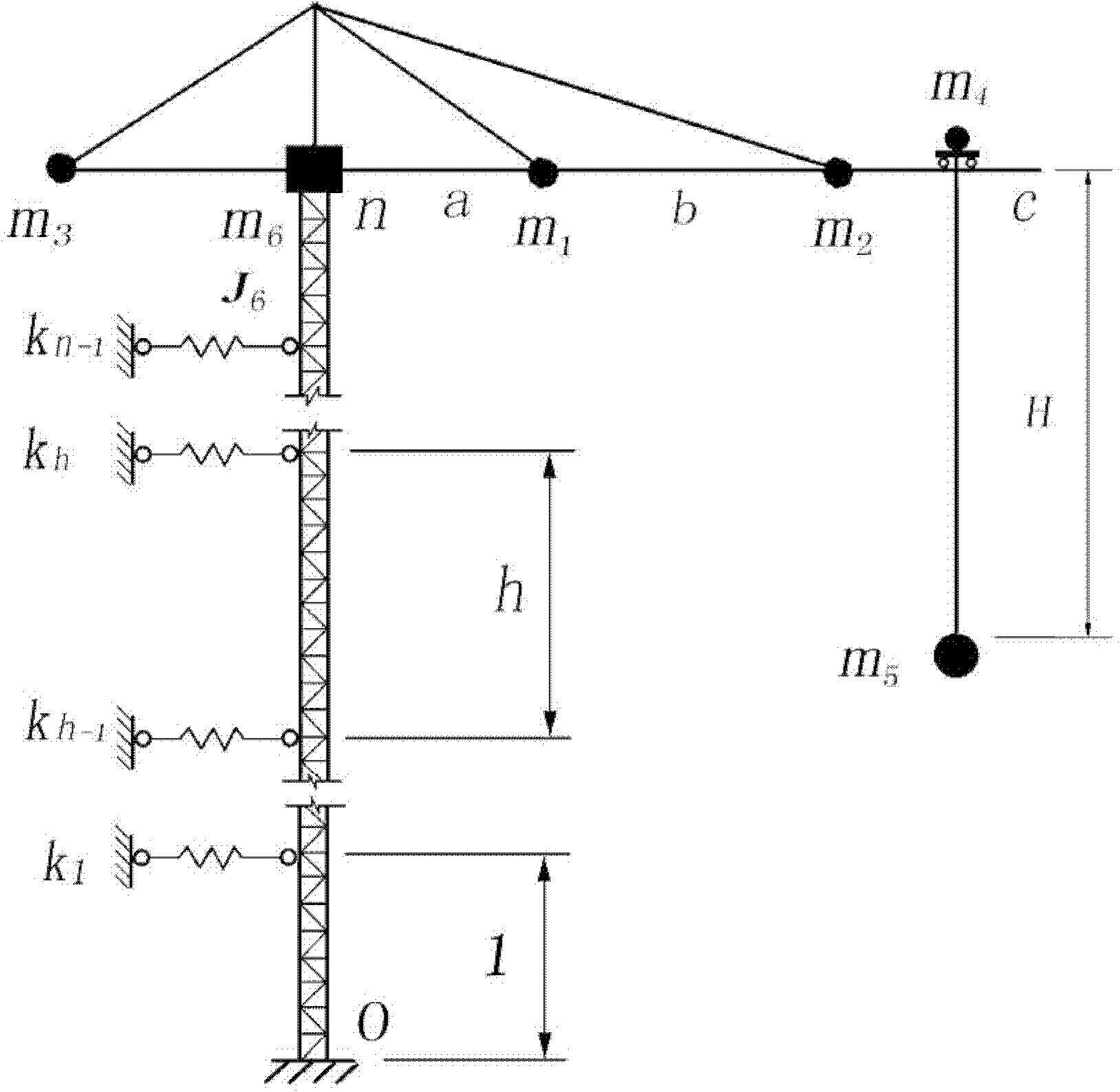

[0074] (1) Establishment of the vibration mathematical model of the tower crane system

[0075] The invention uses the transfer matrix method and the flexibility method to establish the vibration mathematical model of the substructure of the tower body and the tower top system in the hoisting amplitude plane; the frequency equation of the tower crane is established by using the motion and dynamic coordination conditions of the substructure combined interface. A simplified schematic diagram of the mathematical structure model of the tower crane is shown in figure 1 . Through this mathematical structure model, the force transmission relationship between the top system of the tower crane and the position of the tower body and attachment devices can be determined.

[0076] 1-1. Establish the vibration mathematical model of the tower body structure by using the transfer matrix method:

[0077] The structure of the tower body keeps the lattice-type compression-bending structure un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com