Hardware fitting for detecting mechanical property of bar material and using method thereof

A technology of mechanics and performance, applied in the field of metal fittings for bar mechanical performance testing, can solve problems such as poor shear resistance, limited application and promotion of materials, and large bending radius of profiles, so as to avoid stress concentration, strong operability, The effect of easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

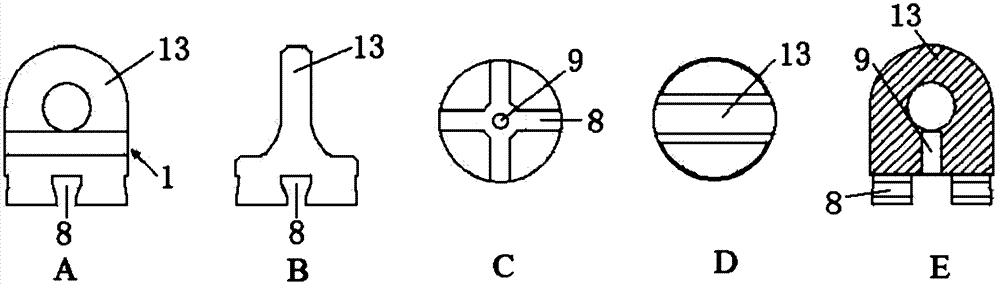

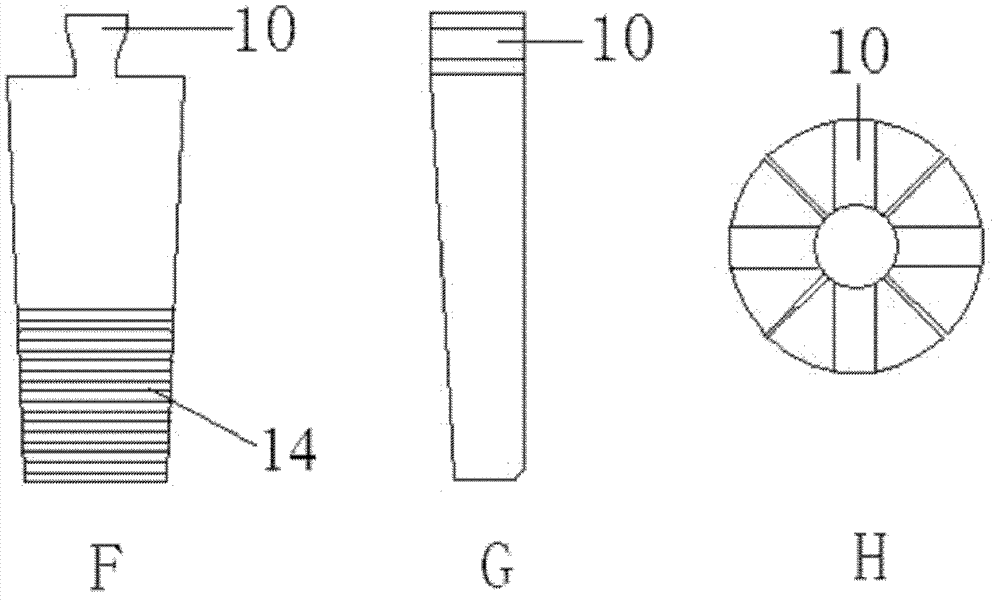

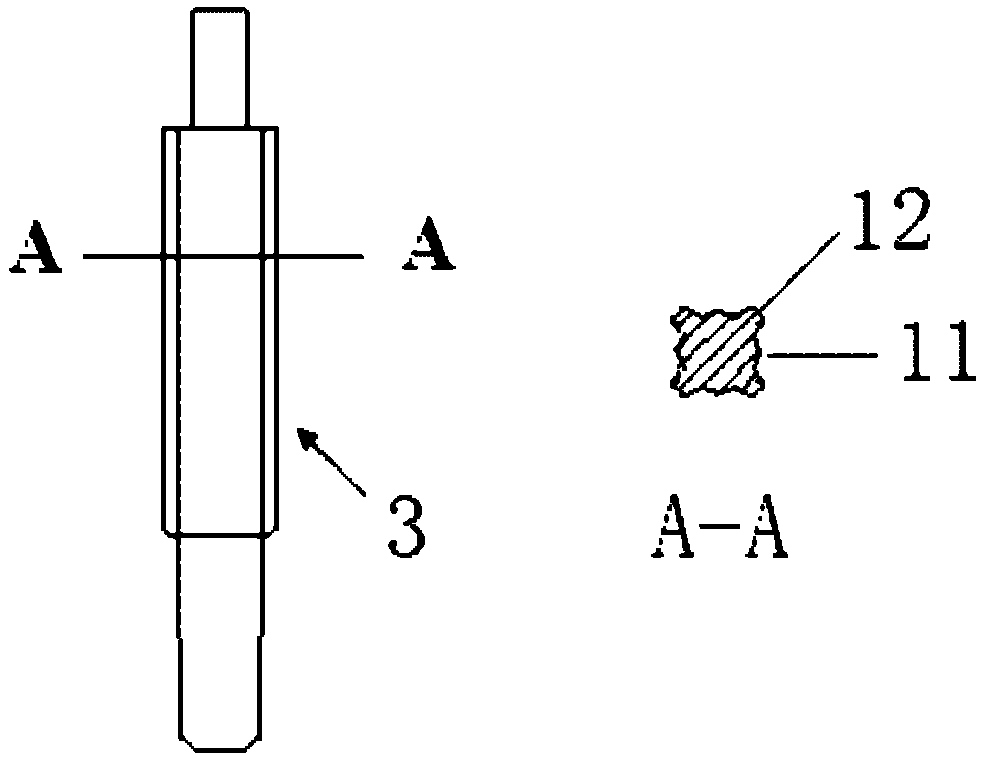

[0042] A metal fitting for detecting the mechanical properties of a bar, which includes a base 1, a briquetting block 2, a mandrel 3 and an inner tapered nut 4, such as figure 1 As shown, the upper part of the base 1 is provided with a connector 13, a plurality of draw-in slots 8 are evenly divided around the lower part, and an inner screw hole 9 is provided at the center of the bottom surface; as image 3 and Figure 5 As shown, the upper end of the mandrel 3 is threadedly connected with the inner screw hole 9, and the center line of the mandrel 3 coincides with the center line of the base 1, and the outer surface of the mandrel 3 is equally divided into a plurality of convex surfaces with the same shape. In the clamping area 11, a boss 12 is provided between every two convex clamping areas 11, and the number of the convex clamping areas 11 matches the number of the card groove 8 and the pressing block 2 respectively; as figure 2 and Figure 5 As shown, the briquetting blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com