A high-strength plastic titanium alloy resistant to high temperature oxidation at 800 ℃

A high-temperature oxidation and titanium alloy technology, applied in the field of new materials, can solve the problem that the operating temperature cannot exceed 600°C, and achieve the effects of excellent high-temperature oxidation resistance, excellent comprehensive performance, and excellent high-temperature oxidation resistance at 800°C

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

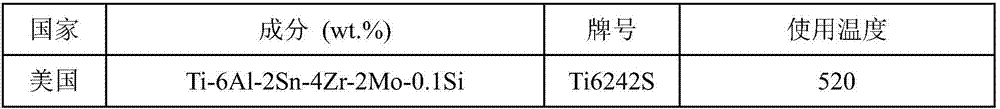

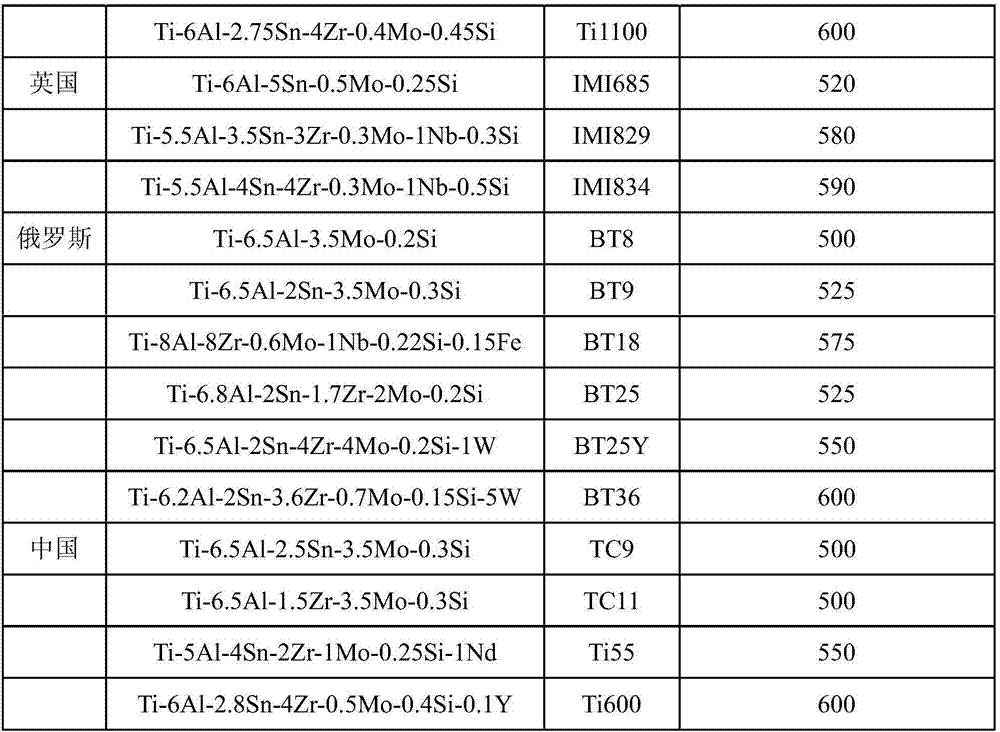

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Ti 86.47 Al 6.01 Sn 2.82 Zr 3.61 Ta 0.72 Si 0.37 alloy

[0015] Step 1: Alloy Preparation

[0016] Ti 86.47 Al 6.01 Sn 2.82 Zr 3.61 Ta 0.72 Si 0.37 alloy, the composition is derived from the cluster type [Al-(Ti 13.7 Zr 0.3 )](Al 0.69 Sn 0.18 Si 0.1 Ta 0.03 ). The pure metals of Ti, Al, Sn, Zr, Ta and Si are prepared according to the given alloy weight percentage; Smelting is carried out under the protection, and the smelting is repeated 3 times to obtain an alloy ingot with uniform composition; then the alloy ingot with uniform smelting is finally melted, and the melt is sucked into the cylindrical copper mold cavity by the copper mold suction casting process to obtain a rod with a diameter of 6mm. The φ6mm alloy rod was solution-treated at 950 °C for 1 h, then water quenched, and then aged at 560 °C for 6 h.

[0017] Step 2: Alloy structure and performance testing

[0018] The alloy structure was detected by XRD, and it was determined t...

Embodiment 2

[0019] Example 2: Ti 86.64 Al 6.02 Sn 2.82 Zr 3.61 Ta 0.36 Nb 0.18 Si 0.37 alloy

[0020] Step 1: Alloy Preparation

[0021] Ti 86.64 Al 6.02 Sn 2.82 Zr 3.61 Ta 0.36 Nb 0.18 Si 0.37 Alloy, [Al-(Ti 13.7 Zr 0.3 )](Al 0.69 Sn 0.18 Si 0.1 -Ta 0.015 Nb 0.015 ). Same as step 1 in embodiment 1.

[0022] Step 2: Alloy structure and performance testing

[0023]The structure of the alloy was detected by XRD, and it was determined to be a single HCP-α solid solution structure; its performance parameters were tested by micro Vickers hardness tester, muffle furnace, MTS testing machine and Gamry electrochemical workstation, respectively: hardness HV=378kgf·mm -2 , oxidative weight gain G after oxidation at 800℃ for 100h + =3.9mg / cm 2 , the room temperature tensile strength σ b =1032MPa, tensile strength σ at 650℃ b =580MPa, 650℃ plastic ε%=51%, self-corrosion voltage E in 3.5%NaCl solution corr =-0.23V, corrosion rate R=2.1μm / a.

Embodiment 3

[0024] Example 3: Ti 86.67 Al 6.03 Sn 2.82 Zr 3.62 Mo 0.13 Ta 0.24 Nb 0.12 Si 0.37 alloy

[0025] Step 1: Alloy Preparation

[0026] Ti 86.67 Al 6.03 Sn 2.82 Zr 3.62 Mo 0.13 Ta 0.24 Nb 0.12 Si 0.37 Alloy, [Al-(Ti 13.7 Zr 0.3 )](Al 0.69 Sn 0.18 -Si 0.1 Mo 0.01 Ta 0.01 Nb 0.01 ). Same as step 1 in embodiment 1.

[0027] Step 2: Alloy structure and performance testing

[0028] The alloy structure was detected by XRD, and it was determined to be a single HCP-α solid solution structure; its performance parameters were tested by micro Vickers hardness tester, muffle furnace, MTS testing machine and Gamry electrochemical workstation, respectively: hardness H V =376kgf·mm -2 , oxidative weight gain G after oxidation at 800℃ for 100h + =5.6mg / cm 2 , the room temperature tensile strength σ b =1190MPa, tensile strength σ at 650℃ b =580MPa, 650℃ plastic ε%=60%, self-corrosion voltage E in 3.5%NaCl solution corr =-0.27V, corrosion rate R=1.7μm / a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com