Method for remanufacturing water wall of waste incineration power generation boiler

A technology for power generation boilers and waste incineration, which is applied in manufacturing tools, superimposed layer plating, liquid chemical plating, etc., can solve problems such as tube burst, reduce boiler service life, leakage, etc., and achieve a broad market prospect and low cost for raw materials. , the effect of great market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

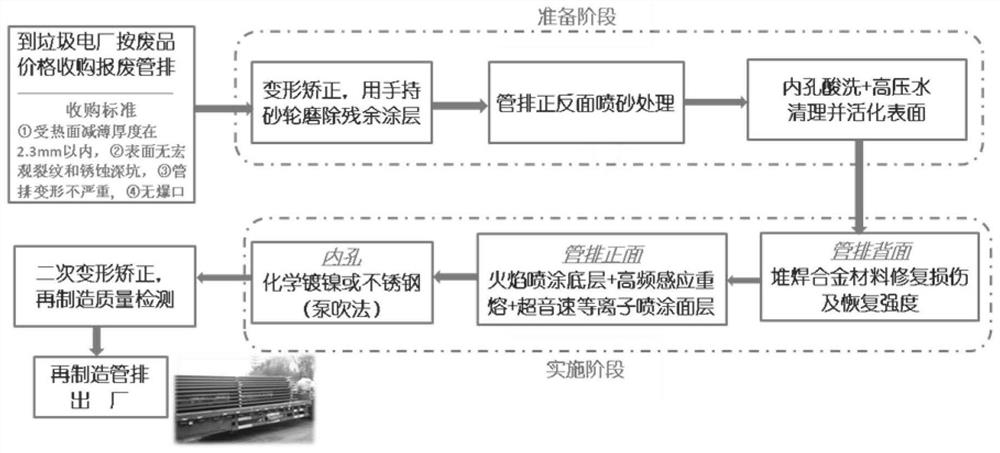

[0028] figure 1 It is the process flow chart of the method for remanufacturing the water-cooled wall of the waste incineration power generation boiler of the present invention, such as figure 1 As shown, the method includes the following:

[0029] (1) Screening of remanufactured blanks

[0030] Go to the garbage power plant to purchase the scrapped pipe row at the waste price, and select the pipe row with no explosion on the heating surface, the overall thermal deformation and the appearance damage of the heating surface are relatively light, and the wall thickness is still more than 2.3mm after thinning ( It accounts for more than 60% of the total scrap pipe row), which is used as a remanufactured blank.

[0031] (2) Turn over to use.

[0032] Since the discarded pipe row is remanufactured and then turned over for use, the heating surface is the back of the original pipe row, and the temperature of this surface is only 100-200 ℃ in the original service environment. Theore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com